Yes, PTFE bushes are highly customizable to meet precise engineering requirements. This customization extends far beyond simple dimensions, allowing for modifications to the material's core properties, its physical shape, and its surface characteristics to create a component perfectly suited for a specific operational environment.

The key to customizing PTFE is understanding that it's not a single material, but a versatile platform. True customization involves a three-part process: selecting the right PTFE compound for performance, defining the exact physical geometry for fit, and specifying any necessary surface treatments for integration.

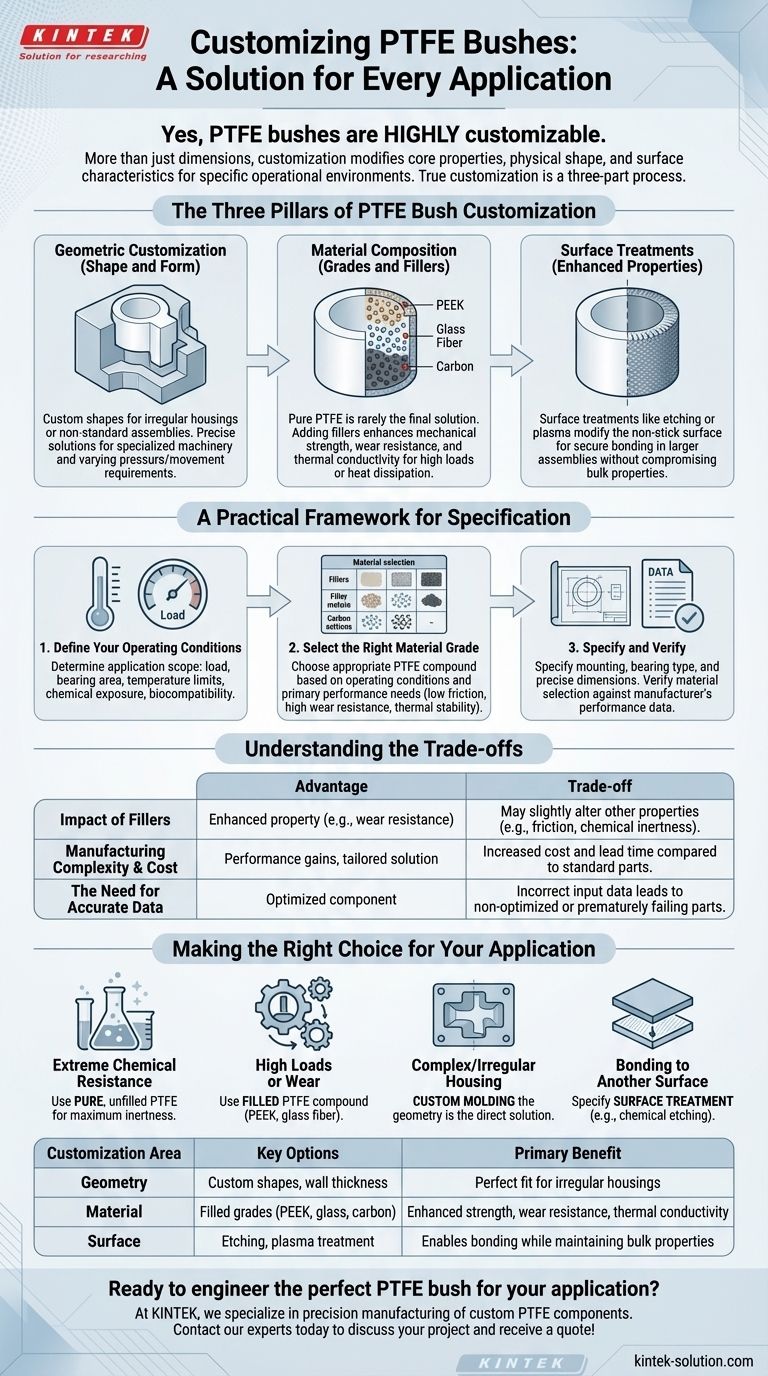

The Three Pillars of PTFE Bush Customization

To effectively specify a custom PTFE bush, you must consider three distinct areas of modification. Each one addresses a different aspect of the component's performance and function.

Geometric Customization (Shape and Form)

The most straightforward form of customization is adjusting the physical shape. PTFE can be manufactured into custom shapes to fit irregularly shaped housings or non-standard assemblies.

This ensures a precise bearing solution even in specialized machinery where off-the-shelf components would fail. The design can also be adapted for different pressure and movement requirements, from stable, rigid walls to highly flexible forms for high-frequency motion.

Material Composition (Grades and Fillers)

Pure PTFE is rarely the final solution for demanding applications. Manufacturers create various grades of PTFE by adding fillers to the base material.

Choosing the right filler is critical for performance. Adding materials like PEEK, glass fiber, or carbon can dramatically enhance properties like mechanical strength, wear resistance, and thermal conductivity, tailoring the bush to withstand high loads or dissipate heat more effectively.

Surface Treatments (Enhanced Properties)

The naturally non-stick, non-reactive surface of PTFE is a significant advantage, but it can make bonding difficult. For applications requiring adhesion to other components, PTFE bushes can undergo surface treatments.

Processes like etching, plasma, or chemical treatments modify the surface of the PTFE, allowing it to be securely bonded within a larger assembly without compromising the bulk properties of the material.

A Practical Framework for Specification

Creating a successful custom component requires a systematic approach. Following a clear design process ensures all operational demands are met.

Define Your Operating Conditions

First, you must determine the full scope of the application's environment. This includes calculating the load and required bearing area, as well as defining the operational temperature limits.

You must also account for any unusual conditions, such as exposure to corrosive chemicals or the need for biocompatibility, as PTFE is highly non-reactive and corrosion-resistant.

Select the Right Material Grade

Based on the operating conditions, you can select the appropriate PTFE compound. The choice of filler will be dictated by the primary performance requirement, whether it's low friction, high wear resistance, or thermal stability.

Specify and Verify

The final step is to specify the mounting method, bearing type, and precise dimensions. It is essential to verify your material selection against the performance data sheet provided by the manufacturer. All technical data should be cross-checked to confirm its suitability for your intended application.

Understanding the Trade-offs

While customization offers significant advantages, it's important to be aware of the associated trade-offs to make an informed decision.

The Impact of Fillers

Adding a filler to enhance one property can sometimes slightly alter another. For example, a filler that increases wear resistance might subtly change the coefficient of friction or the material's chemical inertness compared to pure PTFE.

Manufacturing Complexity and Cost

Custom shapes, unique material compounds, and additional surface treatments will inevitably increase the cost and lead time compared to standard, off-the-shelf bushes. This investment must be weighed against the performance gains and the cost of failure if a standard part is used improperly.

The Need for Accurate Data

The success of a custom part depends entirely on the accuracy of the input data. Incorrect load calculations or an incomplete understanding of the thermal environment will result in a component that is not optimized and may fail prematurely.

Making the Right Choice for Your Application

Use your primary operational goal to guide your customization strategy.

- If your primary focus is extreme chemical resistance: A pure, unfilled grade of PTFE is typically the best choice to ensure maximum inertness.

- If your primary focus is withstanding high loads or wear: A filled PTFE compound with a reinforcing agent like PEEK or glass fiber is necessary.

- If your primary focus is fitting a complex or irregular housing: Custom molding the geometry of the bush is the direct solution.

- If your primary focus is bonding the bush to another surface: You must specify a surface treatment like chemical etching to enable adhesion.

By systematically addressing these factors, you can leverage the remarkable versatility of PTFE to engineer a solution tailored to your exact needs.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Geometry | Custom shapes, wall thickness | Perfect fit for irregular housings |

| Material | Filled grades (PEEK, glass, carbon) | Enhanced strength, wear resistance, thermal conductivity |

| Surface | Etching, plasma treatment | Enables bonding while maintaining bulk properties |

Ready to engineer the perfect PTFE bush for your application?

At KINTEK, we specialize in precision manufacturing of custom PTFE components like seals, liners, and labware. Whether you need a prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, our expertise in material science and custom fabrication ensures a solution tailored to your exact operational demands—from complex geometries to specific performance requirements.

Contact our experts today to discuss your project and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials