The primary advantages of Teflon washers over their metal counterparts are their exceptional low friction, inherent resistance to chemicals and corrosion, and effective electrical insulation. This unique combination of properties allows them to succeed in dynamic, harsh, or electrically sensitive environments where metal washers would quickly fail.

While metal washers are unmatched for high compressive strength, Teflon (PTFE) washers solve a different set of problems. Their core advantage lies not in brute force, but in a unique blend of chemical inertness and an extremely low coefficient of friction, ensuring smooth operation and long-term reliability.

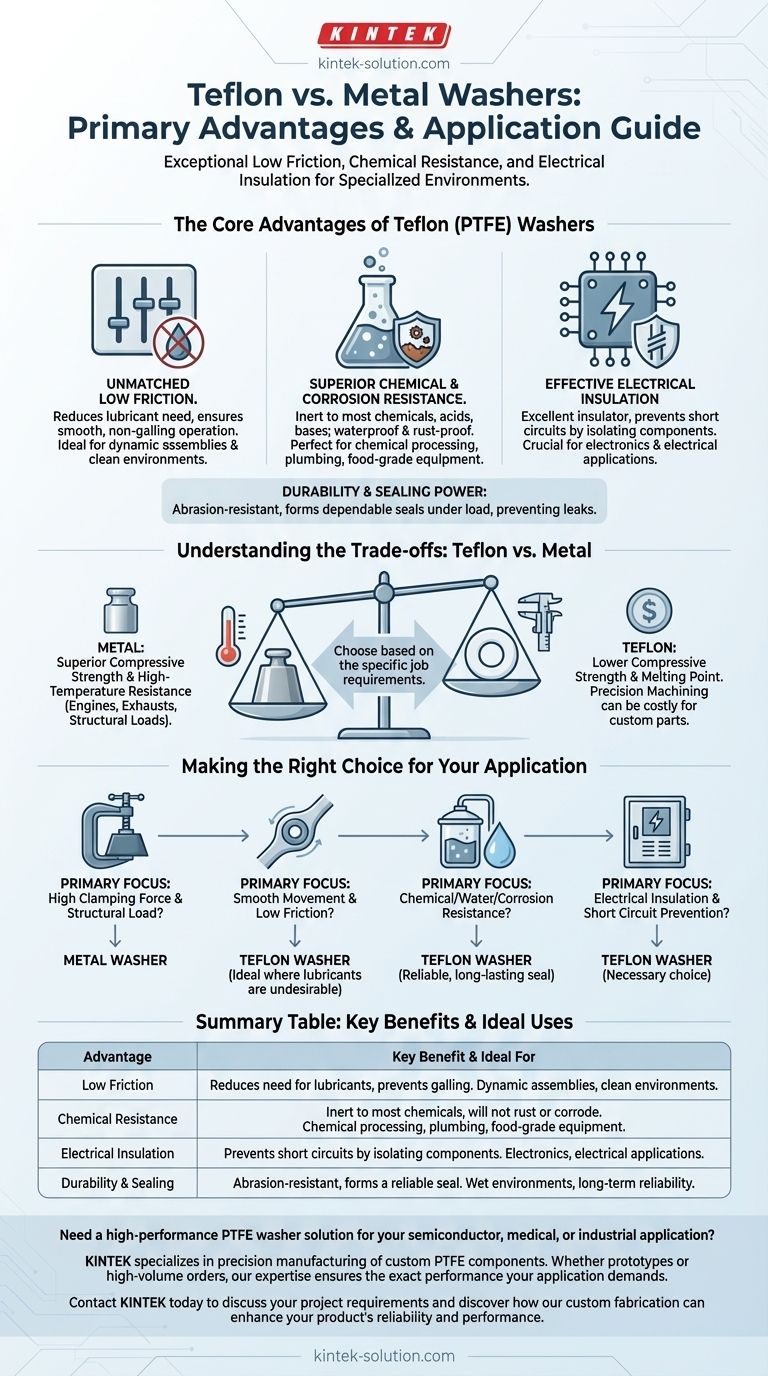

The Core Advantages of Teflon (PTFE) Washers

Polytetrafluoroethylene (PTFE), the material known as Teflon, possesses a distinct set of characteristics that make it a superior choice for specific mechanical and industrial applications.

Unmatched Low Friction

Teflon is one of the most slippery materials known, giving it a naturally low coefficient of friction.

This property reduces the need for external lubricants like grease or oil, making Teflon washers ideal for clean environments or field use where re-lubrication is impractical.

In assemblies with moving parts, such as knife pivots, this slipperiness ensures smooth, non-galling operation and significantly reduces wear on adjacent metal surfaces.

Superior Chemical and Corrosion Resistance

Unlike most metals, Teflon is chemically inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This makes it an essential component in chemical processing, plumbing, and food-grade equipment where contamination or material degradation is a critical concern.

Furthermore, Teflon is completely waterproof and will not rust or corrode, guaranteeing a long-lasting and reliable seal in wet or outdoor environments.

Effective Electrical Insulation

Metal is a conductor of electricity, while Teflon is an excellent electrical insulator.

This distinction is crucial in electronics and electrical applications. Teflon washers are used to isolate fasteners like screws and bolts from conductive chassis, preventing short circuits.

Durability and Sealing Power

Despite being a polymer, high-quality PTFE is durable, abrasion-resistant, and not easily compressed.

This allows it to form a tight, dependable seal under appropriate loads, preventing leaks without deforming or creeping over time in a way that softer materials might.

Understanding the Trade-offs: Teflon vs. Metal

Choosing between Teflon and metal is not about which is "better" overall, but which is correct for the specific job. Understanding their limitations is key to making the right decision.

Compressive Strength and Load Bearing

For applications requiring immense clamping force or supporting heavy structural loads, hardened steel washers are vastly superior.

Teflon washers are not designed for the extreme compressive stress that metal can withstand and can deform under excessive bolt torque.

High-Temperature Limitations

While Teflon has good temperature stability across a wide range, especially in cold environments, it has a much lower melting point than metal.

In high-temperature applications like engines or exhaust systems, metal washers are the only viable option.

Precision and Cost

Standard Teflon washers are readily available and affordable. However, creating a highly precise washer with tight tolerances often requires machining.

Depending on the specifications, a custom-machined Teflon part can be more costly than a simple stamped metal washer.

Making the Right Choice for Your Application

Your final decision should be dictated by the primary demands of your project's environment and performance goals.

- If your primary focus is high clamping force and structural load: A high-strength metal washer is the correct choice.

- If your primary focus is smooth movement and low friction: Teflon is the ideal solution, especially where lubricants are undesirable or impractical.

- If your primary focus is resistance to chemicals, water, or corrosion: Teflon provides a far more reliable and long-lasting seal than most common metals.

- If your primary focus is electrical insulation: Teflon is the necessary choice to prevent electrical conductivity and short circuits.

By understanding these fundamental differences, you can select the right washer based on the precise performance your application demands.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Friction | Reduces need for lubricants, prevents galling | Dynamic assemblies, clean environments |

| Chemical Resistance | Inert to most chemicals, will not rust or corrode | Chemical processing, plumbing, food-grade equipment |

| Electrical Insulation | Prevents short circuits by isolating components | Electronics, electrical applications |

| Durability & Sealing | Abrasion-resistant, forms a reliable seal | Wet environments, long-term reliability |

Need a high-performance PTFE washer solution for your semiconductor, medical, or industrial application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We understand the critical demands of harsh and specialized environments. Whether you require prototypes or high-volume orders, our expertise ensures you get the exact performance your application demands.

Contact KINTEK today to discuss your project requirements and discover how our custom fabrication can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How do you select the right PTFE gasket for an application? A Guide to Matching Material to Your Demands

- What are the primary properties of PTFE rod? Unlock Extreme Performance for Demanding Applications

- What types of fluids can PTFE control valves handle? Master Corrosive Chemicals with Confidence

- What advantages do Teflon O-rings offer compared to other materials? Unmatched Chemical & Thermal Resistance

- What is the tensile strength of Teflon balls? Leverage Its Unique Properties for Your Application

- Why is professional consultation recommended for custom seal solutions? Mitigate Risk and Ensure Operational Integrity

- What are the key benefits of using PTFE lined valves in chemical plants? Boost Safety and Cut Costs

- What are some application examples of PTFE O-ring seals in mechanical equipment? Solve Extreme Sealing Challenges