At its core, the practical advantage of expanded Polytetrafluoroethylene (ePTFE) gaskets is their ability to dramatically simplify the entire sealing process, from procurement to final installation. They combine the ease of on-site customization with a remarkable ability to conform to imperfect surfaces, creating a reliable seal with less effort.

The most significant installation advantage of ePTFE is its capacity for on-site fabrication. This eliminates the need for pre-ordered, custom-sized gaskets, drastically reducing lead times, inventory complexity, and costs associated with sealing non-standard equipment.

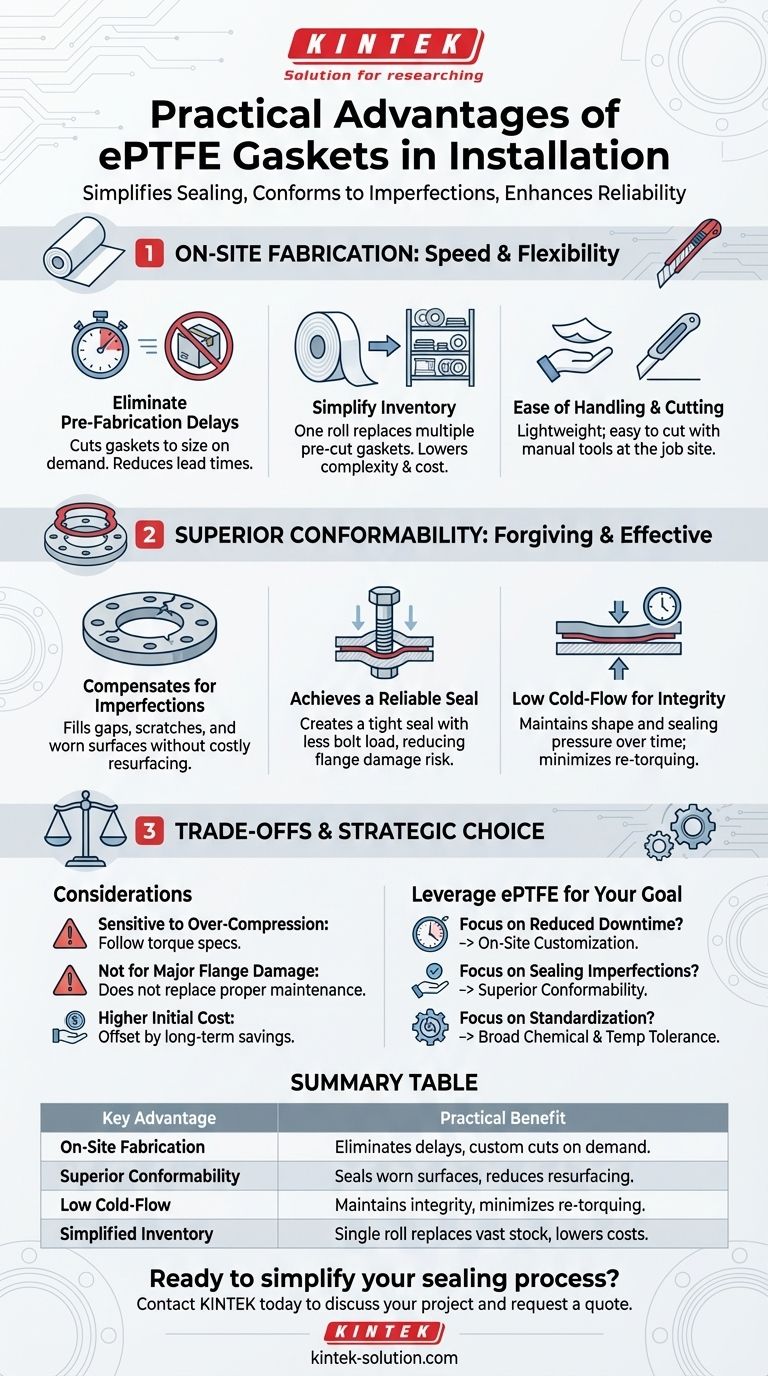

On-Site Fabrication: Speed and Flexibility

One of the most immediate benefits of working with ePTFE gasket material, which typically comes in sheet or tape form, is the ability to bypass traditional procurement cycles.

Eliminating Pre-Fabrication Delays

Instead of measuring a flange, ordering a custom-cut gasket, and waiting for delivery, technicians can create the exact gasket needed on the spot. This is invaluable during time-sensitive repairs and plant shutdowns.

Simplifying Inventory

A single roll or sheet of ePTFE material can replace a vast inventory of pre-cut gaskets of various sizes and shapes. This lowers procurement costs and ensures the right material is always on hand.

Ease of Handling and Cutting

ePTFE is lightweight and easy to manage during transportation and assembly. It can be cut to any desired size or complex shape using simple manual or mechanical tools right at the job site.

Superior Conformability and Forgiveness

The unique manufacturing process of ePTFE creates a multidirectional fibrous structure. This structure is key to its exceptional performance during installation on real-world equipment, which is often not perfectly flat or new.

Compensating for Flange Imperfections

ePTFE excels at filling wide flange gaps, scratches, and other surface irregularities. This adaptability ensures excellent tightness even on worn or damaged equipment, reducing the need for costly flange resurfacing.

Achieving a Reliable Seal

The material's soft, conformable nature allows it to create a tight seal with less bolt load compared to many harder gasket materials. This lowers the risk of flange damage, particularly on delicate or non-metallic equipment.

Low Cold-Flow for Installation Integrity

Despite its softness, ePTFE has a very low tendency toward "cold-flow" or creep. This means that once compressed during installation, it maintains its shape and sealing pressure, ensuring a durable, long-lasting seal without the need for frequent re-torquing.

Understanding the Trade-offs

While highly advantageous, ePTFE is not a universal solution. Understanding its limitations is critical for successful application and avoiding installation errors.

Sensitivity to Over-Compression

The softness that makes ePTFE so conformable also makes it susceptible to damage from over-torquing. It is essential to follow manufacturer specifications for bolt torque to avoid crushing the material and compromising the seal.

Not a Substitute for Proper Flange Assesment

While ePTFE is forgiving, it cannot fix major flange damage. It is a tool for managing minor imperfections, not a replacement for proper equipment maintenance and engineering review.

Higher Initial Material Cost

The initial purchase price of ePTFE material can be higher than conventional rubber or plastic sealing products. However, this cost is often offset by its long service life and significant savings in reduced inventory, labor, and downtime.

Making the Right Choice for Your Goal

Selecting ePTFE is a strategic decision that should be aligned with your operational priorities.

- If your primary focus is reducing downtime and maintenance inventory: The ability to cut any gasket to size on-site makes ePTFE an unmatched solution for simplifying logistics and speeding up repairs.

- If your primary focus is sealing old, worn, or imperfect equipment: The superior conformability of ePTFE provides a highly reliable seal where other, more rigid gaskets might fail.

- If your primary focus is standardizing sealing materials: The broad chemical resistance and temperature tolerance of ePTFE allow it to be used in a vast range of applications, simplifying material selection and training.

Ultimately, leveraging ePTFE gaskets transforms sealing from a reactive task into a proactive, efficient, and reliable process.

Summary Table:

| Key Advantage | Practical Benefit |

|---|---|

| On-Site Fabrication | Eliminates pre-fabrication delays; cuts gaskets to size on demand. |

| Superior Conformability | Seals effectively on worn or imperfect flanges, reducing resurfacing needs. |

| Low Cold-Flow | Maintains sealing integrity after installation, minimizing re-torquing. |

| Simplified Inventory | A single roll replaces a vast stock of pre-cut gaskets, lowering costs. |

Ready to simplify your sealing process and reduce downtime?

At KINTEK, we specialize in manufacturing high-performance PTFE and ePTFE components, including custom gaskets, seals, and liners. Our expertise in precision fabrication—from prototypes to high-volume orders—ensures you get the exact sealing solution your application demands, whether for semiconductor, medical, laboratory, or industrial use.

Leverage our materials to achieve faster installations, superior seals on imperfect surfaces, and significant inventory savings. Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE coatings used in the aerospace industry? Ensuring Reliability in Extreme Conditions

- How can PTFE lined butterfly valves be customized for different applications? Tailor Valves for Your Specific Needs

- What are the advantages of polyester-filled PTFE? A Guide to Superior Wear & Load Performance

- What are the advantages of stainless steel filler in PTFE? Boost Strength & Performance for Demanding Applications

- What are the key benefits of Medical Grade PTFE Liners in healthcare? Enhancing Patient Safety & Device Performance

- What shapes and forms are PTFE washers available in? From Standard Circles to Custom Profiles

- What electrical insulation benefits do PTFE gaskets provide? Unmatched Protection for Harsh Environments

- How does the compressibility of ePTFE gaskets benefit sealing applications? Achieve Superior, Leak-Free Seals