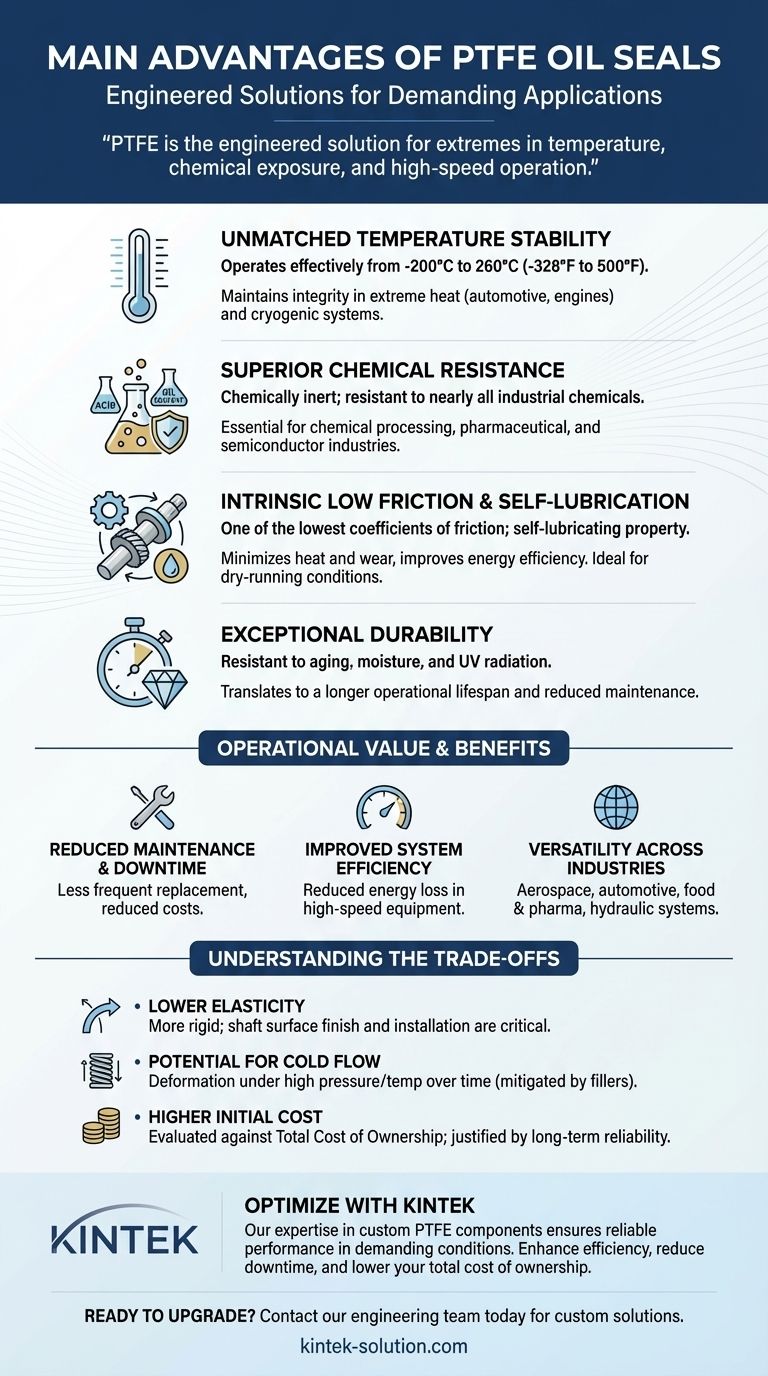

At their core, PTFE oil seals offer a superior performance profile for demanding applications where traditional elastomer seals would fail. Their primary advantages are an exceptionally wide operating temperature range, near-universal chemical resistance, and an inherently low coefficient of friction that reduces wear and energy consumption.

The decision to use a PTFE seal is a decision to prioritize long-term reliability in harsh environments. While traditional seals may suffice for standard conditions, PTFE is the engineered solution for extremes in temperature, chemical exposure, and high-speed operation.

The Core Engineering Advantages of PTFE Seals

The unique molecular structure of Polytetrafluoroethylene (PTFE) gives it several distinct properties that make it an ideal material for high-performance sealing.

Unmatched Temperature Stability

PTFE seals operate effectively across an exceptionally broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This allows them to maintain their integrity and sealing capability in applications involving extreme heat, such as automotive turbochargers and high-performance engines, as well as in cryogenic systems.

Superior Chemical Resistance

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals, including aggressive acids, solvents, oils, and process fluids.

Unlike elastomeric seals that can swell, degrade, or harden when exposed to certain chemicals, PTFE maintains its form and function. This makes it essential for the chemical processing, pharmaceutical, and semiconductor industries.

Intrinsic Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property significantly reduces rotational drag on the shaft.

The benefits are twofold: it minimizes heat generation and wear on both the seal and the shaft, and it improves overall mechanical efficiency by reducing energy loss. This also allows PTFE seals to perform reliably in dry-running or minimally lubricated conditions where other seals would quickly fail.

Exceptional Durability

The combination of thermal stability and chemical resistance makes PTFE highly durable. It is also resistant to environmental factors like moisture and UV radiation.

This inherent toughness translates to a longer operational lifespan, resisting the aging and degradation that commonly affect other sealing materials over time.

Translating Properties into Operational Value

These engineering characteristics provide tangible benefits in terms of cost, efficiency, and system reliability.

Reduced Maintenance and Downtime

The exceptional durability of PTFE seals means they require less frequent replacement.

For any operation, this leads directly to reduced maintenance costs, less consumption of spare parts, and most importantly, minimized system downtime.

Improved System Efficiency

The low-friction nature of PTFE seals reduces the energy required to turn a shaft. In high-speed equipment, this can lead to measurable gains in energy efficiency and performance.

Versatility Across Demanding Industries

The robust properties of PTFE allow these seals to be specified in a wide range of critical applications.

They are a standard component in aerospace and automotive (transmissions, engines), chemical processing equipment, food and pharmaceutical manufacturing (where hygiene and non-reactivity are key), and high-pressure hydraulic systems.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized component, and it's important to understand their specific characteristics compared to traditional rubber seals.

Lower Elasticity

PTFE is a much more rigid material than elastomers like Nitrile (NBR) or Viton (FKM). It does not have the same "rubbery" memory.

This means that shaft surface finish and installation precision are more critical. A PTFE seal is less forgiving of shaft imperfections or minor installation errors compared to a more compliant rubber seal.

Potential for Cold Flow

Under a combination of high pressure and temperature, PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time.

Seal manufacturers mitigate this by adding fillers (like glass, carbon, or graphite) to the PTFE compound, but it remains a design consideration for very high-pressure applications.

Higher Initial Cost

As a high-performance engineered material, PTFE seals typically have a higher upfront cost than standard elastomeric seals.

This cost should be evaluated against the total cost of ownership. The investment is often justified by reduced maintenance, longer life, and greater system reliability, especially in critical applications where failure is not an option.

Making the Right Choice for Your Application

Selecting the correct seal material depends entirely on the operational demands of your system.

- If your primary focus is extreme temperatures or aggressive chemicals: PTFE is almost certainly the correct choice, as standard elastomers will quickly degrade.

- If your primary focus is maximizing efficiency in high-speed equipment: PTFE's low-friction properties will reduce drag and wear, making it a superior option.

- If your primary focus is minimizing total cost of ownership in a critical system: The longevity and reliability of a PTFE seal often justify its higher initial price by preventing costly downtime.

- If your primary focus is a standard, cost-sensitive application with moderate conditions: A traditional elastomeric seal may provide sufficient performance at a lower upfront cost.

Ultimately, choosing a PTFE seal is an investment in stability and performance for applications that operate beyond conventional limits.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Temperature Stability | Operates from -200°C to 260°C | Extreme heat/cold applications |

| Chemical Resistance | Inert to nearly all industrial chemicals | Chemical processing, pharmaceuticals |

| Low Friction | Self-lubricating, reduces energy loss | High-speed equipment, dry-running conditions |

| Durability | Resists aging, moisture, and UV radiation | Long-life, reduced maintenance cycles |

Optimize your sealing solutions with KINTEK's precision PTFE components.

Our expertise in custom fabricating PTFE seals, liners, and labware ensures your equipment performs reliably in the most demanding conditions—from semiconductor manufacturing to medical and industrial applications. We deliver superior chemical resistance, thermal stability, and low friction to enhance efficiency, reduce downtime, and lower your total cost of ownership.

Ready to upgrade to a seal built for extremes? Contact our engineering team today to discuss your custom PTFE requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions