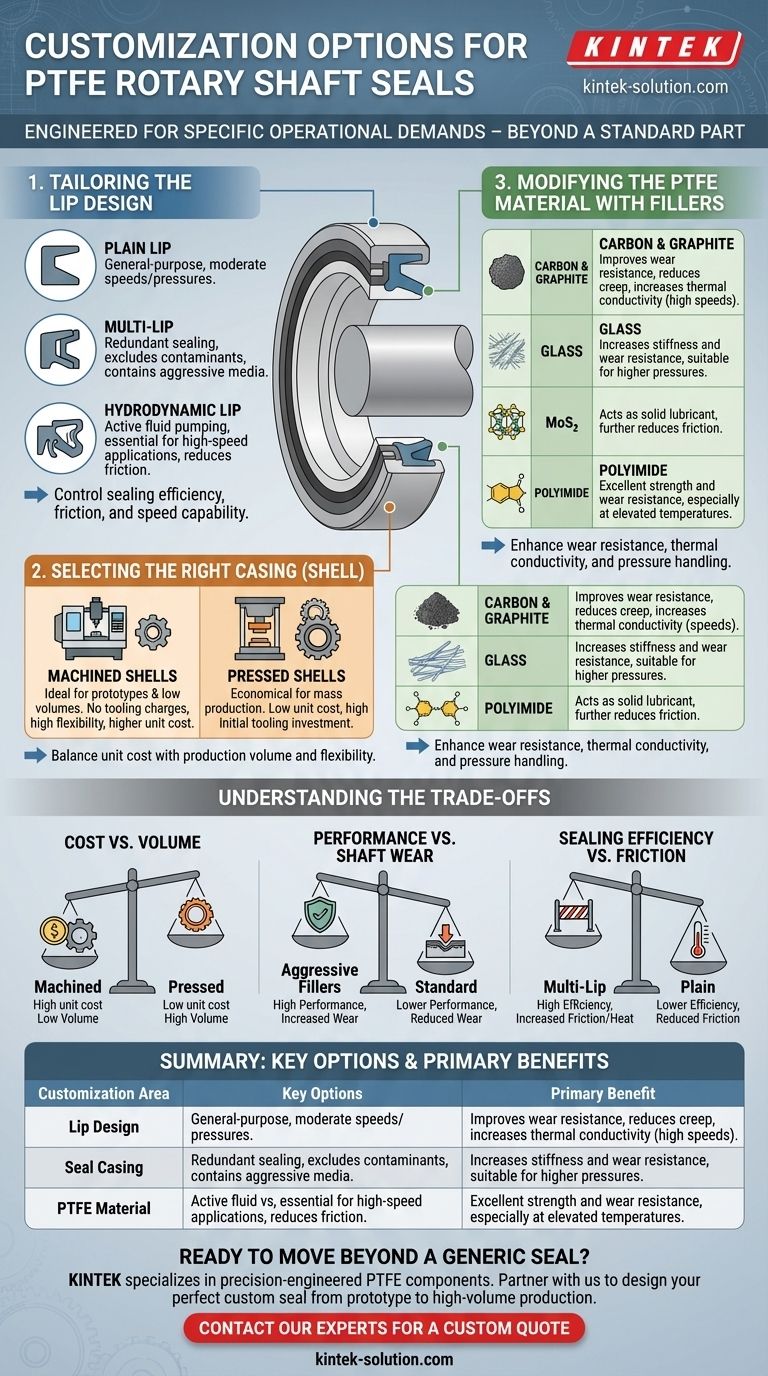

Beyond a standard part number, PTFE rotary shaft seals are highly adaptable components that can be engineered for specific operational demands. The primary customization options revolve around three core areas: the lip design (plain, multi-lip, or hydrodynamic), the seal casing (machined for low volumes or pressed for high volumes), and the PTFE material composition itself, which can be modified with fillers like carbon, glass, or MoS2.

The fundamental challenge is that a generic seal is a compromise. Customization allows you to move beyond this compromise by precisely tailoring the seal's material properties and mechanical design to master specific environmental challenges like high speeds, extreme pressures, or aggressive chemical exposure.

The Core Components of Customization

Understanding your options begins with breaking the seal down into its key customizable elements. Each element directly influences how the seal will perform under load, speed, and environmental stress.

Tailoring the Lip Design

The seal lip is the primary point of contact with the rotating shaft, and its geometry is critical.

- Plain Lip: This is a standard, straightforward design suitable for general-purpose applications with moderate speeds and pressures.

- Multi-Lip: Featuring two or more lips, this configuration provides redundant sealing points, which is beneficial for containing aggressive media or excluding external contaminants.

- Hydrodynamic Lip: This advanced design incorporates features that actively pump fluid back towards the system's interior during rotation. It is essential for high-speed applications where it prevents fluid leakage and reduces friction.

Selecting the Right Casing (Shell)

The metal casing provides structural integrity and facilitates installation. The manufacturing method is a key decision driven by production volume.

- Machined Shells: These are manufactured without dedicated tooling, making them ideal for prototypes, small production runs, or custom sizes. This approach avoids high upfront tooling charges.

- Pressed Shells: For high-volume production, shells are stamped or "pressed" using dedicated tooling. While there is an initial investment, the cost per unit is significantly lower, making it the economical choice for mass production.

Modifying the PTFE Material with Fillers

While pure PTFE has excellent chemical resistance and a low friction coefficient, its mechanical properties can be significantly enhanced by adding fillers.

- Carbon and Graphite: These fillers improve wear resistance, reduce creep (deformation under load), and increase thermal conductivity, helping to dissipate heat in high-speed applications.

- Glass: Adding glass fibers significantly increases the seal's stiffness and wear resistance, making it suitable for higher pressure applications.

- MoS₂ (Molybdenum Disulfide): Often used in conjunction with other fillers, MoS₂ acts as a solid lubricant, further reducing the seal's coefficient of friction.

- Polyimide: This filler offers excellent strength and wear resistance, particularly at elevated temperatures.

Understanding the Trade-offs

Customization is a process of balancing competing priorities. There is no single "best" seal, only the best seal for a specific set of operating conditions.

Cost vs. Volume

The most apparent trade-off is between machined and pressed shells. Machined casings offer flexibility and avoid tooling costs, but carry a higher price per unit. Pressed casings are the opposite, requiring a significant initial investment but delivering a very low unit cost at scale.

Performance vs. Shaft Wear

Aggressive fillers that enhance seal durability, such as glass, can increase the wear rate on the mating shaft surface. This trade-off can be mitigated by ensuring proper shaft hardness and surface finish or by using a precision-ground running sleeve to provide an ideal, replaceable mating surface.

Sealing Efficiency vs. Friction

A multi-lip design creates a more robust sealing barrier but also increases the contact area with the shaft. This can lead to higher running friction and heat generation compared to a simpler single-lip configuration, which must be accounted for in the system's thermal management.

Making the Right Choice for Your Application

Selecting the right combination of features requires a clear understanding of your primary operational goal.

- If your primary focus is high rotational speed: Prioritize a hydrodynamic lip design to manage lubrication and prevent leakage, combined with a carbon/graphite-filled PTFE for superior thermal dissipation.

- If your primary focus is high-pressure sealing: Choose a robust lip profile and a PTFE compound filled with glass or polyimide to provide the necessary rigidity and prevent extrusion.

- If your primary focus is chemical compatibility: Start with the inherent resistance of PTFE and select a filler that is also inert to your specific media.

- If your primary focus is cost-efficiency for mass production: A pressed shell casing is the clear choice, paired with the most economical PTFE compound that meets your minimum performance requirements.

- If your primary focus is prototyping or low-volume production: Specify a machined shell casing to maintain design flexibility and avoid high upfront tooling investments.

Ultimately, customizing a PTFE rotary shaft seal is the key to transforming it from a simple component into a high-performance solution engineered for system reliability.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Lip Design | Plain, Multi-lip, Hydrodynamic | Control sealing efficiency, friction, and speed capability |

| Seal Casing | Machined (low volume), Pressed (high volume) | Balance unit cost with production volume and flexibility |

| PTFE Material | Carbon, Glass, MoS₂, Polyimide fillers | Enhance wear resistance, thermal conductivity, and pressure handling |

Ready to move beyond a generic seal?

At KINTEK, we specialize in precision-engineered PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We partner with you to design and fabricate the perfect custom PTFE rotary shaft seal—from prototype to high-volume production—ensuring it is tailored to master your specific challenges with speed, pressure, and aggressive chemicals.

Contact our experts today to discuss your application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is dimensional stability important for PTFE rod in heavy-load applications? Prevent Failure & Ensure Reliability

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments

- What are the main types of PTFE lined valves? Find the Right Valve for Your Corrosive Application

- What are the long-term cost benefits of using PTFE expansion bellows? Invest in Durability to Slash Downtime & Maintenance Costs

- What economic advantages do ePTFE gaskets offer? Lower Total Cost of Ownership

- What are the key properties and applications of PEEK material? Unmatched Performance for Extreme Environments

- What modifications can be made to a PTFE seal to handle slight shaft runout? Compensate for Dynamic Movement

- What are PTFE Bellows and what material are they made from? Discover the Key to Chemical Resistance & Flexibility