To put it simply, mineral-filled PTFE is used in medical and food industries because it solves a critical engineering challenge: it combines the exceptional mechanical strength and wear resistance needed for industrial machinery with the chemical inertness and non-stick purity required for safe contact with consumable products. This composite material is tough enough for demanding applications like seals and valves yet remains non-toxic, non-reactive, and FDA compliant.

The core problem is that standard PTFE is chemically safe but mechanically soft. By adding mineral fillers, engineers create a reinforced material that is both durable enough for high-wear industrial environments and pure enough for the strictest sanitary regulations.

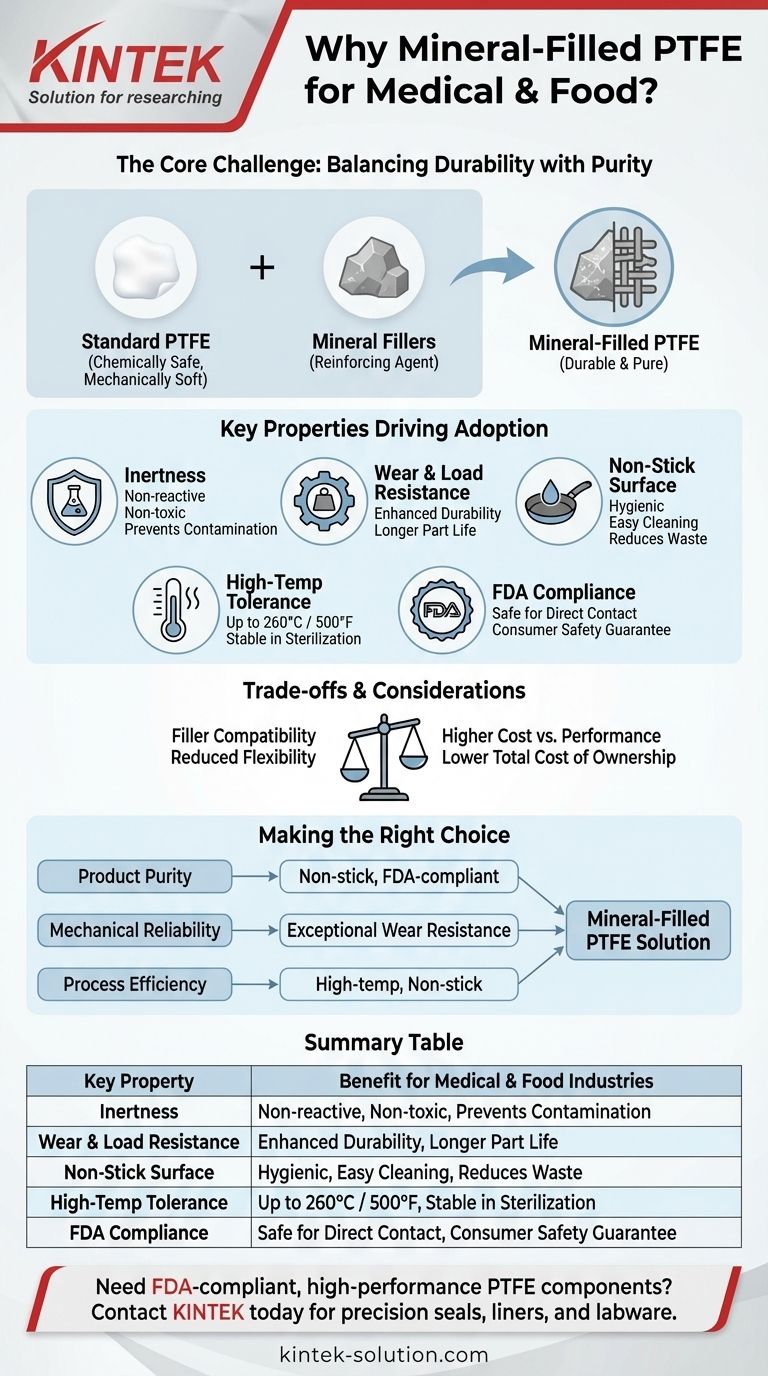

The Core Challenge: Balancing Durability with Purity

In food and medical processing, materials face a dual mandate. They must withstand intense mechanical stress, high temperatures, and aggressive cleaning regimens while ensuring the absolute purity of the final product.

The Limitation of Standard PTFE

Pure Polytetrafluoroethylene (PTFE) is famous for its non-stick surface and near-universal chemical resistance. However, it is a relatively soft polymer.

In applications involving high pressure or friction—such as gaskets, valve seats, or conveyor belts—unfilled PTFE can deform or wear down quickly, leading to equipment failure and potential contamination.

The Role of Mineral Fillers

Mineral fillers act as a reinforcing agent within the PTFE matrix. Think of it like adding rebar to concrete.

This reinforcement dramatically improves key physical properties like load-bearing capacity and resistance to wear and abrasion. The result is a material that doesn't just survive in an industrial setting, but excels.

Key Properties Driving Adoption in Regulated Industries

The unique combination of properties offered by mineral-filled PTFE makes it an ideal solution for components that come into direct contact with food, pharmaceuticals, and medical products.

Unmatched Chemical Inertness

The material is non-reactive and non-toxic. It does not leach chemicals or react with corrosive fluids, aggressive cleaning agents, or the products themselves.

This ensures that the final product remains free from contamination, maintaining its intended purity and quality.

Superior Wear and Load Resistance

This is the primary benefit of adding mineral fillers. Components like valve seats, seals, and washers made from this material last significantly longer.

This enhanced durability increases operational efficiency, reduces maintenance-related downtime, and boosts overall productivity in processing plants.

A Critical Non-Stick Surface

PTFE's legendary non-stick properties prevent food, powders, and other materials from building up on equipment surfaces.

This quality is crucial for hygiene, as it simplifies cleaning protocols and minimizes the risk of bacterial growth. It also reduces product waste by ensuring an easy release from molds and conveyor belts.

High-Temperature Tolerance

Mineral-filled PTFE can operate at continuous temperatures up to 260°C (500°F).

This allows it to perform reliably in high-temperature processes such as baking, confectionery production, and steam sterilization without degrading or losing its structural integrity.

FDA Compliance and Food Safety

Crucially, specific grades of mineral-filled PTFE are formulated to be FDA compliant.

This certification is a non-negotiable requirement for any material in direct contact with food or medical products, providing a guarantee of its safety for consumer use.

Understanding the Trade-offs

While highly effective, mineral-filled PTFE is a specialized material, and choosing it requires acknowledging certain considerations.

Filler-Specific Compatibility

While the PTFE base is almost universally inert, the specific mineral filler used may have rare chemical vulnerabilities. It is essential to ensure the chosen filler is compatible with all chemicals used in the process, especially aggressive cleaning agents.

Reduced Flexibility

Adding rigid mineral particles can slightly reduce the flexibility of the base PTFE. For applications requiring extreme flexing or very soft, conformable seals, the specific grade and filler percentage must be carefully evaluated.

Cost vs. Performance

Mineral-filled PTFE is a high-performance polymer and is typically more expensive than commodity plastics or standard PTFE. However, its cost is justified by longer part life, reduced machine downtime, and enhanced product safety, leading to a lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your most critical operational goal.

- If your primary focus is product purity and hygiene: Mineral-filled PTFE's non-stick, non-reactive, and FDA-compliant nature provides the highest assurance of safety and cleanability.

- If your primary focus is mechanical reliability and uptime: The material's exceptional wear resistance ensures longer life for critical components, directly reducing costly maintenance and production stops.

- If your primary focus is process efficiency: Its performance at high temperatures and non-stick surface combine to reduce waste and enable faster, more consistent production cycles.

Ultimately, choosing mineral-filled PTFE is an investment in a material that refuses to compromise between industrial performance and sanitary safety.

Summary Table:

| Key Property | Benefit for Medical & Food Industries |

|---|---|

| Chemical Inertness | Non-reactive, non-toxic, prevents product contamination |

| Wear & Load Resistance | Enhanced durability for seals, valves, and high-wear parts |

| Non-Stick Surface | Easy cleaning, reduces bacterial growth and product waste |

| High-Temperature Tolerance | Stable performance up to 260°C (500°F) for sterilization and processing |

| FDA Compliance | Certified safe for direct contact with food and medical products |

Need FDA-compliant, high-performance PTFE components for your medical, food, or industrial applications?

KINTEK specializes in precision-manufactured mineral-filled PTFE seals, liners, and labware that deliver unmatched durability and purity. From custom prototypes to high-volume orders, we ensure your components meet strict sanitary standards while withstanding demanding operational environments.

Contact KINTEK today to discuss your project requirements and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments