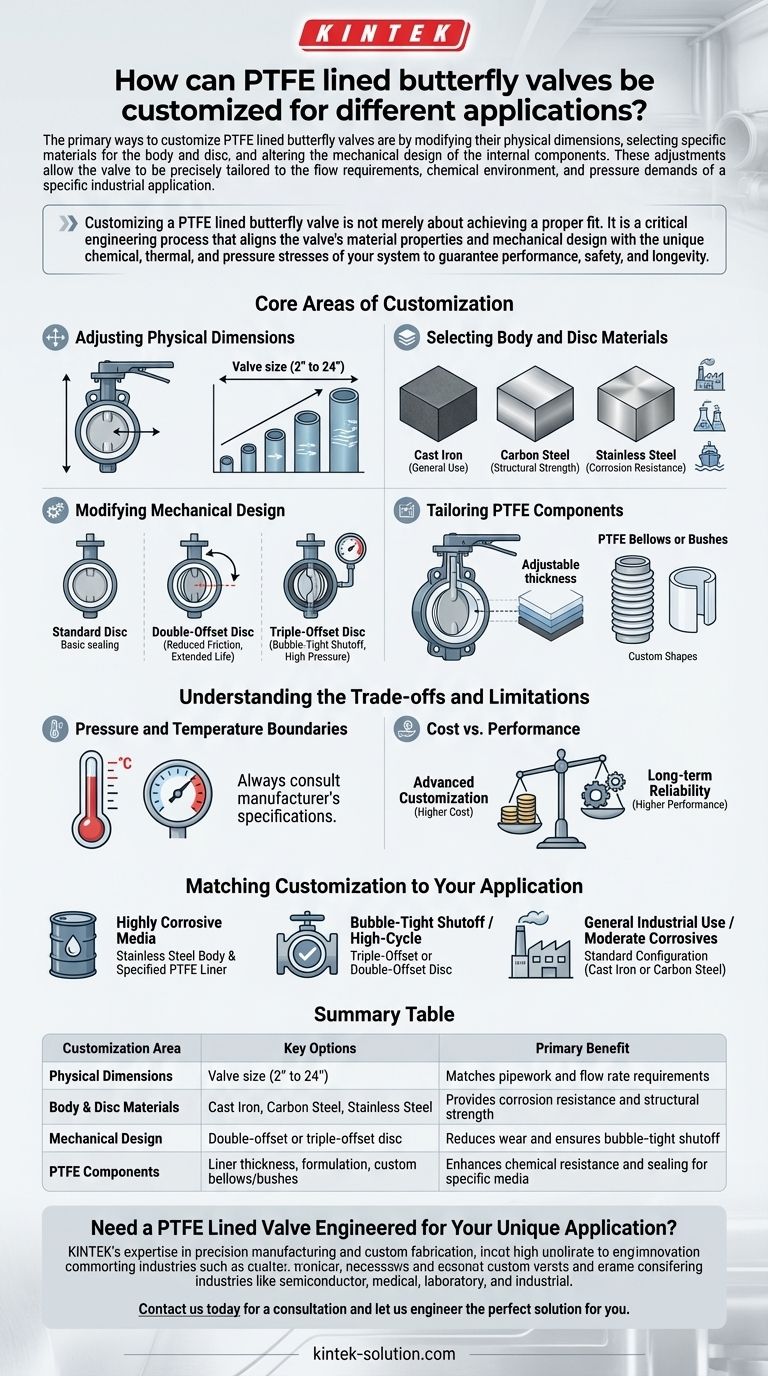

The primary ways to customize PTFE lined butterfly valves are by modifying their physical dimensions, selecting specific materials for the body and disc, and altering the mechanical design of the internal components. These adjustments allow the valve to be precisely tailored to the flow requirements, chemical environment, and pressure demands of a specific industrial application.

Customizing a PTFE lined butterfly valve is not merely about achieving a proper fit. It is a critical engineering process that aligns the valve's material properties and mechanical design with the unique chemical, thermal, and pressure stresses of your system to guarantee performance, safety, and longevity.

Core Areas of Customization

To select the right valve, you must understand the key levers available for customization. Each one addresses a different operational challenge, from chemical compatibility to sealing integrity.

Adjusting Physical Dimensions

The most fundamental customization is valve size. Valves are available in a wide range of standard sizes, typically from 2 to 24 inches, to match different pipe dimensions and accommodate specific flow rate requirements.

Selecting Body and Disc Materials

The valve's external body and internal disc materials are chosen based on the application's environment. Common options include cast iron, carbon steel, and stainless steel.

The choice is driven by the need for corrosion resistance, structural strength, and cost-effectiveness. A stainless steel body, for example, is ideal for highly corrosive environments, while cast iron may be sufficient for less demanding applications.

Modifying Mechanical Design

The internal design of the disc significantly impacts performance. A double-offset disc design, for instance, reduces friction and wear during operation, extending the valve's service life.

For applications requiring absolute sealing, a triple-offset design can be specified. This advanced configuration provides a "bubble-tight" shutoff, which is critical in high-pressure systems or when handling hazardous materials.

Tailoring PTFE Components

While the body and disc provide structure, the PTFE components deliver the chemical resistance and sealing. The thickness and formulation of the PTFE liner itself can be adapted.

Furthermore, associated components like PTFE bellows or bushes can be manufactured in custom shapes, sizes, and wall thicknesses to meet highly specialized operational demands and improve overall system efficiency.

Understanding the Trade-offs and Limitations

While highly versatile, customized PTFE lined valves are not a universal solution. Understanding their inherent trade-offs is essential for proper specification.

Pressure and Temperature Boundaries

PTFE valves are suitable for many high-pressure applications, but they have limits. The maximum allowable pressure and temperature are dictated by the valve's specific design, materials, and construction.

It is critical to always consult the manufacturer’s specifications to ensure the chosen valve can safely handle the operational parameters of your system.

Cost vs. Performance

Advanced customization comes at a price. High-performance materials like stainless steel and complex mechanisms like triple-offset discs significantly increase the valve's cost compared to standard configurations.

The goal is to specify a valve that meets the application's requirements without over-engineering, balancing long-term reliability against upfront investment.

Matching Customization to Your Application

Use your primary operational goal to guide your customization choices.

- If your primary focus is handling highly corrosive media: Prioritize a stainless steel body and ensure the PTFE liner is specified for the specific chemicals involved.

- If your primary focus is bubble-tight shutoff or high-cycle applications: Specify a triple-offset or double-offset disc design to ensure sealing integrity and minimize wear.

- If your primary focus is general industrial use with moderate corrosives: A standard configuration with a cast iron or carbon steel body often provides the most cost-effective solution.

Thoughtful customization transforms a standard component into a precisely engineered solution for your specific challenge.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Physical Dimensions | Valve size (2" to 24") | Matches pipework and flow rate requirements |

| Body & Disc Materials | Cast iron, carbon steel, stainless steel | Provides corrosion resistance and structural strength |

| Mechanical Design | Double-offset or triple-offset disc | Reduces wear and ensures bubble-tight shutoff |

| PTFE Components | Liner thickness, formulation, custom bellows/bushes | Enhances chemical resistance and sealing for specific media |

Need a PTFE Lined Valve Engineered for Your Unique Application?

At KINTEK, we specialize in the precision manufacturing and custom fabrication of high-performance PTFE components, including seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our team can tailor a PTFE lined butterfly valve to your exact specifications—from prototypes to high-volume orders.

We ensure your valve delivers optimal performance, safety, and longevity by aligning its design with your specific chemical, thermal, and pressure demands.

Contact us today for a consultation and let us engineer the perfect solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry