In short, PTFE-encapsulated O-rings are predominantly used in industries where seals face aggressive chemicals, extreme temperatures, or stringent purity requirements. The most common sectors include chemical processing, medical and pharmaceutical manufacturing, semiconductor fabrication, food and beverage, aerospace, and power generation. These O-rings solve the critical challenge of needing both the chemical inertness of PTFE and the flexible, reliable sealing pressure of a traditional rubber O-ring.

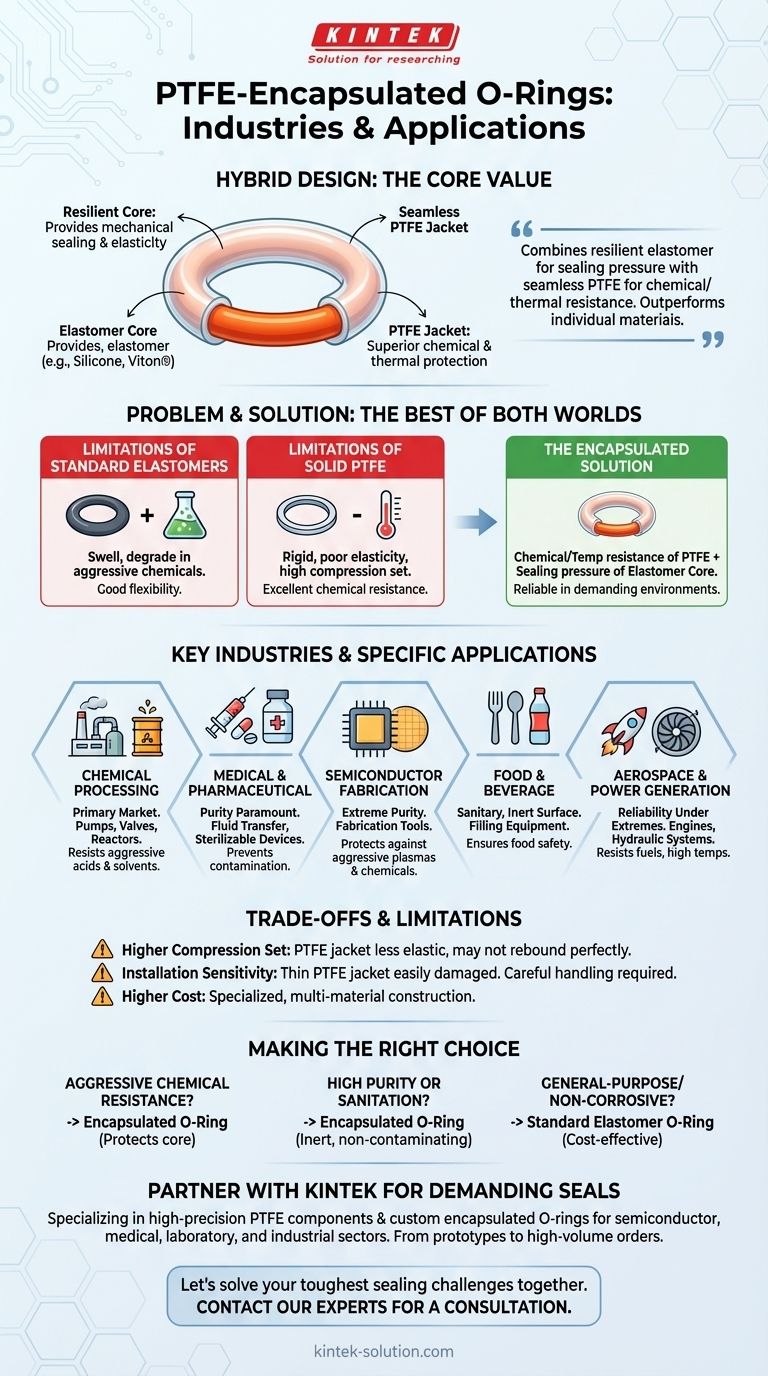

The core value of a PTFE-encapsulated O-ring is its hybrid design. It combines a resilient elastomer core for mechanical sealing with a seamless PTFE outer jacket for superior chemical and thermal protection, creating a seal that outperforms what either material could achieve on its own.

What Problem Do Encapsulated O-Rings Solve?

To understand where these O-rings are used, it's essential to first understand the limitations they overcome. Standard sealing solutions often force a compromise between chemical resistance and mechanical performance.

The Limitation of Standard Elastomers

Standard rubber O-rings, made from materials like Viton®, EPDM, or Silicone, are excellent at providing a flexible, tight seal. However, they can swell, degrade, or break down when exposed to highly corrosive chemicals or extreme temperatures.

The Limitation of Solid PTFE

Solid PTFE (Teflon®) is famous for being almost completely chemically inert and having a very wide temperature range. Unfortunately, solid PTFE is rigid and lacks the "memory" or elasticity of rubber, leading to poor sealing performance, leaks, and a high potential for compression set.

The "Best of Both Worlds" Solution

An encapsulated O-ring places a flexible elastomer core (often Silicone or Viton®) inside a thin, seamless jacket of PTFE. This design provides the chemical and temperature resistance of the PTFE jacket while relying on the inner core to provide the consistent, energized sealing pressure required for a reliable seal.

Key Industries and Their Specific Applications

The unique properties of these seals make them indispensable in demanding environments where seal failure is not an option.

Chemical Processing & Manufacturing

This is the primary market for encapsulated O-rings. They are used in pumps, valves, mechanical seals, and reactors that handle aggressive acids, solvents, and other corrosive fluids that would quickly destroy a standard elastomer.

Medical, Pharmaceutical, & Food Processing

In these industries, purity is paramount. The inert PTFE surface prevents contamination and doesn't react with process fluids or cleaning agents. They are critical in fluid transfer systems, filling equipment, and sterilizable devices.

Semiconductor Manufacturing

The fabrication of microchips requires extreme purity and resistance to aggressive plasmas and wet-etching chemicals. PTFE-encapsulated seals ensure a contaminant-free environment inside fabrication tools, protecting the integrity of the manufacturing process.

Aerospace & Power Generation

These sectors demand reliability under extreme conditions. Encapsulated O-rings are used to seal against aggressive fuels, hydraulic fluids, and high temperatures found in engines and power generation equipment, ensuring operational safety and longevity.

Understanding the Trade-offs and Limitations

While highly effective, encapsulated O-rings are not a universal solution. Understanding their limitations is key to using them correctly.

Higher Compression Set

The PTFE jacket is inherently less elastic than a bare elastomer. This means the O-ring may not rebound as perfectly after being compressed for a long time, especially at high temperatures. This must be considered in joint design.

Installation Sensitivity

The thin PTFE jacket is the key to the seal's chemical resistance. If it is scratched or nicked during installation on a sharp edge, its protective barrier is compromised, leading to premature failure. Careful handling is required.

Higher Cost

This is a specialized, high-performance product. The multi-material construction and manufacturing process make PTFE-encapsulated O-rings significantly more expensive than standard, single-material elastomer O-rings.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the demands of your specific environment.

- If your primary focus is aggressive chemical resistance: An encapsulated O-ring is an ideal choice to protect the seal's core and prevent chemical attack.

- If your primary focus is high purity or sanitation: The inert, non-contaminating PTFE surface is perfectly suited for medical, food, or semiconductor applications.

- If your primary focus is a general-purpose seal in a non-corrosive environment: A standard, more cost-effective elastomer O-ring is likely the more appropriate and economical solution.

Ultimately, choosing an encapsulated O-ring is a strategic decision to ensure seal integrity and reliability in your most critical and demanding applications.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical Processing | Pumps, Valves, Reactors | Resists aggressive acids and solvents |

| Medical & Pharmaceutical | Fluid Transfer, Sterilizable Devices | Ensures high purity and prevents contamination |

| Semiconductor | Fabrication Tools | Protects against aggressive plasmas and chemicals |

| Food & Beverage | Filling Equipment | Sanitary, inert surface for food safety |

| Aerospace & Power Generation | Engines, Hydraulic Systems | Reliability under extreme temperatures and pressures |

Need a reliable seal for a demanding application?

PTFE-encapsulated O-rings are a critical component for success in harsh environments. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom encapsulated O-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We combine precision production with custom fabrication expertise—from prototypes to high-volume orders—to deliver the exact sealing solution you need.

Let's solve your toughest sealing challenges together. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs