PTFE washers are made from the synthetic fluoropolymer Polytetrafluoroethylene. This high-performance plastic is a member of the same family as the material famously known by its DuPont brand name, Teflon, and is engineered for its exceptional chemical resistance and extremely low friction.

The core reason for choosing PTFE is not simply its material composition, but its unique ability to function reliably in harsh chemical and high-temperature environments where common elastomers like rubber would degrade and fail.

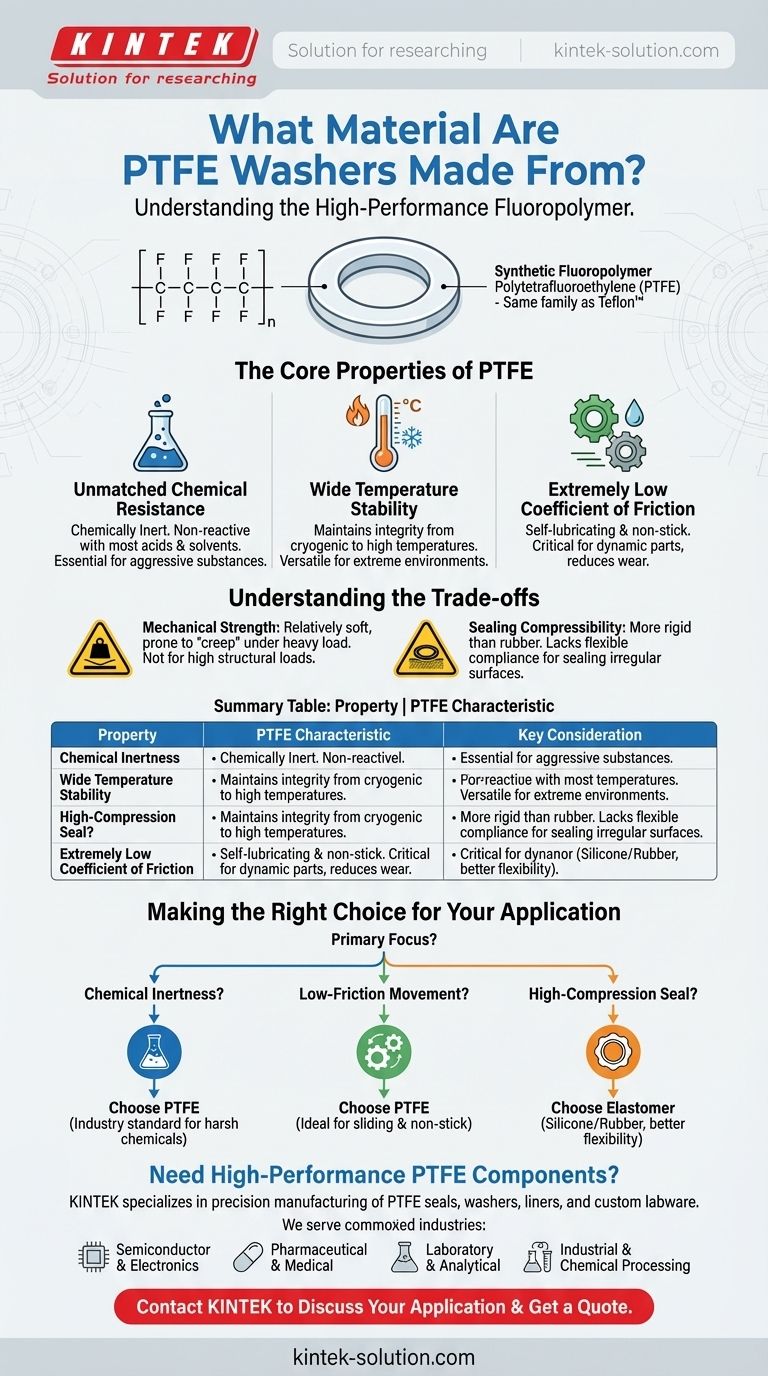

The Core Properties of PTFE

Understanding the material requires looking beyond the name and focusing on the three properties that define its performance in demanding applications. These characteristics are the reason PTFE is specified in industries from aerospace to chemical processing.

Unmatched Chemical Resistance

PTFE is chemically inert, meaning it does not react with the vast majority of industrial chemicals, acids, and solvents.

This non-reactive nature makes it an essential sealing material in applications involving aggressive substances that would corrode metals or dissolve other plastics.

Wide Temperature Stability

PTFE washers maintain their integrity and performance across an exceptionally broad temperature range.

They can operate effectively in cryogenic conditions as well as in high-temperature environments, a versatility that most rubber and plastic washers cannot match.

Extremely Low Coefficient of Friction

This material has one of the lowest coefficients of friction of any known solid, giving it a distinct "non-stick" or self-lubricating quality.

This property is critical in dynamic applications with moving parts, as it reduces wear and prevents galling between surfaces without the need for external lubricants.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not universally superior. Its limitations are just as important to understand for proper application. An expert advisor recognizes that no material is perfect for every job.

Mechanical Strength and Creep

PTFE is a relatively soft material. Under a constant, heavy load, it can slowly deform over time in a process known as "creep."

This makes it unsuitable for high-load structural applications where a harder plastic or metal washer would be required to maintain dimensional stability.

Sealing Compressibility

While it is an effective sealing material, PTFE is significantly more rigid than elastomers like silicone or natural rubber.

Rubber washers deform easily to fill microscopic gaps and surface imperfections, creating a high-compression, often watertight seal. A PTFE washer provides a reliable gasket but lacks the flexible compliance of rubber for sealing against irregular surfaces.

Making the Right Choice for Your Application

Selecting the correct washer material depends entirely on the primary demands of your specific use case.

- If your primary focus is chemical inertness: PTFE is the industry-standard choice for sealing against aggressive solvents, acids, and corrosive agents.

- If your primary focus is low-friction movement: PTFE provides an ideal self-lubricating surface for sliding components, bearings, and non-stick assemblies.

- If your primary focus is a high-compression, watertight seal: A more compliant elastomer like silicone or rubber is often a more effective choice due to its superior flexibility.

Ultimately, understanding these core material properties empowers you to select the right component for long-term reliability and performance.

Summary Table:

| Property | PTFE Washer Characteristic | Key Consideration |

|---|---|---|

| Chemical Resistance | Inert to most acids, solvents, and corrosive agents. | Ideal for harsh chemical environments. |

| Temperature Range | Stable from cryogenic to high temperatures. | Versatile for extreme temperature applications. |

| Friction | Extremely low coefficient; self-lubricating. | Perfect for dynamic, non-stick applications. |

| Limitation: Creep | Can deform under constant, heavy load. | Not suitable for high-load structural uses. |

| Limitation: Compressibility | Less flexible than rubber or silicone. | May not seal as effectively on irregular surfaces. |

Need High-Performance PTFE Components?

Understanding the properties of PTFE is the first step. Applying that knowledge to source the right component is the next. KINTEK specializes in the precision manufacturing of PTFE seals, washers, liners, and custom labware.

We serve industries where failure is not an option, including:

- Semiconductor and Electronics Manufacturing

- Pharmaceutical and Medical Device Production

- Laboratory and Analytical Equipment

- Industrial and Chemical Processing

Whether you require a standard part or a custom-fabricated solution—from prototypes to high-volume orders—our expertise ensures you get a component engineered for reliability and performance.

Contact KINTEK today to discuss your specific application requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs