At their core, PTFE-lined bearings provide three primary benefits: they are self-lubricating, they offer an extremely low coefficient of friction, and they exhibit excellent chemical and thermal resistance. This combination makes them ideal for applications where external lubrication is impractical, undesirable, or impossible.

The fundamental advantage of a PTFE-lined bearing is its ability to deliver consistent, maintenance-free performance in demanding environments. It solves the problems of contamination, lubricant failure, and stick-slip motion that plague traditionally lubricated systems.

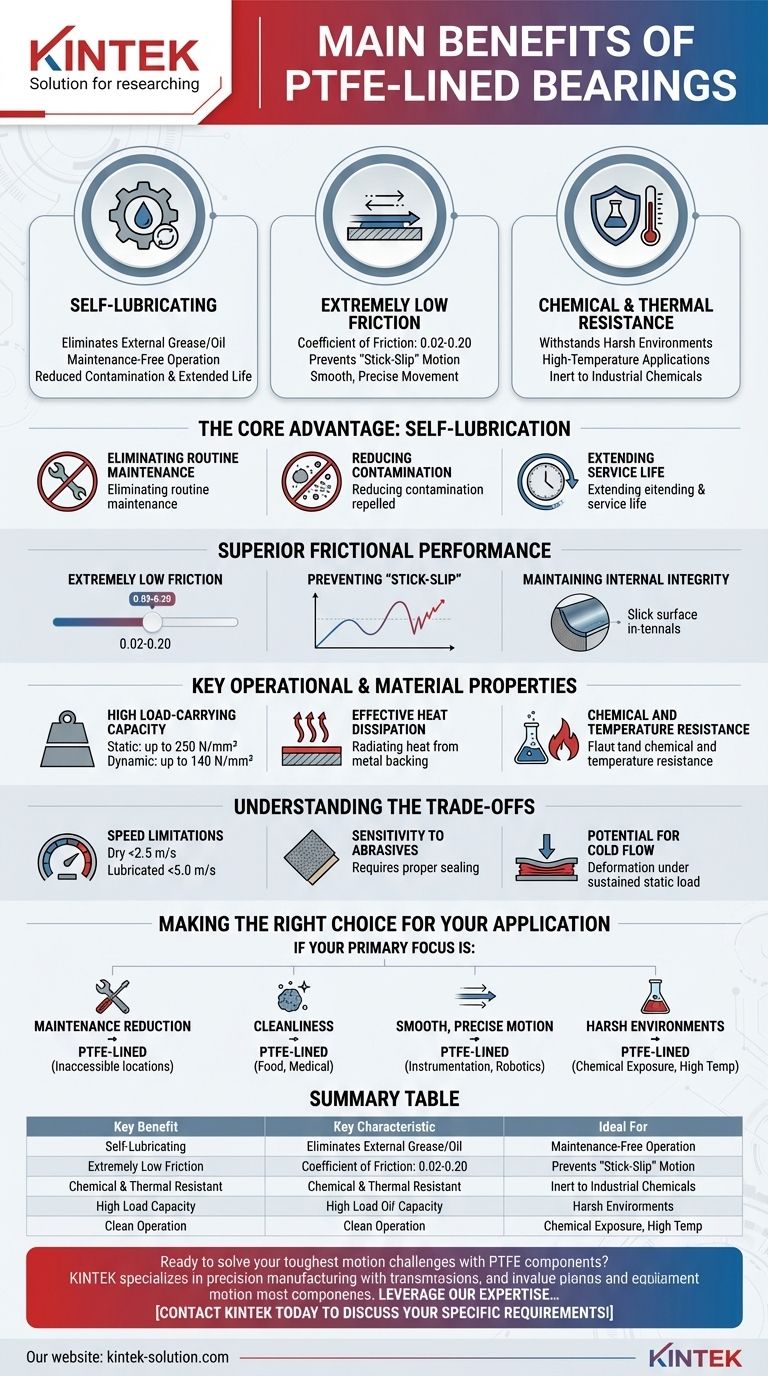

The Core Advantage: Self-Lubrication

The most significant benefit of a PTFE liner is its inherent self-lubricating property. This single feature eliminates the need for external grease or oil, which has several critical downstream effects.

Eliminating Routine Maintenance

Because the bearing lubricates itself, it removes the need for scheduled re-lubrication. This is invaluable for components in remote or inaccessible locations, reducing labor costs and equipment downtime over the life of the machine.

Reducing Contamination

Traditional wet lubricants like grease can attract and trap dirt, dust, and other debris. A dry-running PTFE liner creates a cleaner operating environment, which is essential for industries with strict hygiene standards, such as food processing or medical device manufacturing.

Extending Service Life

The PTFE liner provides a permanent, low-friction layer between the moving metal surfaces. This dramatically reduces wear and tear, preventing galling and seizure and significantly extending the operational lifespan of the bearing and its mating components.

Superior Frictional Performance

PTFE is famous for having one of the lowest coefficients of friction of any solid material. This property is central to the performance of these bearings.

Extremely Low Friction

PTFE-lined bearings have a very low coefficient of friction (typically 0.02-0.20). This minimizes the energy required to initiate and sustain motion, leading to higher mechanical efficiency and smoother operation.

Preventing "Stick-Slip"

The non-stick nature of PTFE prevents the jerky start-stop motion known as stick-slip. This ensures smooth, predictable movement, which is critical for applications requiring high precision and control.

Maintaining Internal Integrity

The slick surface of the liner prevents the buildup of deposits or scaling. This ensures that the bearing's performance remains consistent over time without the risk of internal blockages or increased friction.

Key Operational & Material Properties

Beyond lubrication and friction, the construction of PTFE-lined bearings provides a unique combination of mechanical and environmental resilience.

High Load-Carrying Capacity

While the PTFE liner handles the friction, a steel backing provides the structural strength. This allows the bearing to support high static (up to 250 N/mm²) and dynamic (up to 140 N/mm²) loads.

Effective Heat Dissipation

The metal backing also serves as an excellent conductor of heat. It effectively pulls thermal energy away from the sliding surface, preventing overheating and maintaining operational stability, especially at higher speeds.

Chemical and Temperature Resistance

PTFE is virtually inert to most industrial chemicals and solvents. This, combined with its ability to perform in high-temperature applications, makes these bearings suitable for use in harsh chemical processing or manufacturing environments where traditional lubricants would degrade.

Understanding the Trade-offs

While highly effective, PTFE-lined bearings are not a universal solution. Understanding their operational limits is key to successful implementation.

Speed Limitations

These bearings have defined maximum sliding speeds, typically around 2.5 m/s for dry operation and 5.0 m/s for lubricated conditions. Exceeding these limits can generate excessive heat and accelerate wear.

Sensitivity to Abrasives

The PTFE liner is a relatively soft material. In environments with hard, abrasive particles (like sand or metal filings), the liner can be damaged or worn away quickly, compromising the bearing's performance. Proper sealing is critical in such conditions.

Potential for Cold Flow

Although high-quality liners have good creep resistance, PTFE can be susceptible to "cold flow" or deformation under very high, sustained static loads. This must be considered during the design phase for applications with extreme loading conditions.

Making the Right Choice for Your Application

Selecting the right bearing depends entirely on the primary demands of your design.

- If your primary focus is maintenance reduction: Choose PTFE-lined bearings for inaccessible locations or sealed-for-life units where re-lubrication is not feasible.

- If your primary focus is cleanliness: These bearings are the ideal choice for food, medical, or cleanroom applications where grease contamination is unacceptable.

- If your primary focus is smooth, precise motion: The low, consistent friction of PTFE eliminates stick-slip, making it perfect for instrumentation, robotics, and control linkages.

- If your primary focus is harsh environments: Use these bearings in applications with chemical exposure or high temperatures that would cause traditional lubricants to fail.

By understanding their unique combination of properties, you can leverage PTFE-lined bearings to build more reliable, efficient, and maintenance-free mechanical systems.

Summary Table:

| Key Benefit | Key Characteristic | Ideal For |

|---|---|---|

| Self-Lubricating | Eliminates external grease/oil | Maintenance-free, sealed systems |

| Extremely Low Friction | Coefficient of friction: 0.02-0.20 | Precision motion, high efficiency |

| Chemical & Thermal Resistant | Withstands harsh environments | Chemical processing, high temperatures |

| High Load Capacity | Up to 250 N/mm² static load | Heavy-duty applications |

| Clean Operation | No lubricant contamination | Food, medical, cleanroom industries |

Ready to solve your toughest motion challenges with PTFE components?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bearings, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors by delivering solutions that offer superior chemical resistance, low friction, and maintenance-free operation.

Leverage our expertise in custom fabrication—from prototypes to high-volume orders—to enhance the reliability and efficiency of your equipment. Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does sintering affect the properties of PTFE? Control Crystallinity for Hard or Flexible Parts

- How is Teflon used in cookware? Leveraging Non-Stick Properties for Superior Cooking

- What makes Teflon bushings suitable for harsh environments? Unmatched Chemical & Thermal Resistance

- How are PTFE O-ring seals used in the automotive industry? Critical Sealing Solutions for High-Performance Vehicles

- Why are PTFE rotary shaft seals suitable for the food and beverage industry? Ensure Compliance & Uptime

- How do different glass weave styles affect phase response in RF PCBs? Ensure Phase Coherence for High-Frequency Designs

- What are the properties of 10% PEEK-filled PTFE bushings? Enhance Wear Resistance & High-Temp Performance

- What are the key benefits of Teflon bushes for industrial applications? Reduce Friction and Maintenance