In short, Teflon seals are high-performance sealing components defined by their exceptional resistance to chemicals, tolerance for extreme temperatures, and uniquely low coefficient of friction. These properties make them a default choice for demanding industrial applications where conventional elastomer seals would fail.

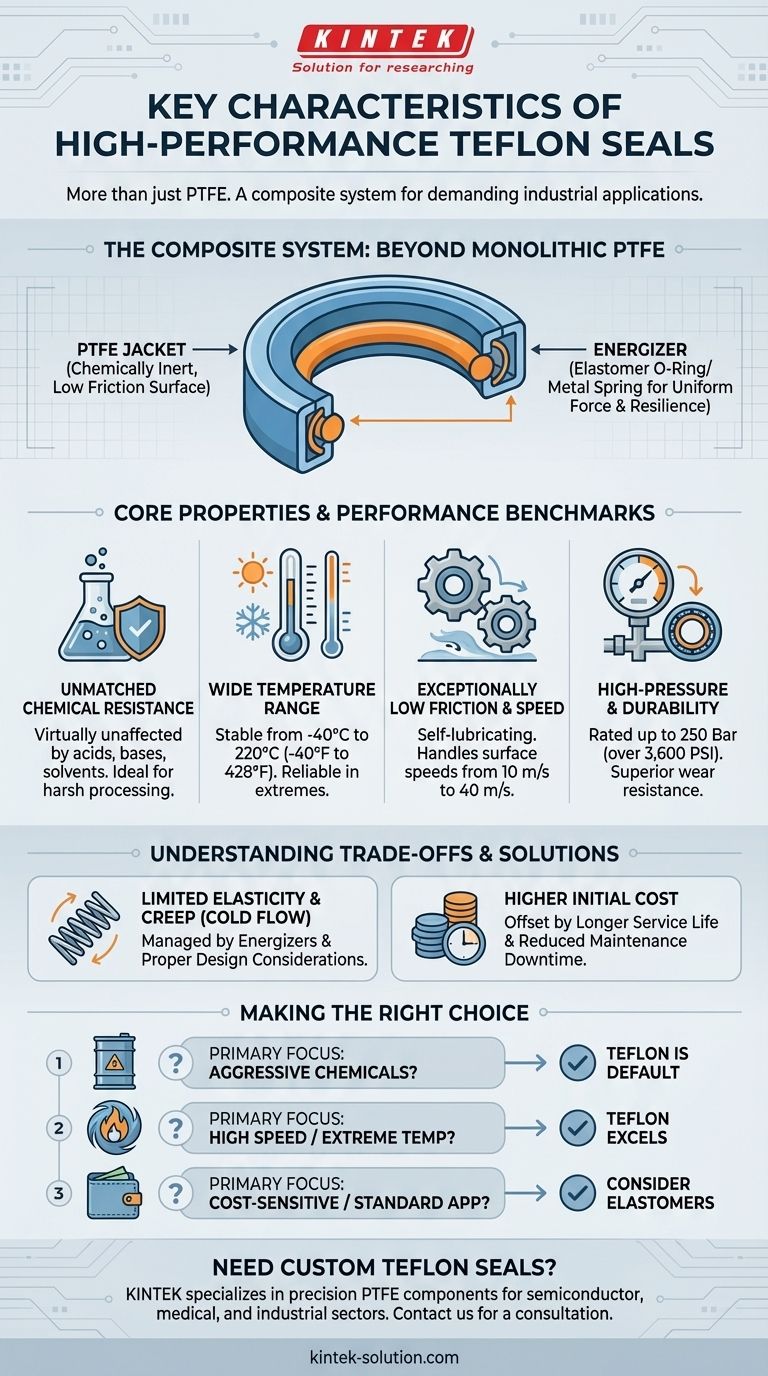

The key takeaway is that "Teflon seal" often refers to a composite system, not just a simple ring of PTFE. Understanding how the PTFE sealing element works with an energizer (like an elastomer or metal spring) is critical to leveraging its full potential in high-pressure and dynamic applications.

Deconstructing the Core Properties

To understand if a Teflon (PTFE) seal is the right solution, we must look beyond the name and analyze its fundamental characteristics. These properties are what distinguish it from other sealing materials.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is virtually unaffected by acids, bases, solvents, and other corrosive agents that would rapidly degrade standard rubber or plastic seals.

This makes PTFE seals essential for applications in chemical processing, pharmaceuticals, and oil and gas where media compatibility is a primary concern.

Wide Operational Temperature Range

Teflon seals function reliably across an exceptionally broad temperature spectrum, typically from -40°C to 220°C (-40°F to 428°F).

This stability allows them to perform consistently in environments with significant heat cycles or in applications involving cryogenic fluids or high-temperature processes, where elastomers would become brittle or break down.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "self-lubricating" characteristic is a significant advantage.

It minimizes heat generation from friction, reduces energy consumption in rotating equipment, and prevents the stick-slip phenomenon that can cause jerky movements in hydraulic and pneumatic systems.

Superior Wear Resistance and Durability

The low-friction nature of Teflon directly contributes to its excellent wear resistance. By minimizing abrasive forces, the seal lasts longer and requires minimal maintenance.

This inherent durability ensures a long service life, reducing downtime and operational costs, especially in continuous-duty machinery.

Key Performance Benchmarks

Beyond its material properties, a Teflon seal's performance is defined by its ability to handle severe operational demands. These benchmarks are often achieved through its composite design.

High-Pressure Capability

Engineered Teflon seals can handle significant system pressures, often rated for sealing up to 250 Bar (over 3,600 PSI).

This capability is crucial for hydraulic cylinders, high-pressure valves, and other fluid power systems where containing force is the primary objective.

High-Speed Operation

In dynamic applications, Teflon seals excel. They are designed for shaft speeds ranging from 10 m/s to as high as 40 m/s.

The low-friction surface prevents overheating and premature failure in high-speed rotating equipment like motors, pumps, and gearboxes, where standard lip seals would quickly burn out.

The Composite System: More Than Just PTFE

Many high-performance Teflon seals are not monolithic. They combine a PTFE jacket with an energizing element, such as an elastomer O-ring or a stainless steel spring.

The PTFE provides the low-friction, chemically resistant sealing surface. The energizer provides the constant, uniform force needed to maintain a tight seal, compensating for the PTFE's limited elasticity.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging the limitations of PTFE to ensure proper application.

Lack of Elastic Memory

Unlike rubber, pure PTFE is not highly elastic. It does not readily spring back to its original shape after being compressed.

This is precisely why energizers are so common in PTFE seal designs. The energizer provides the resilience that the PTFE material lacks on its own.

Susceptibility to Creep (Cold Flow)

Under sustained pressure and temperature, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow."

Proper seal design and hardware engineering, such as using appropriate clearances and support rings, are critical to manage this effect and ensure long-term sealing integrity.

Higher Initial Cost

As a high-performance material, Teflon and the complex manufacturing of composite seals often result in a higher upfront cost compared to standard nitrile or Viton seals.

This cost must be weighed against the benefits of longer service life, reduced maintenance, and the ability to operate in conditions where other materials would fail.

Making the Right Choice for Your Application

Selecting the correct seal is about matching the material's strengths to your primary operational challenge.

- If your primary focus is aggressive chemical exposure: Teflon seals are the default choice due to their near-universal chemical inertness.

- If your primary focus is high-speed rotating equipment: The low-friction properties of Teflon seals minimize heat generation and wear, making them ideal.

- If your primary focus is extreme temperatures: With an operational range from -40°C to 220°C, these seals outperform most standard elastomers.

- If your primary focus is a cost-sensitive, standard application: A simpler elastomeric seal may be a more economical and perfectly suitable alternative if conditions are not severe.

By matching these distinct characteristics to your specific operational demands, you can ensure reliable and long-lasting sealing performance.

Summary Table:

| Key Characteristic | Performance Benchmark | Primary Benefit |

|---|---|---|

| Chemical Resistance | Virtually inert to acids, bases, solvents | Ideal for harsh chemical environments |

| Temperature Range | -40°C to 220°C (-40°F to 428°F) | Stable performance in extreme heat/cold |

| Friction Coefficient | One of the lowest of any solid material | Self-lubricating, reduces energy use |

| Pressure Capability | Up to 250 Bar (over 3,600 PSI) | Reliable sealing in high-pressure systems |

| Speed Operation | 10 m/s to 40 m/s | Excellent for high-speed rotating equipment |

Need High-Performance Teflon Seals for Your Application?

KINTEK specializes in manufacturing precision PTFE components, including custom Teflon seals, for the semiconductor, medical, laboratory, and industrial sectors. Our seals deliver:

- Superior chemical resistance to handle aggressive media

- Reliable performance across extreme temperatures

- Low-friction operation for energy efficiency and long life

- Custom fabrication from prototypes to high-volume orders

Let us provide a sealing solution that meets your exact requirements. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What configurations are available for PTFE rotary shaft seals? Optimize Performance with Lip, Shell & Material Options

- What factors should be considered when selecting a PTFE coating thrust washer? Optimize Performance and Lifespan

- What temperature range can PTFE seals typically operate in? From Cryogenic -200°C to High-Temp 260°C

- How does Teflon gland packing compare to alternatives? Choose the Right Material for Your Seals

- How does FR4 PCB material compare to PTFE in terms of electrical properties? Choose the Right Material for Your Application.

- What are symptoms of temperature-induced PTFE lip seal failure? Identify the Cause of Your Leaks

- What material are PTFE ring gaskets made from? Unlock Superior Chemical & Thermal Sealing

- What challenges do elastomeric seals face in oil and gas operations? Ensuring Reliability Under Extreme Conditions