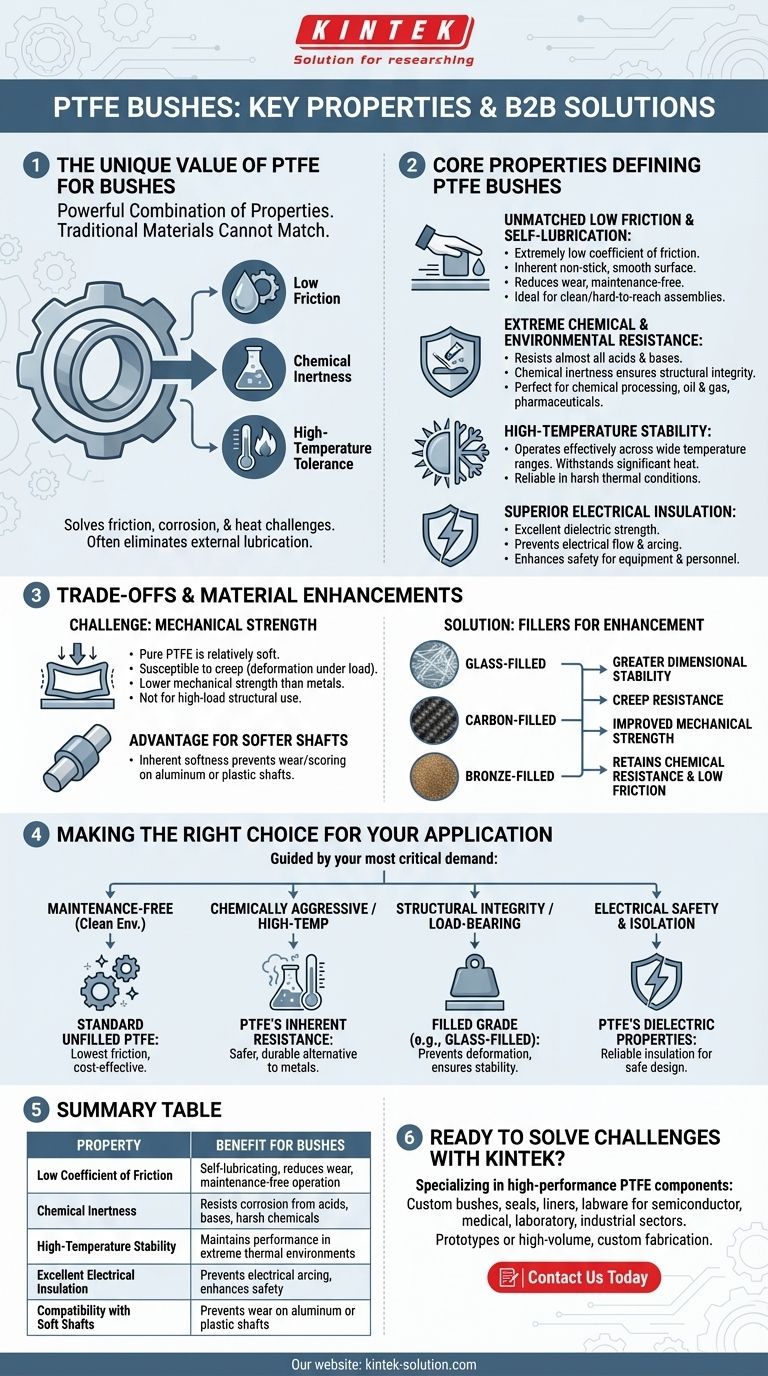

The unique value of PTFE for bushes stems from a powerful combination of properties that traditional materials cannot match. Its suitability is primarily defined by an extremely low coefficient of friction, exceptional chemical inertness, and high-temperature tolerance, making it a self-lubricating solution for demanding operational environments.

While many materials excel in one area, PTFE's advantage lies in its unique fusion of characteristics. It solves the simultaneous challenges of friction, corrosion, and heat in a single, reliable material, often eliminating the need for external lubrication entirely.

The Core Properties Defining PTFE Bushes

To understand if PTFE is the right choice, we must examine the specific properties that make it a high-performance polymer for bearing applications.

Unmatched Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any known solid material. This creates an inherently non-stick, smooth surface.

This property means that PTFE bushes are self-lubricating. They reduce wear and maintain the efficiency of moving parts without the need for constant application of oil or grease, which is critical in clean environments or hard-to-reach assemblies.

Extreme Chemical and Environmental Resistance

PTFE is highly resistant to almost all corrosive chemicals, acids, and bases. This chemical inertness ensures the bush maintains its structural integrity and performance over time.

This makes it the ideal choice for industries like chemical processing, oil and gas, and pharmaceuticals, where metal bearings would quickly degrade and fail.

High-Temperature Stability

PTFE bushes can operate effectively across a wide range of temperatures, withstanding significant heat without compromising their function.

This ensures that components in high-temperature machinery remain operational and reliable under harsh thermal conditions.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, a property known as high dielectric strength. This makes it ideal for applications where preventing electrical flow is a safety or operational requirement.

This characteristic helps prevent electrical arcing between components, enhancing both equipment and personnel safety.

Understanding the Trade-offs and Material Enhancements

While its core properties are exceptional, understanding the limitations of pure PTFE is crucial for proper application.

The Challenge of Mechanical Strength

In its pure, unfilled state, PTFE is a relatively soft material. It can be susceptible to creep (deformation under sustained load) and has lower mechanical strength compared to metals.

This makes unfilled PTFE unsuitable for high-load or high-pressure structural applications where dimensional stability is the primary concern.

The Role of Fillers: Enhancing Performance

To overcome its mechanical limitations, PTFE is often blended with fillers like glass, carbon, or bronze. These composite materials significantly improve performance.

Glass-filled PTFE, for example, offers much greater dimensional stability, creep resistance, and overall mechanical strength while retaining excellent chemical resistance and low friction.

Suitability for Softer Shafts

The inherent softness of PTFE can be a distinct advantage. When used with softer shaft materials, such as aluminum or certain plastics, the PTFE bush will not cause wear or scoring on the shaft itself.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical demand of your specific design.

- If your primary focus is maintenance-free operation in a clean environment: Standard, unfilled PTFE offers the lowest friction and is a highly cost-effective solution.

- If your primary focus is performance in a chemically aggressive or high-temperature setting: PTFE's inherent resistance makes it a far safer and more durable choice than most metal bearings.

- If your primary focus is structural integrity and load-bearing capacity: A filled grade, such as glass-filled PTFE, is essential to prevent deformation and ensure long-term stability under pressure.

- If your primary focus is electrical safety and isolation: PTFE's dielectric properties provide reliable insulation that is fundamental to safe equipment design.

Ultimately, selecting PTFE is about leveraging its unique properties to solve problems where conventional materials fall short.

Summary Table:

| Property | Benefit for Bushes |

|---|---|

| Low Coefficient of Friction | Self-lubricating, reduces wear, maintenance-free operation |

| Chemical Inertness | Resists corrosion from acids, bases, and harsh chemicals |

| High-Temperature Stability | Maintains performance in extreme thermal environments |

| Excellent Electrical Insulation | Prevents electrical arcing, enhances safety |

| Compatibility with Soft Shafts | Prevents wear on shafts made of aluminum or plastics |

Ready to solve your friction, corrosion, and heat challenges with precision PTFE bushes?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom bushes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise in custom fabrication ensures you get the exact solution for your application.

Contact us today to discuss how our PTFE bushes can enhance your equipment's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Can PTFE bushes be customized for specific applications? Tailor Geometry, Material, and Surface for Peak Performance

- What industries commonly use Teflon CNC machined parts? Critical Solutions for Aerospace, Medical & More

- What is the coefficient of friction for Pure Teflon? Unlock Superior Low-Friction Performance

- Which type of PTFE backup ring is better for harsh environments? Choose Spiral Rings for Maximum Reliability

- What material are PTFE heat press sheets made from? Unlock Consistent, Professional Results

- What factors should be considered when choosing a filler for PTFE? Enhance Performance for Your Application

- Why is mineral-filled PTFE used in medical and food industries? | Superior Durability Meets FDA-Compliant Safety

- What material are PTFE washers made from? Unlocking the Power of PTFE for Demanding Seals