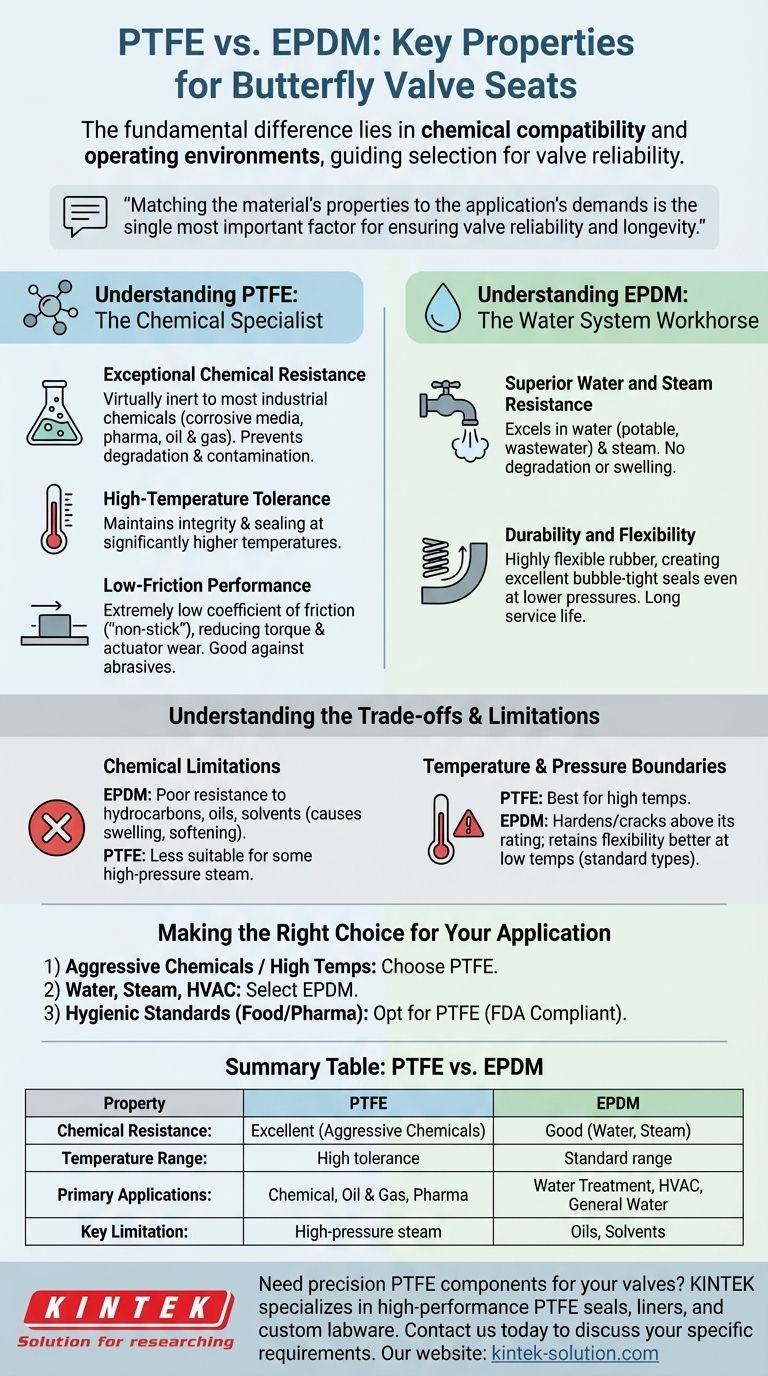

In butterfly valves, the fundamental difference between Polytetrafluoroethylene (PTFE) and Ethylene Propylene Diene Monomer (EPDM) seats lies in their chemical compatibility and operating environments. PTFE is the superior choice for applications involving aggressive chemicals and high temperatures, while EPDM is the industry standard for water and steam services. This distinction is the primary driver for selecting the correct valve seat material.

The choice between PTFE and EPDM is not about which material is inherently better, but which is precisely suited for the specific media flowing through the valve. Matching the material's properties to the application's demands is the single most important factor for ensuring valve reliability and longevity.

Understanding PTFE: The Chemical Specialist

PTFE, a fluoropolymer, is engineered for performance in the most demanding process conditions. Its unique molecular structure gives it properties that are essential for handling harsh substances safely and effectively.

Exceptional Chemical Resistance

PTFE is virtually inert to most industrial chemicals. This makes it the default choice for valve seats in chemical processing, pharmaceuticals, and oil and gas industries where corrosive media are common.

Its resistance to chemical attack prevents degradation of the valve seat, ensuring a reliable seal and preventing contamination of the process media.

High-Temperature Tolerance

PTFE maintains its structural integrity and sealing capability at significantly higher temperatures than EPDM. This makes it essential for applications involving hot liquids, gases, or high-temperature processing.

Low-Friction Performance

A key property of PTFE is its extremely low coefficient of friction. This "non-stick" characteristic results in lower torque requirements to operate the valve, reducing actuator wear and tear over the valve's lifespan. It also provides good resistance against abrasive substances.

Understanding EPDM: The Water System Workhorse

EPDM is a synthetic rubber compound optimized for durability and flexibility in less chemically aggressive environments. Its performance in water-based systems is unparalleled.

Superior Water and Steam Resistance

EPDM excels in applications involving water, be it potable water, wastewater, or steam. It does not degrade or swell with prolonged exposure to water, ensuring a consistent and tight seal.

This property makes it the ideal material for water treatment facilities, HVAC systems, and general water service lines.

Durability and Flexibility

As a type of rubber, EPDM is highly flexible, which allows it to create an excellent bubble-tight seal within the valve body, even under lower pressure conditions. This resilience contributes to its long service life in its intended applications.

Understanding the Trade-offs

Choosing the wrong material can lead to premature valve failure, leaks, and system downtime. The limitations of each material are just as important as their strengths.

Chemical Limitations

EPDM has poor resistance to many hydrocarbons, oils, and solvents. Using an EPDM-seated valve in a line carrying these substances will cause the seat to swell, soften, and degrade quickly, leading to seal failure.

Conversely, while PTFE has broad chemical resistance, it can be less suitable for certain high-pressure steam applications where EPDM's properties are more advantageous.

Temperature and Pressure Boundaries

PTFE is the clear choice for high-temperature services. Placing an EPDM-seated valve in a system that exceeds its temperature rating will cause the material to harden and crack, destroying its sealing ability.

At the other end, in extremely low temperatures, EPDM generally retains its flexibility better than standard PTFE, though specialized versions of PTFE can mitigate this.

Making the Right Choice for Your Application

Your decision should be guided entirely by the specific demands of your system. An honest assessment of your process media, temperature, and pressure will lead to the correct material choice.

- If your primary focus is handling aggressive chemicals or high temperatures: Choose PTFE for its unmatched chemical inertness and thermal stability.

- If your primary focus is managing water, steam, or HVAC systems: Select EPDM for its superior water resistance and reliable, flexible sealing performance.

- If your primary focus is maintaining hygienic standards for food or pharmaceuticals: Opt for PTFE due to its non-contaminating properties and FDA compliance.

Ultimately, matching the valve seat material to your specific process media is the most critical factor in ensuring system performance and longevity.

Summary Table:

| Property | PTFE | EPDM |

|---|---|---|

| Chemical Resistance | Excellent (aggressive chemicals) | Good (water, steam) |

| Temperature Range | High temperature tolerance | Standard temperature range |

| Primary Applications | Chemical processing, oil & gas, pharmaceuticals | Water treatment, HVAC, general water services |

| Key Limitation | Less suitable for high-pressure steam | Poor resistance to oils and solvents |

Need precision PTFE components for your valves? KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact chemical resistance and durability your application demands. Contact us today to discuss your specific requirements and let our solutions enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs