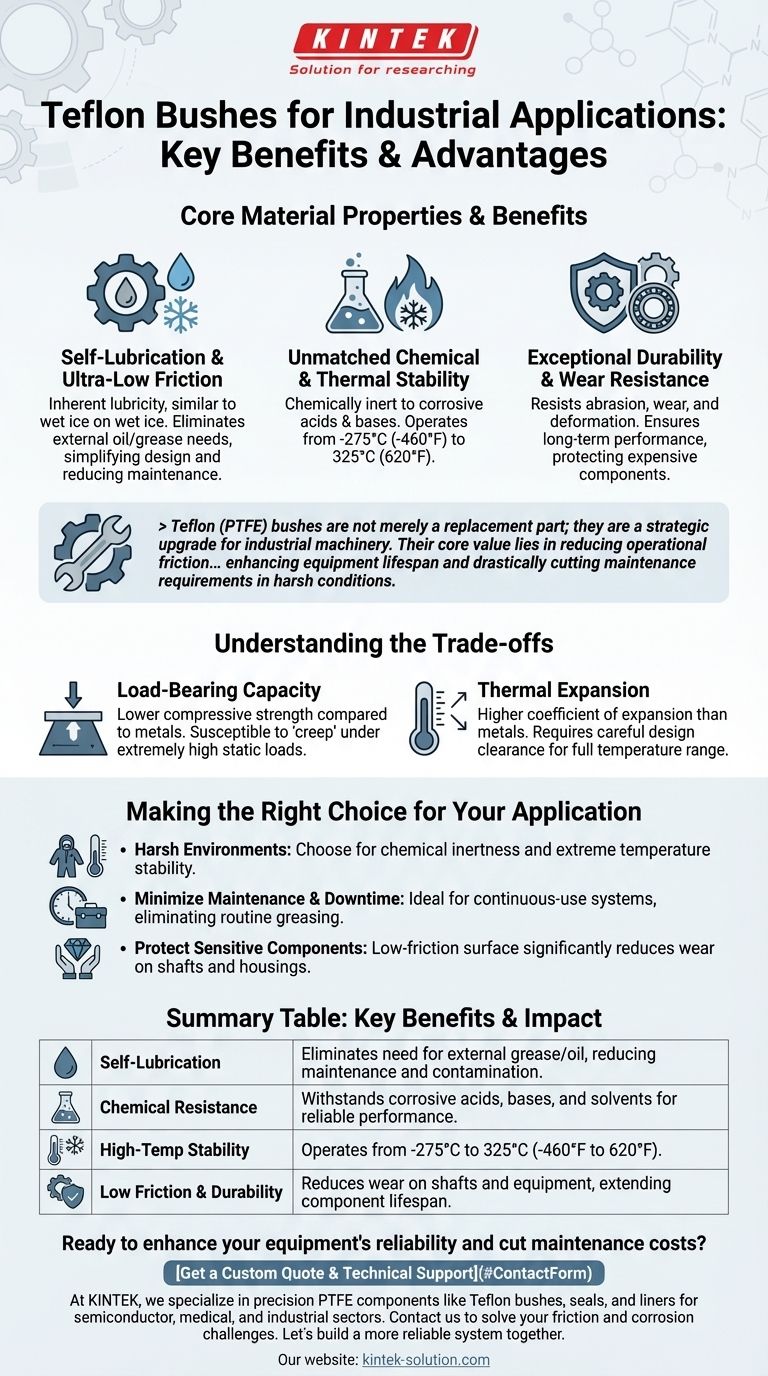

The key benefits of Teflon bushes for industrial applications stem from three core material properties: exceptionally low friction, superior resistance to heat and chemicals, and high durability. This unique combination allows them to reduce mechanical wear, eliminate the need for external lubrication, and operate reliably in environments that would destroy most other materials.

Teflon (PTFE) bushes are not merely a replacement part; they are a strategic upgrade for industrial machinery. Their core value lies in reducing operational friction—both literally and figuratively—by enhancing equipment lifespan and drastically cutting maintenance requirements in harsh conditions.

The Core Advantages Explained

The properties of Teflon translate directly into tangible operational benefits. Understanding these foundational strengths is key to appreciating their impact on system performance and reliability.

Self-Lubrication and Ultra-Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent lubricity means parts move smoothly against the bushing without binding or generating excessive heat.

Crucially, this property is self-lubricating. It completely eliminates the need for oil or grease, which simplifies design, reduces contamination risks, and cuts down on maintenance schedules.

Unmatched Chemical and Thermal Stability

Teflon is chemically inert, meaning it is highly resistant to a vast range of corrosive substances, acids, and bases. This makes it invaluable for applications in chemical processing and other aggressive environments.

It also maintains its integrity across an exceptionally wide temperature range, performing consistently from cryogenic lows of approximately -275°C (-460°F) up to high temperatures of 325°C (620°F).

Exceptional Durability and Wear Resistance

Teflon bushes are highly resistant to abrasion, wear, and deformation. They are engineered to withstand the stresses of constant motion, vibration, and high loads without degrading.

This resilience ensures long-term performance and contributes directly to a longer operational lifespan for the entire mechanical assembly, protecting more expensive components like shafts and housings from damage.

Understanding the Trade-offs

While Teflon's benefits are significant, it is critical to select materials based on the specific demands of the application. An objective assessment includes acknowledging its limitations.

Load-Bearing Capacity

Compared to metallic alternatives like bronze or steel, Teflon generally has a lower compressive strength. In applications with extremely high static loads, the material can be susceptible to "creep," or slow deformation over time.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. This must be accounted for during the design phase to ensure that proper clearances are maintained across the full operational temperature range of the equipment. For most applications, this is a straightforward engineering consideration.

Making the Right Choice for Your Application

Selecting a Teflon bush is an investment in operational resilience. Your primary goal should guide your decision.

- If your primary focus is operating in harsh environments: Teflon's chemical inertness and wide temperature stability make it the definitive choice for applications involving corrosive substances or extreme temperatures.

- If your primary focus is minimizing maintenance and downtime: The self-lubricating nature of Teflon bushes eliminates routine greasing, making them ideal for continuous-use systems or hard-to-access locations.

- If your primary focus is protecting sensitive components: The low-friction, non-abrasive surface significantly reduces wear on shafts and housings, extending the life of your most critical and expensive equipment.

Ultimately, choosing Teflon bushes is a decision to prioritize long-term reliability and reduce the total cost of ownership.

Summary Table:

| Key Benefit | Impact on Your Application |

|---|---|

| Self-Lubrication | Eliminates need for external grease/oil, reducing maintenance and contamination. |

| Chemical Resistance | Withstands corrosive acids, bases, and solvents for reliable performance. |

| High-Temp Stability | Operates from -275°C to 325°C (-460°F to 620°F). |

| Low Friction & Durability | Reduces wear on shafts and equipment, extending component lifespan. |

Ready to enhance your equipment's reliability and cut maintenance costs?

At KINTEK, we specialize in manufacturing precision PTFE components like Teflon bushes, seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your application's demands.

Contact us today to discuss how our Teflon bushes can solve your specific friction and corrosion challenges. Let's build a more reliable and efficient system together.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments