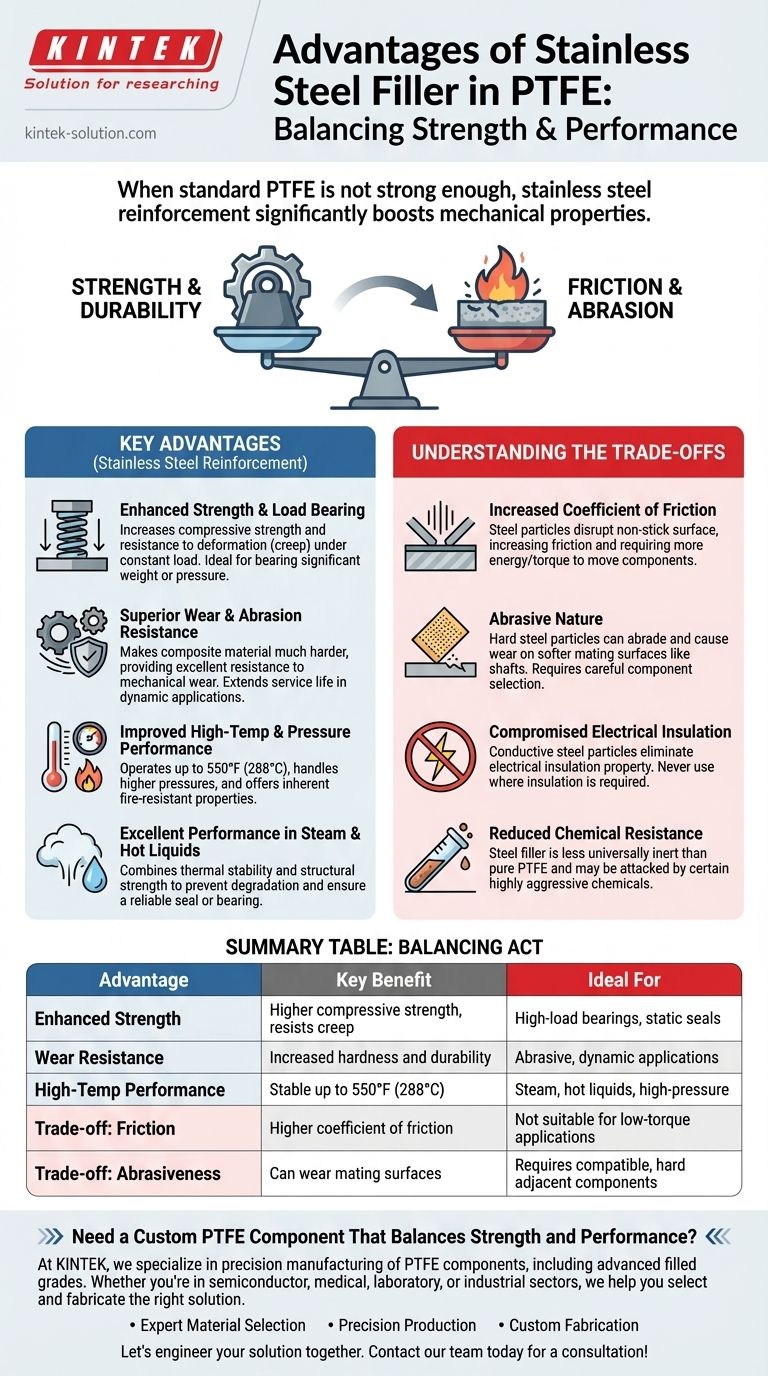

When standard PTFE is not strong enough, adding stainless steel filler is the solution for dramatically improving its mechanical properties. This reinforcement significantly increases resistance to wear, compressive load, and high temperatures, making it a superior choice for demanding applications, especially those involving steam, hot liquids, or heavy loads.

The core advantage of stainless steel-filled PTFE is a significant boost in physical strength and thermal stability. However, this enhancement comes with a critical trade-off: increased friction and the potential to wear down adjacent components.

Key Advantages of Stainless Steel Reinforcement

Polytetrafluoroethylene (PTFE) is known for its low friction and chemical inertness, but it is a relatively soft material. The addition of powdered stainless steel creates a composite material with fundamentally improved physical characteristics.

Enhanced Strength and Load Bearing

The steel particles distributed throughout the PTFE matrix act as a structural reinforcement. This significantly increases the material's compressive strength and its ability to resist deformation or "creep" under a constant load.

This makes it ideal for components that must bear significant weight or pressure without changing shape.

Superior Wear and Abrasion Resistance

Virgin PTFE can wear quickly in abrasive conditions. Stainless steel filler makes the composite material much harder and more durable, providing excellent resistance to mechanical wear.

This extends the service life of parts used in dynamic applications with rubbing or sliding contact.

Improved High-Temperature and Pressure Performance

The inclusion of steel raises the material's performance ceiling. Stainless steel-filled PTFE can operate at slightly higher temperatures (up to 550°F or 288°C) and handle significantly higher pressures than unfilled PTFE.

It also possesses inherent fire-resistant properties, a critical advantage in certain industries.

Excellent Performance in Steam and Hot Liquids

This material excels in environments with steam or hot water. Its combination of thermal stability and structural strength prevents degradation and ensures a reliable seal or bearing surface in these challenging conditions.

Understanding the Trade-offs

While the mechanical benefits are clear, reinforcing PTFE with stainless steel introduces compromises that are critical to understand for proper material selection.

Increased Coefficient of Friction

The primary benefit of virgin PTFE is its extremely low friction. Adding steel particles increases the coefficient of friction, disrupting the non-stick surface.

This means more energy, or torque, is required to move components. For example, in a valve, this translates to a higher stem torque needed for operation.

Abrasive Nature

This is the most significant drawback. The hard stainless steel particles can abrade and cause wear on softer mating surfaces, such as shafts, stems, or housings.

Careful consideration must be given to the hardness of all adjacent components to prevent premature failure of the overall assembly.

Compromised Electrical Insulation

Virgin PTFE is an outstanding electrical insulator. The addition of conductive stainless steel particles eliminates this property entirely. Stainless steel-filled PTFE should never be used in applications requiring electrical insulation.

Reduced Chemical Resistance

While 316 stainless steel offers excellent corrosion resistance, it is not as universally inert as pure PTFE. In the presence of certain highly aggressive chemicals, the steel filler may be attacked, compromising the material's integrity.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal.

- If your primary focus is maximum strength and high-temperature performance: Stainless steel-filled PTFE is an excellent choice for static seals, valve seats, or high-load bearings.

- If your primary focus is low friction and protecting mating surfaces: You should specify virgin PTFE or a variant with a less abrasive filler, such as bronze or graphite.

- If your primary focus is universal chemical inertness or electrical insulation: You must use virgin PTFE, as stainless steel fillers negate these core properties.

Ultimately, choosing stainless steel-filled PTFE means prioritizing mechanical robustness for the most demanding physical environments.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Enhanced Strength | Higher compressive strength, resists creep | High-load bearings, static seals |

| Wear Resistance | Increased hardness and durability | Abrasive, dynamic applications |

| High-Temp Performance | Stable up to 550°F (288°C) | Steam, hot liquids, high-pressure environments |

| Trade-off: Friction | Higher coefficient of friction | Not suitable for low-torque applications |

| Trade-off: Abrasiveness | Can wear mating surfaces | Requires compatible, hard adjacent components |

Need a Custom PTFE Component That Balances Strength and Performance?

At KINTEK, we specialize in precision manufacturing of PTFE components, including advanced filled grades like stainless steel-reinforced PTFE. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you select the right material and fabricate a solution that meets your exact needs—from prototypes to high-volume production.

We deliver:

- Expert Material Selection: We'll help you choose between virgin PTFE, stainless steel-filled, or other compounds to optimize for strength, wear, friction, or chemical resistance.

- Precision Production: Our manufacturing ensures your components perform reliably under demanding conditions.

- Custom Fabrication: We tailor parts to your specifications, ensuring perfect fit and function.

Let's engineer your solution together. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs