In short, PTFE O-Rings offer superior performance over standard elastomers in extreme conditions. Their primary advantages stem from near-universal chemical resistance, an exceptionally wide operating temperature range, and an almost unlimited shelf life due to their immunity to aging factors like UV light and moisture.

The core takeaway is not that PTFE is universally "better" than elastomers, but that it is a specialized engineering plastic designed for sealing applications where common rubber compounds would quickly degrade and fail due to aggressive chemicals, cryogenic temperatures, or high heat.

Unmatched Resilience in Extreme Environments

The fundamental value of Polytetrafluoroethylene (PTFE) lies in its molecular stability. This stability translates directly into performance advantages in demanding industrial, chemical, and aerospace applications.

Near-Universal Chemical Inertness

PTFE is impervious to almost all industrial chemicals, including aggressive acids, solvents, and bases. This makes it an ideal choice for systems handling corrosive materials.

Unlike elastomers, which have specific chemical compatibility charts and can swell or degrade on contact with the wrong media, PTFE provides a reliable seal across a vast spectrum of substances.

Exceptional Thermal Stability

PTFE O-rings function effectively across an enormous temperature range, typically from -325°F to +500°F (-200°C to +260°C).

This allows them to be used in cryogenic applications where standard rubbers would become brittle and crack, as well as in high-heat environments where elastomers would soften, melt, or permanently deform.

Superior Long-Term Performance and Stability

Beyond its resistance to harsh conditions, PTFE exhibits properties that ensure reliability and a long service life, reducing maintenance and failure risks.

Immunity to Aging and Environmental Factors

PTFE does not degrade with age and is unaffected by UV radiation. This gives it a virtually unlimited shelf life, a significant advantage over elastomers that can dry out and crack over time.

Dimensional Stability and Low Swell

Because PTFE is hydrophobic, it does not absorb moisture. This prevents the material from swelling, a common failure mode for elastomeric seals that can lead to increased friction, wear, and seal extrusion.

Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick characteristic is critical for dynamic applications like rotary seals, as it reduces drag, heat generation, and wear on moving parts.

Excellent Electrical Insulation

The material also possesses excellent dielectric properties, making it a superb electrical insulator. This is a valuable secondary benefit in applications where electrical isolation is required.

Understanding the Trade-offs

While its advantages are significant, PTFE is not a drop-in replacement for elastomers in every situation. Its plastic nature introduces critical trade-offs that must be considered.

Reduced Elasticity and Memory

PTFE is a rigid plastic, not a flexible rubber. It has poor elastic memory, meaning it does not spring back to its original shape as effectively as an elastomer after being compressed. This can make achieving a perfect seal in standard O-ring grooves more challenging.

Susceptibility to Cold Flow (Creep)

Under sustained pressure, especially at elevated temperatures, PTFE can be prone to "creep" or "cold flow". This is a slow, permanent deformation of the material that can eventually lead to a loss of sealing force.

Higher Seating Force Requirement

Due to its rigidity, a PTFE O-ring often requires more initial compression (squeeze) than an elastomeric O-ring to create an effective seal, which may influence the design of the housing or gland.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching its properties to the demands of the operating environment.

- If your primary focus is aggressive chemical resistance: PTFE is the definitive choice, offering near-universal compatibility where most elastomers would fail.

- If your application involves extreme temperatures (high or low): PTFE's vast operating range makes it one of the few viable options.

- If you need a reliable, low-pressure static seal in a standard environment: A common elastomer like NBR or Viton is often more cost-effective and its elasticity is better suited for the task.

- If you need both chemical resistance and good elasticity: Consider a PTFE encapsulated O-ring, which combines a flexible elastomeric core with a seamless outer PTFE jacket.

Ultimately, choosing PTFE is a decision to prioritize chemical and thermal resilience for applications that push beyond the limits of conventional materials.

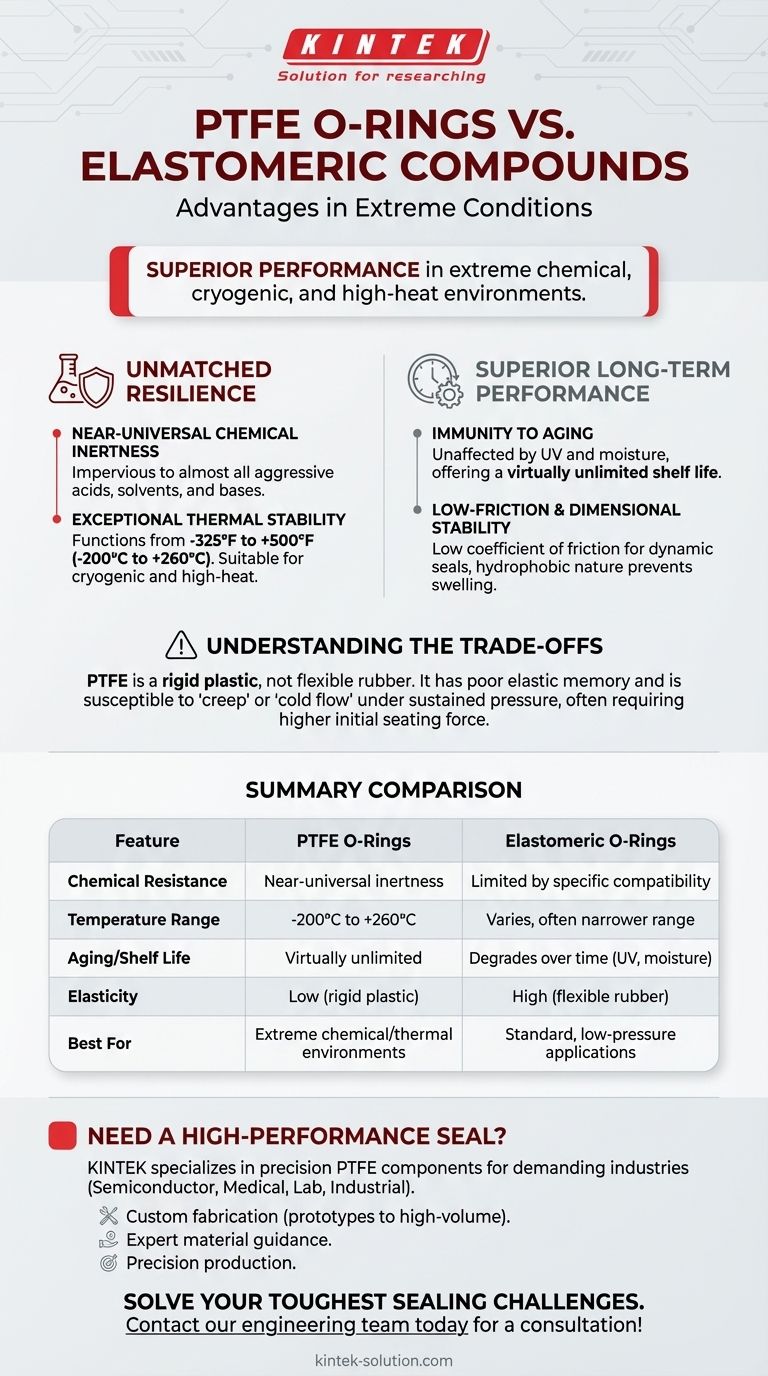

Summary Table:

| Feature | PTFE O-Rings | Elastomeric O-Rings |

|---|---|---|

| Chemical Resistance | Near-universal inertness | Limited by specific compatibility |

| Temperature Range | -200°C to +260°C | Varies, often narrower range |

| Aging/Shelf Life | Virtually unlimited | Degrades over time (UV, moisture) |

| Elasticity | Low (rigid plastic) | High (flexible rubber) |

| Best For | Extreme chemical/thermal environments | Standard, low-pressure applications |

Need a High-Performance Seal for Demanding Conditions?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for industries where failure is not an option. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a sealing solution that withstands aggressive chemicals, extreme temperatures, and long-term use.

We offer:

- Custom fabrication from prototypes to high-volume orders.

- Expert guidance on material selection for your specific application.

- Precision production to meet the most demanding specifications.

Let us help you solve your toughest sealing challenges. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries commonly use PTFE-encapsulated O-rings? Ensure Reliability in Demanding Applications

- What are the main disadvantages of pure PTFE? Understand Its Critical Limitations for Your Application

- What is a PTFE lined butterfly valve and how does it work? Control Corrosive & Pure Fluids Safely

- When are split PTFE backup rings particularly suitable? Ideal for Retrofitting and High-Pressure Seals

- What are the primary advantages of Teflon washers compared to metal washers? Unlock Superior Performance in Harsh Environments

- How does PTFE's coefficient of friction compare to other materials? Discover the Slipperiest Solid

- What is the preferred composition for PTFE wear resistant material and why? Achieve Superior Performance with Bronze-Filled PTFE

- What are the key properties of PTFE and EPDM that influence their use in butterfly valves? Choose the Right Valve Seat Material