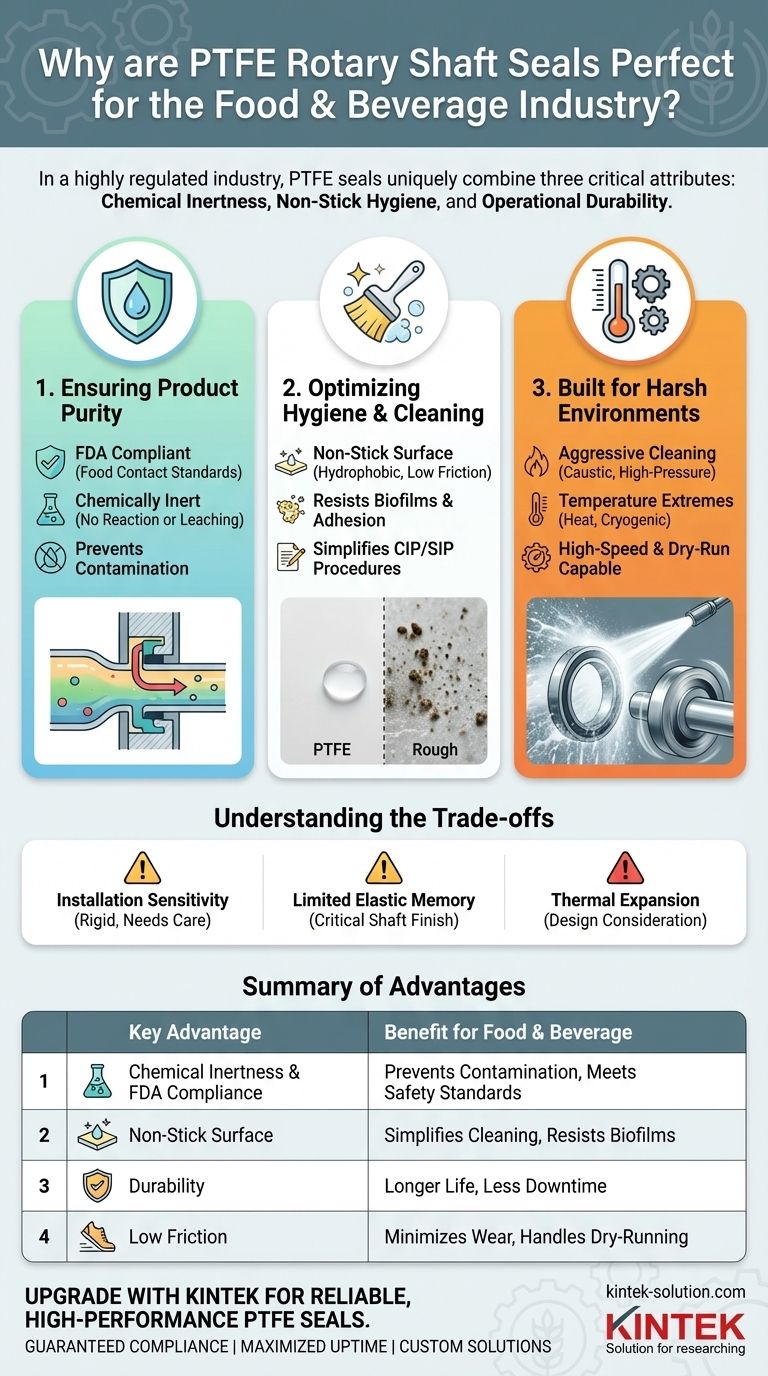

In the highly regulated food and beverage industry, Polytetrafluoroethylene (PTFE) rotary shaft seals are exceptionally suitable because they uniquely combine three critical attributes. They are chemically inert and meet FDA standards for food contact, possess a non-stick surface that resists contamination and simplifies cleaning, and demonstrate the physical durability to withstand aggressive operational environments.

The core challenge in food and beverage processing is balancing stringent hygiene standards with demanding production schedules. PTFE rotary shaft seals are a solution because they are not just components; they are a foundational technology for ensuring both regulatory compliance and operational reliability, preventing contamination while minimizing equipment downtime.

The Foundation: Meeting Strict Regulatory and Hygiene Standards

For a component to be viable in food and beverage applications, its primary qualification is its ability to guarantee product safety and purity. PTFE excels in this non-negotiable requirement.

Ensuring Product Purity with Chemical Inertness

The most critical feature of PTFE is its chemically inert nature. This means the material itself will not react with or leach into food products, even acidic or corrosive ones.

This non-reactive property is the basis for its compliance with stringent regulations, including FDA standards for food-contact materials. Using a PTFE seal ensures that the seal itself is not a source of contamination.

