At its core, the suitability of Teflon (PTFE) bushings for harsh environments stems from a unique combination of extreme chemical inertness, a vast operational temperature range, and an inherently low coefficient of friction. These properties allow Teflon to function reliably where metals would corrode, plastics would melt or degrade, and traditional lubricants would fail.

Teflon’s resilience is not just a collection of features; it's a direct result of its stable fluoropolymer structure. This molecular makeup makes it one of the few materials that can simultaneously resist aggressive chemical attack, extreme temperatures, and high friction without external lubrication.

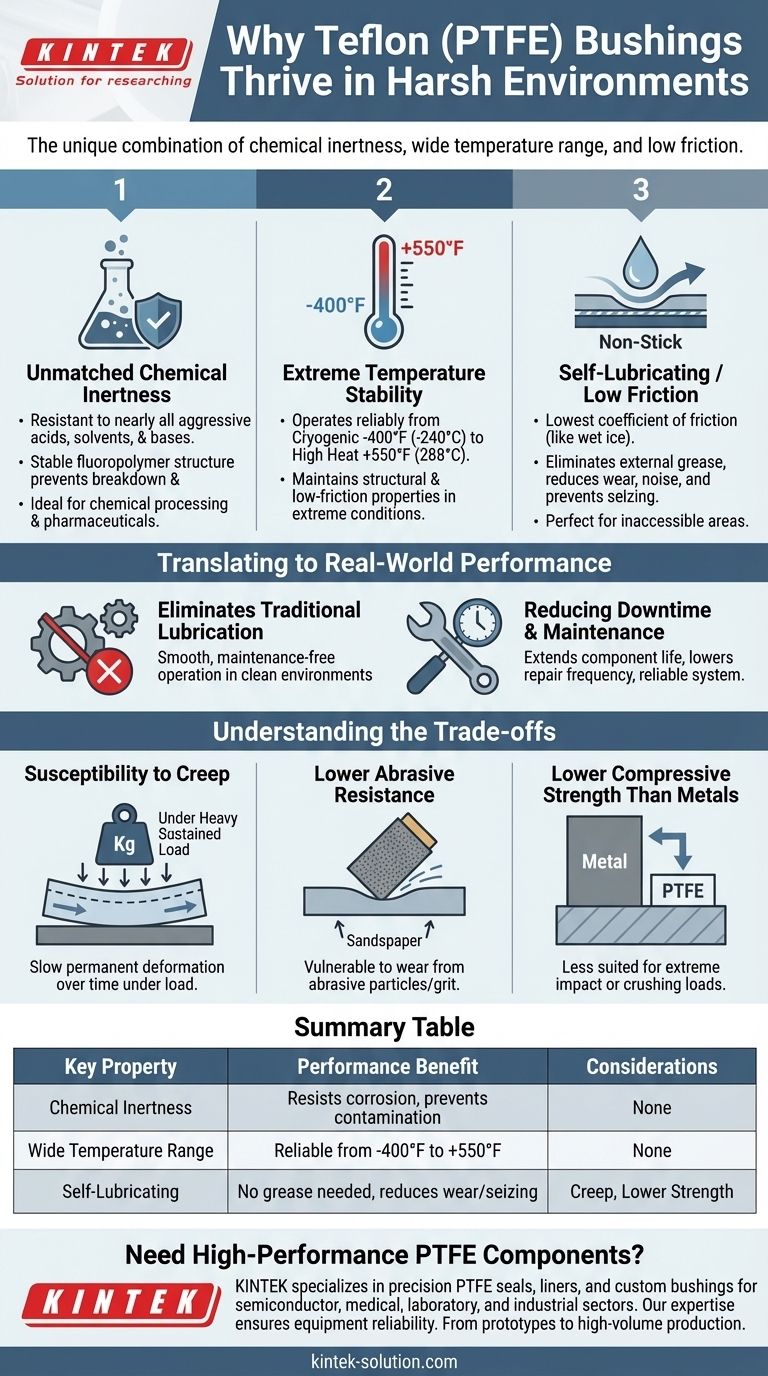

The Core Properties Defining Teflon's Resilience

To understand why Teflon thrives in demanding conditions, we need to examine its three primary characteristics. Each one solves a specific environmental challenge that would compromise or destroy lesser materials.

Unmatched Chemical Inertness

Teflon is exceptionally resistant to nearly all chemicals, including aggressive acids, solvents, and bases. This makes it a default choice for equipment in chemical processing plants, laboratories, and pharmaceutical manufacturing.

Its molecular structure is so stable that very few substances can break it down, with molten alkali metals being a rare exception. This ensures the bushing's integrity and prevents contamination of the process media.

Extreme Temperature Stability

Teflon bushings operate effectively across an incredibly wide thermal spectrum, from cryogenic lows of -400°F (-240°C) to high-heat applications up to +550°F (288°C).

This allows them to be used in everything from deep-freeze systems to industrial ovens and engines, maintaining their structural and low-friction properties at temperatures that would cause other materials to become brittle or deform.

Self-Lubricating and Low Friction

The material has one of the lowest coefficients of friction of any solid, often compared to wet ice on wet ice. This self-lubricating or "non-stick" quality is critical in harsh environments where applying external grease or oil is impractical or impossible.

This characteristic reduces wear on moving parts, lowers operational noise, and prevents the seizing of components, which is vital for high-load, high-speed, or continuous-use machinery.

How These Properties Translate to Real-World Performance

The theoretical advantages of Teflon directly lead to tangible benefits in industrial and technical applications, enhancing equipment reliability and reducing operational costs.

Eliminating Traditional Lubrication

In environments where contaminants are a concern (like food processing) or where lubrication is difficult to apply, Teflon's self-lubricating nature is a significant advantage. It provides smooth, maintenance-free operation for extended periods.

Reducing Downtime and Maintenance

By resisting chemical degradation, thermal damage, and mechanical wear, Teflon bushings extend the life of critical components. This directly translates to less frequent downtime for repairs and a more reliable system overall.

Enabling Operation in a Vacuum

Because Teflon does not "outgas" (release trapped gasses) like many other plastics and requires no liquid lubricant that would evaporate, it is also suitable for use in vacuum environments, a uniquely harsh condition.

Understanding the Trade-offs

While incredibly capable, Teflon is not universally superior. As a trusted advisor, it's my responsibility to clarify its limitations. The primary trade-off comes from the fact that it is a relatively soft polymer.

Susceptibility to Creep

Under a heavy, sustained load, Teflon can be subject to "creep," which is a slow, permanent deformation over time. This is more pronounced at the higher end of its temperature range. For extremely high static loads, a filled PTFE or a different material might be necessary.

Lower Abrasive Resistance

Teflon’s low-friction surface is excellent for smooth, sliding contact but can be vulnerable to wear from hard, abrasive particles. In environments with significant grit, sand, or other abrasive contaminants, the bushing may wear more quickly than a hardened metal equivalent unless properly sealed.

Lower Compressive Strength Than Metals

While its compressive strength is high for a polymer, it is significantly lower than that of metals like steel or bronze. In applications where the bushing must withstand extreme impact loads or crushing forces, a metallic bearing may be a more appropriate choice.

Making the Right Choice for Your Application

Selecting the right bushing material requires aligning its properties with your primary operational challenge.

- If your primary focus is chemical resistance: Teflon is almost certainly the best choice, offering near-universal inertness that protects both your equipment and your process.

- If your primary focus is a wide temperature range: Teflon's stability from cryogenic lows to high heat makes it one of the most versatile options available.

- If your primary focus is maintenance-free, self-lubricated operation: Teflon excels in applications where external lubrication is undesirable or impossible, reducing friction and wear over the long term.

- If your primary focus is withstanding extreme static loads or abrasive particles: You should carefully evaluate if Teflon's compressive strength and abrasion resistance are sufficient for your specific needs or if a composite or metallic solution is required.

Ultimately, choosing Teflon is a strategic decision to prioritize chemical and thermal stability in environments where conventional materials simply cannot survive.

Summary Table:

| Key Property | Performance Benefit in Harsh Environments |

|---|---|

| Chemical Inertness | Resists nearly all acids, solvents, and bases; prevents corrosion and contamination. |

| Wide Temperature Range | Functions reliably from -400°F (-240°C) to +550°F (288°C). |

| Self-Lubricating / Low Friction | Eliminates need for external grease; reduces wear and prevents seizing. |

| Considerations | Lower compressive strength than metals; susceptible to creep under heavy, sustained loads. |

Need high-performance PTFE components for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components like seals, liners, and custom bushings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from Teflon's superior chemical resistance and thermal stability, enhancing reliability and reducing maintenance.

Let us provide the right solution for your harsh environment—from prototypes to high-volume production.

Contact KINTEK today for a consultation on your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How is PTFE applied in electronics and semiconductor manufacturing? Ensure Purity and Performance

- What challenges arise during the manufacturing of skived PTFE sheets? Achieving Consistent Quality and Performance

- What customization options are available for PTFE rotary shaft seals? Tailor for High Performance

- What makes Teflon plastic sheets versatile across industries? The Ultimate High-Performance Solution

- What are the advantages of PTFE/PFA lining in steel pipes? Achieve Superior Corrosion Resistance and Purity

- What issue can arise when PTFE gaskets are subjected to external pressure? Prevent Seal Failure and Deformation

- What are the main advantages of using PTFE oil seals? Superior Performance for Extreme Conditions

- Which acids show high resistance with Teflon FEP and PFA encapsulated O-rings? Ensure Leak-Free Performance in Aggressive Chemical Environments