In short, Polytetrafluoroethylene (PTFE) coatings are used in the aerospace industry to ensure critical components remain reliable under extreme conditions. Its unique combination of properties—including extreme temperature resistance, chemical inertness, and low friction—makes it essential for applications ranging from electrical wire insulation and engine seals to hydraulic fluid lines and mechanical gears.

The core reason PTFE is indispensable in aerospace is its ability to guarantee operational integrity. In an environment where failure is not an option, PTFE acts as a safeguard, protecting systems from extreme temperatures, corrosive fluids, and friction-induced wear.

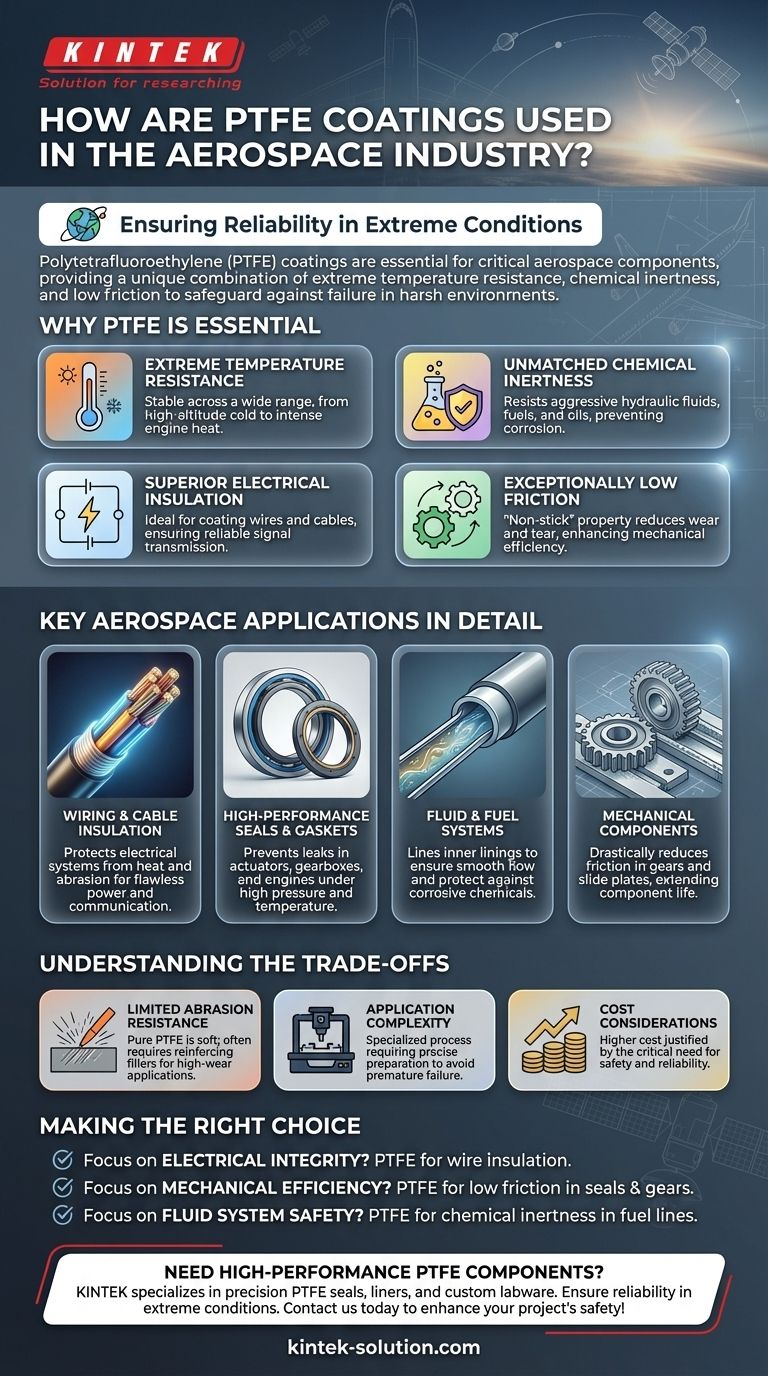

Why PTFE is Essential for Aerospace Reliability

The value of PTFE in aerospace engineering stems from a few core properties that allow it to perform consistently in the harshest environments imaginable, from the vacuum of space to the high temperatures of a jet engine.

Extreme Temperature Resistance

PTFE maintains its stability across an incredibly wide temperature range. This allows it to function flawlessly in components exposed to both high-altitude cold and the intense friction-generated heat found in engines and landing gear.

Unmatched Chemical Inertness

Aerospace systems rely on aggressive hydraulic fluids, fuels, and oils. PTFE's chemical resistance prevents corrosion and degradation, ensuring the integrity of seals, gaskets, and fluid lines that would otherwise fail.

Superior Electrical Insulation

Reliable communication and control systems are paramount for flight safety. PTFE is an exceptional electrical insulator, making it the ideal material for coating wires and cables, preventing short circuits and ensuring consistent signal transmission.

Exceptionally Low Friction

PTFE has one ofthe lowest coefficients of friction of any solid material. This "non-stick" property is critical for preventing debris buildup and reducing wear in moving parts, ensuring the smooth operation of actuators, gearboxes, and other mechanical systems.

Key Aerospace Applications in Detail

These fundamental properties translate into specific, high-stakes applications throughout an aircraft where performance and safety are non-negotiable.

Wiring and Cable Insulation

PTFE coating is the standard for high-performance aerospace wires. It protects critical electrical systems from heat and abrasion, ensuring that power distribution, communication, and control networks operate without failure.

High-Performance Seals and Gaskets

Seals made from or coated with PTFE are used extensively in systems that cannot tolerate leaks. This includes actuators, gearboxes, turbine engines, fuel systems, and landing gear. Specialized designs like PTFE chevron packing and energized seals provide robust performance under high pressure and temperature fluctuations.

Fluid and Fuel Systems

The inner linings of fuel and hydraulic lines are often coated with PTFE. This ensures the smooth flow of fluids while protecting the lines themselves from the corrosive chemicals they transport, enhancing both safety and system longevity.

Mechanical Components

In components like gears and slide plates, a PTFE coating drastically reduces friction. This minimizes wear and tear, extends the life of the parts, and reduces the energy required to operate them, contributing to overall mechanical efficiency.

Understanding the Trade-offs

While PTFE is a high-performance material, it is not a universal solution. Acknowledging its limitations is key to proper engineering design.

Limited Abrasion Resistance

In its pure form, PTFE is relatively soft. For applications involving significant physical wear, it is often combined with reinforcing fillers (like glass fiber or carbon) to improve its durability and abrasion resistance.

Application Complexity

Applying a PTFE coating is a specialized process that requires precise surface preparation and curing techniques. Improper application can lead to poor adhesion and premature failure, negating the material's benefits.

Cost Considerations

As a high-performance polymer, PTFE is more expensive than many conventional materials. Its use is justified by the critical need for safety and reliability, where the cost of component failure would be catastrophic.

Making the Right Choice for Your Goal

Selecting PTFE is a decision driven by the specific demands of the aerospace component you are designing.

- If your primary focus is electrical system integrity: PTFE's exceptional dielectric strength and thermal stability are the most critical factors for wire and cable insulation.

- If your primary focus is mechanical efficiency and longevity: Its ultra-low coefficient of friction is the key property for reducing wear in seals, actuators, and gears.

- If your primary focus is fluid system safety: PTFE's unparalleled chemical inertness makes it the only choice for components exposed to aggressive fuels and hydraulic fluids.

Ultimately, PTFE's role in aerospace is to provide certainty in environments defined by uncertainty.

Summary Table:

| PTFE Property | Key Aerospace Application |

|---|---|

| Extreme Temperature Resistance | Engine seals, landing gear components |

| Chemical Inertness | Fuel & hydraulic fluid line linings |

| Electrical Insulation | Wiring & cable coatings for critical systems |

| Low Friction | Gears, actuators, and mechanical components |

Need high-performance PTFE components for your aerospace applications? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure reliability in extreme conditions with custom fabrication from prototypes to high-volume orders. Contact us today to discuss how our PTFE solutions can enhance your project's safety and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What advantages do PTFE slide bearings offer in terms of corrosion and heat loss? Boost System Longevity & Efficiency

- Why is high temperature stability important for Teflon gland fillers? Ensuring Leak-Free Seals in Harsh Chemical Processes

- What are the thermal and electrical performance characteristics of Teflon PTFE? Master Its Properties for Demanding Applications

- What industries benefit from using pure PTFE in valve components and why? Ensure Absolute Purity in Critical Processes

- Are expanded PTFE gaskets as durable as standard PTFE gaskets? Discover the Best Choice for Your Seal.

- How does the machining process for Teflon differ from machining metals? A Guide to Precision and Finesse

- What advantages does PTFE packing provide? Superior Chemical Resistance, Low Friction & Thermal Stability

- What manufacturing methods are used to produce custom PTFE products? A Guide to Molding and Machining