Preventing Microbial Growth with a Non-Stick Surface

PTFE is inherently hydrophobic and has an extremely low coefficient of friction, creating a non-stick surface. In processing equipment like mixers, pumps, and valves, this prevents food particles and microbial biofilms from adhering to the seal.

This characteristic is vital for effective Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures. Because contaminants cannot easily cling to the surface, cleaning cycles are more effective, ensuring a truly hygienic environment and preventing cross-contamination between batches.

Built for the Rigors of Food Production Environments

Beyond safety, a seal must perform reliably under the demanding conditions of modern food processing. PTFE’s physical properties provide a significant operational advantage.

Withstanding Aggressive Cleaning Cycles

Food processing facilities rely on aggressive cleaning agents and high-pressure, high-temperature washdowns to maintain sanitary conditions.

PTFE seals are highly resistant to the caustic chemicals, acids, and disinfectants used in these cleaning cycles. Unlike many elastomeric (rubber) seals that can degrade, swell, or become brittle over time, PTFE maintains its integrity, leading to a longer service life and less frequent replacement.

Performing Under Temperature Extremes

From high-heat cooking and pasteurization to friction-induced heat in high-speed mixers, temperature fluctuation is a constant. PTFE offers excellent thermal stability, performing consistently across a wide range of temperatures.

This allows it to be used in equipment ranging from heated mixers to cryogenic freezing applications without losing its sealing capability or material properties.

Excelling in High-Speed and Dry-Running Conditions

The low-friction nature of PTFE makes it ideal for high-speed rotary applications, such as in industrial blenders or pumps. It generates less frictional heat, which reduces wear on both the seal and the shaft.

Furthermore, this allows for limited dry-running capabilities. In situations where lubrication might fail or is intentionally absent (to prevent product contamination), a PTFE seal can survive for a period without immediate failure, protecting the equipment.

Understanding the Trade-offs of PTFE Seals

While highly effective, PTFE is not a universal solution. Acknowledging its specific characteristics is key to successful implementation.

Installation Sensitivity

PTFE is a more rigid material than traditional elastomers like rubber. This means it has less "give" during installation.

Care must be taken to avoid scratching or nicking the seal lip during assembly, as any damage can create a permanent leak path. Specialized installation tools are often recommended.

Limited Elastic Memory

Unlike rubber, which springs back to its original shape, PTFE has poor elastic memory. If a seal is compressed or a shaft has surface imperfections, PTFE may not conform as effectively over time.

This makes shaft finish and dimensional accuracy more critical when using PTFE seals compared to more forgiving elastomeric alternatives.

Thermal Expansion Considerations

PTFE has a higher rate of thermal expansion than the metals used for shafts and housings. This difference must be accounted for in the design of the seal gland.

Without proper design, a rise in temperature can cause the seal to expand excessively, increasing friction and wear or, in extreme cases, causing the seal to fail.

Making the Right Choice for Your Application

Selecting the right seal requires aligning material properties with your primary operational goal.

- If your primary focus is regulatory compliance and product safety: The FDA-compliant, chemically inert, and non-stick properties of PTFE make it the superior choice for preventing product contamination.

- If your primary focus is operational uptime and reducing maintenance: PTFE's durability and resistance to aggressive cleaning agents and high temperatures translate directly to longer service life and less downtime.

- If you are dealing with high-speed equipment or risk of dry running: The low-friction characteristics of PTFE reduce wear and provide a safety margin that other materials cannot match.

Ultimately, selecting a PTFE rotary shaft seal is a strategic decision to safeguard product integrity and maximize operational reliability.

Summary Table:

| Key Advantage | Benefit for Food & Beverage |

|---|---|

| Chemical Inertness & FDA Compliance | Prevents product contamination, meets strict regulatory standards for food safety. |

| Non-Stick Surface | Resists biofilm & particle adhesion, simplifies Clean-in-Place (CIP) & Sterilize-in-Place (SIP). |

| Durability in Harsh Environments | Withstands aggressive chemicals, high temperatures, and high-speed operation, reducing downtime. |

| Low Friction & Dry-Run Capability | Minimizes wear, handles limited lubrication loss, ideal for mixers and pumps. |

Upgrade your food and beverage equipment with reliable, high-performance PTFE seals from KINTEK.

Our precision-manufactured PTFE components—including custom rotary shaft seals, liners, and labware—are engineered to meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors. For the food and beverage industry, this translates to:

- Guaranteed Regulatory Compliance: Our PTFE materials are FDA-compliant, ensuring your products remain pure and safe.

- Maximized Operational Uptime: Benefit from seals that resist harsh cleaning chemicals and temperature extremes, reducing maintenance frequency.

- Custom Solutions for Your Needs: We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific application.

Protect your products and boost your productivity. Contact KINTEK today for a consultation on your sealing requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions