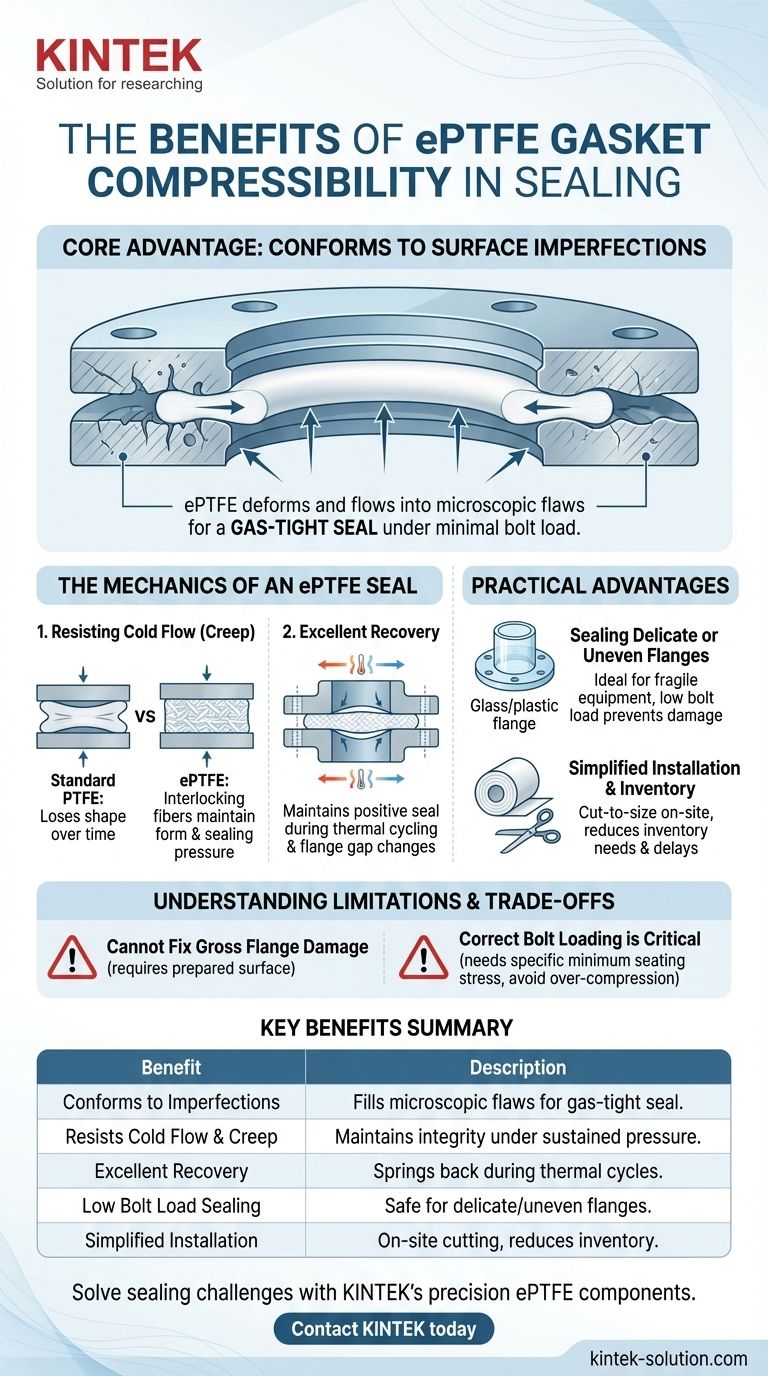

At its core, the high compressibility of an expanded PTFE (ePTFE) gasket is what allows it to create a reliable seal where other materials might fail. This property enables the soft, malleable material to physically deform and flow into the microscopic scratches, pits, and waviness present on virtually all flange surfaces, ensuring a complete and gas-tight seal even with minimal bolt force.

The primary benefit of ePTFE's compressibility is not just its softness, but its ability to create a perfect "formed-in-place" seal. It compensates for real-world surface imperfections and maintains that seal over time by resisting the plastic deformation, or "creep," that plagues standard gaskets.

The Mechanics of an ePTFE Seal

To fully appreciate the advantage of ePTFE, we must look beyond the surface and understand the physical principles at play. The unique manufacturing process of ePTFE creates a multidirectional fibrous structure that gives it properties distinct from solid PTFE.

Conforming to Surface Imperfections

Most sealing failures occur because of tiny, unseen leak paths. ePTFE's high compressibility directly solves this problem. Under initial bolt load, the material easily deforms, acting almost like a solid liquid to fill every void, tool mark, and irregularity on a flange face.

This is especially critical for older, worn, or less-precisely-machined surfaces where a rigid gasket would only make contact on the high points, leaving gaps for leaks to form.

Resisting Cold Flow and Creep

Cold flow, or creep, is the tendency of a material to slowly deform and lose its shape under sustained pressure. Standard PTFE is highly susceptible to this; over time, it will "squish" out of the flange, causing a loss of bolt tension and seal integrity.

The fibrous, expanded structure of ePTFE is engineered to resist this. The interlocking fibers provide structural stability, ensuring the gasket maintains its form and sealing pressure even under continuous load and temperature changes. This results in a highly durable and reliable long-term seal.

Excellent Recovery Properties

Real-world systems experience pressure and temperature cycles. As flanges heat up, they expand; as they cool, they contract. A gasket must be able to "breathe" with the system.

ePTFE exhibits excellent recovery, meaning it can spring back after being compressed. This allows it to maintain a constant, positive seal even as the flange gap changes during thermal cycling, a condition where more rigid gaskets would quickly fail.

Practical Advantages in the Field

The mechanical properties of ePTFE translate directly into tangible benefits during installation and operation, solving common engineering challenges.

Sealing Delicate or Uneven Flanges

The ability to create a seal with low bolt load makes ePTFE ideal for fragile equipment. Applications involving glass-lined steel, ceramics, or plastic flanges can be sealed effectively without the risk of cracking the flange from excessive torque.

Similarly, it is highly effective on large-diameter or slightly warped steel flanges where achieving perfectly uniform bolt pressure is difficult. The gasket compensates for the inconsistencies.

Simplified Installation and Inventory

ePTFE is often supplied in sheet form or as a "joint sealant" tape. This allows maintenance teams to cut any size or shape of gasket on-site, dramatically reducing the need to stock hundreds of pre-cut gaskets.

This flexibility lowers inventory costs, simplifies procurement, and eliminates project delays caused by waiting for a specific, non-standard gasket to arrive.

Understanding the Limitations and Trade-offs

While highly effective, ePTFE is not a universal solution. Its benefits are only realized when its properties are correctly matched to the application and proper procedures are followed.

It Cannot Fix Gross Flange Damage

ePTFE's compressibility is designed to handle microscopic surface irregularities. It cannot compensate for major flange damage, deep gouges, significant warping, or severe misalignment. The foundation of any seal is a properly prepared and aligned flange surface.

Correct Bolt Loading is Critical

The phrase "low bolt load" does not mean "no bolt load." While ePTFE requires less force than many materials, it still needs a specific minimum seating stress to initiate a seal. Following manufacturer specifications for torque is essential.

Over-compressing the gasket can damage its internal fibrous structure, reducing its ability to recover and potentially leading to premature failure. Controlled, uniform bolt tightening is non-negotiable.

Differentiating from Standard PTFE

It is crucial to distinguish between standard, solid PTFE and expanded PTFE (ePTFE). While standard PTFE offers excellent chemical resistance, it suffers from high creep and poor recovery. ePTFE is specifically engineered to solve these mechanical failings while retaining the same superior chemical resistance.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the material's strengths to your primary goal.

- If your primary focus is sealing old, damaged, or delicate flanges: ePTFE's exceptional conformability under low bolt load is its single greatest advantage.

- If your primary focus is reliability under fluctuating temperatures or pressures: Its excellent recovery and low cold-flow properties ensure a durable, long-term seal that moves with your system.

- If your primary focus is simplifying maintenance and reducing inventory: The ability to cut gaskets from a sheet on-site makes ePTFE a highly cost-effective and operationally flexible choice.

By leveraging the unique compressibility of ePTFE, you can solve challenging sealing problems that other materials simply cannot address.

Summary Table:

| Key Benefit | Description |

|---|---|

| Conforms to Imperfections | Deforms to fill microscopic scratches and pits on flange surfaces for a gas-tight seal. |

| Resists Cold Flow & Creep | Maintains seal integrity under sustained pressure and temperature changes, unlike standard PTFE. |

| Excellent Recovery | Springs back during thermal cycling to maintain a constant seal as flanges expand and contract. |

| Low Bolt Load Sealing | Ideal for delicate flanges (glass, plastic) and large, uneven surfaces without risk of damage. |

| Simplified Installation | Can be cut on-site from sheets or tape, reducing inventory needs and project delays. |

Solve your most challenging sealing problems with KINTEK's precision ePTFE components.

Our expanded PTFE (ePTFE) gaskets, seals, and custom fabrications are engineered to deliver the superior compressibility, recovery, and chemical resistance detailed in this article. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK prioritizes precision production to ensure your critical applications achieve leak-free reliability, even on imperfect or delicate surfaces.

We offer custom fabrication from prototypes to high-volume orders, providing the exact solution you need.

Contact KINTEK today to discuss your specific sealing requirements and let our experts provide a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components