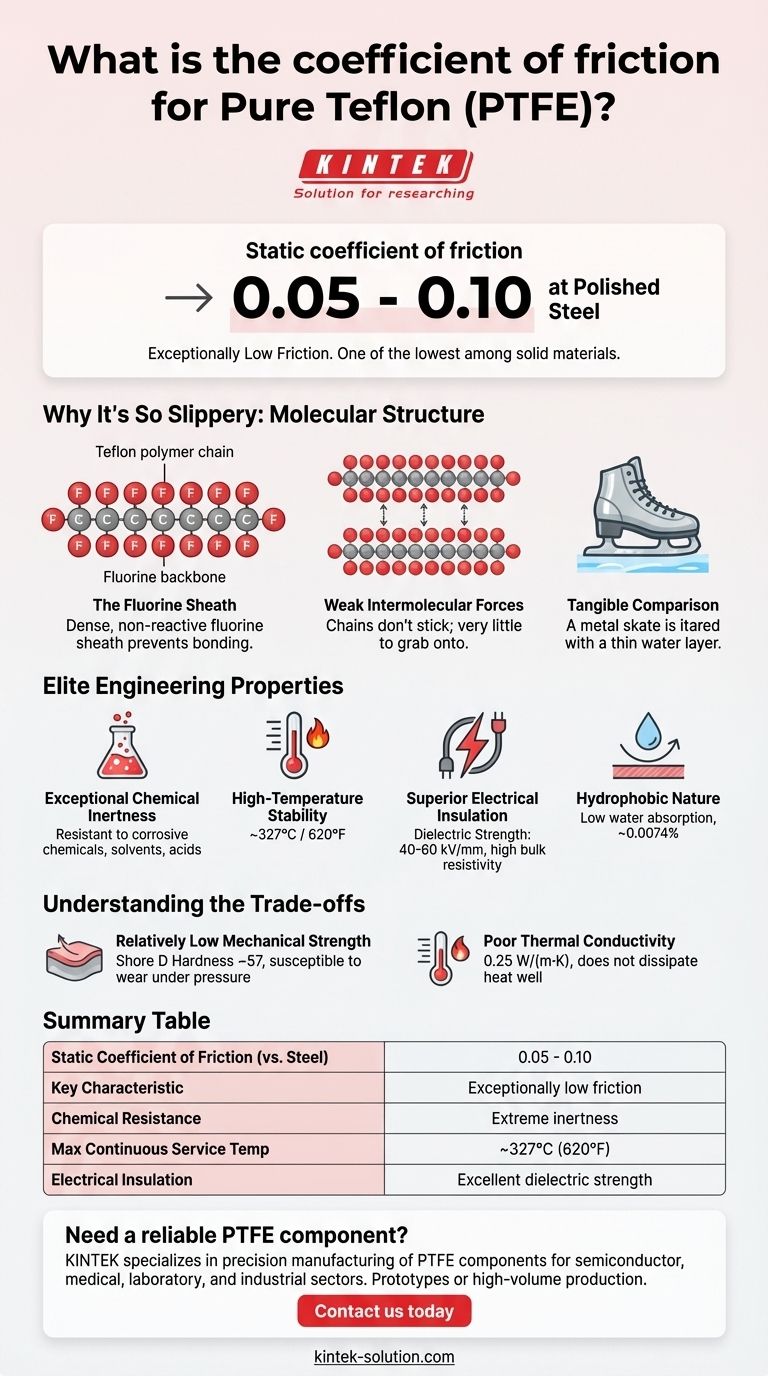

To be precise, the static coefficient of friction for pure Teflon (PTFE) against polished steel is exceptionally low, typically cited in the range of 0.05 to 0.10. This value is among the lowest of any known solid material, making it a benchmark for low-friction applications.

The core reason for Teflon's unique properties is not just its slipperiness, but its rare combination of low friction, extreme chemical inertness, and high-temperature stability. Understanding this trio of characteristics is the key to leveraging it effectively in any engineering context.

What Makes Teflon So Slippery?

The remarkably low friction of Teflon isn't magic; it's a direct result of its unique molecular structure. The properties emerge from the powerful bonds within its molecules and the weak forces between them.

The Fluorine Sheath

Teflon is a polymer, a long chain of carbon atoms. Each carbon atom is bonded to two fluorine atoms. These carbon-fluorine bonds are incredibly strong and stable.

The fluorine atoms effectively wrap around the carbon backbone, creating a dense, non-reactive "sheath" of electrons. This sheath prevents other molecules from getting close and forming bonds.

Weak Intermolecular Forces

Because of this protective fluorine sheath, the individual Teflon polymer chains do not stick well to each other or to other surfaces. The forces between molecules (van der Waals forces) are extremely weak.

When another material attempts to slide across Teflon, there is very little to grab onto at a molecular level. This results in the "non-stick" and low-friction properties for which it is famous.

A Tangible Comparison

The friction of Teflon is often compared to that of a metal skate gliding on a thin layer of water on ice. It is an outlier among solid materials, offering a level of slipperiness that few other plastics or metals can approach.

Beyond Friction: Key Engineering Properties

While its low friction is its most famous trait, Teflon's utility comes from a combination of other elite properties that allow it to perform under demanding conditions.

Exceptional Chemical Inertness

Teflon is one of the most non-reactive substances known. It is resistant to nearly all corrosive chemicals, solvents, and acids. Only highly reactive alkali metals can affect it.

High-Temperature Stability

It maintains its properties over a wide range of temperatures. Pure Teflon has a high melting point of approximately 327°C (620°F) and also resists becoming brittle at very low temperatures.

Superior Electrical Insulation

Due to its strong carbon-fluorine bonds, Teflon is an excellent electrical insulator. It possesses very high dielectric strength (40-60 kV/mm) and bulk resistivity, making it ideal for high-frequency electronics and cable insulation.

Hydrophobic Nature

Teflon has a very low water absorption capacity (around 0.0074%). This resistance to moisture helps maintain its electrical and mechanical properties in humid environments.

Understanding the Trade-offs

No material is perfect, and Teflon's unique advantages come with practical limitations that are critical to consider in any design.

Relatively Low Mechanical Strength

Teflon is a relatively soft material, with a Shore D hardness of around 57. It is not suitable for high-load structural applications on its own, as it can be susceptible to scratches, wear, and deformation under pressure.

Poor Thermal Conductivity

While it can withstand high temperatures, Teflon is a poor conductor of heat (0.25 W/(m·K)). This makes it an excellent thermal insulator but means it will not dissipate heat effectively in applications where that is required.

How to Apply This to Your Project

Choosing to use Teflon depends entirely on which of its properties is most critical for your goal.

- If your primary focus is minimizing friction: Teflon's coefficient is among the lowest possible for a solid, making it the default choice for non-stick coatings, slide plates, and low-load bearings.

- If your primary focus is chemical resistance: Its inertness is invaluable for seals, gaskets, and vessel linings that will be exposed to highly corrosive substances.

- If your primary focus is electrical insulation: Its high dielectric strength makes it a premier material for insulating high-frequency, high-voltage wires and components.

Ultimately, leveraging Teflon successfully comes from understanding that its slipperiness is just one part of a powerful but specific set of engineering characteristics.

Summary Table:

| Property | Value / Description |

|---|---|

| Static Coefficient of Friction (vs. Steel) | 0.05 - 0.10 |

| Key Characteristic | Exceptionally low friction |

| Chemical Resistance | Extreme inertness |

| Max Continuous Service Temp | ~327°C (620°F) |

| Electrical Insulation | Excellent dielectric strength |

Need a reliable PTFE component that leverages these unique properties?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures your components deliver superior low-friction performance, chemical resistance, and thermal stability.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers