When selecting a PTFE-coated thrust washer, the most critical factors to evaluate are its load capacity, operating temperature range, chemical environment, and compatibility with mating surfaces. These elements, combined with the quality of the coating and its manufacturing process, determine whether the washer will succeed or fail in your application.

The key is to view the washer not just as a piece of PTFE, but as an engineered system. The performance you achieve depends on the synergy between the base metal, the coating quality, and the specific operational stresses it will endure.

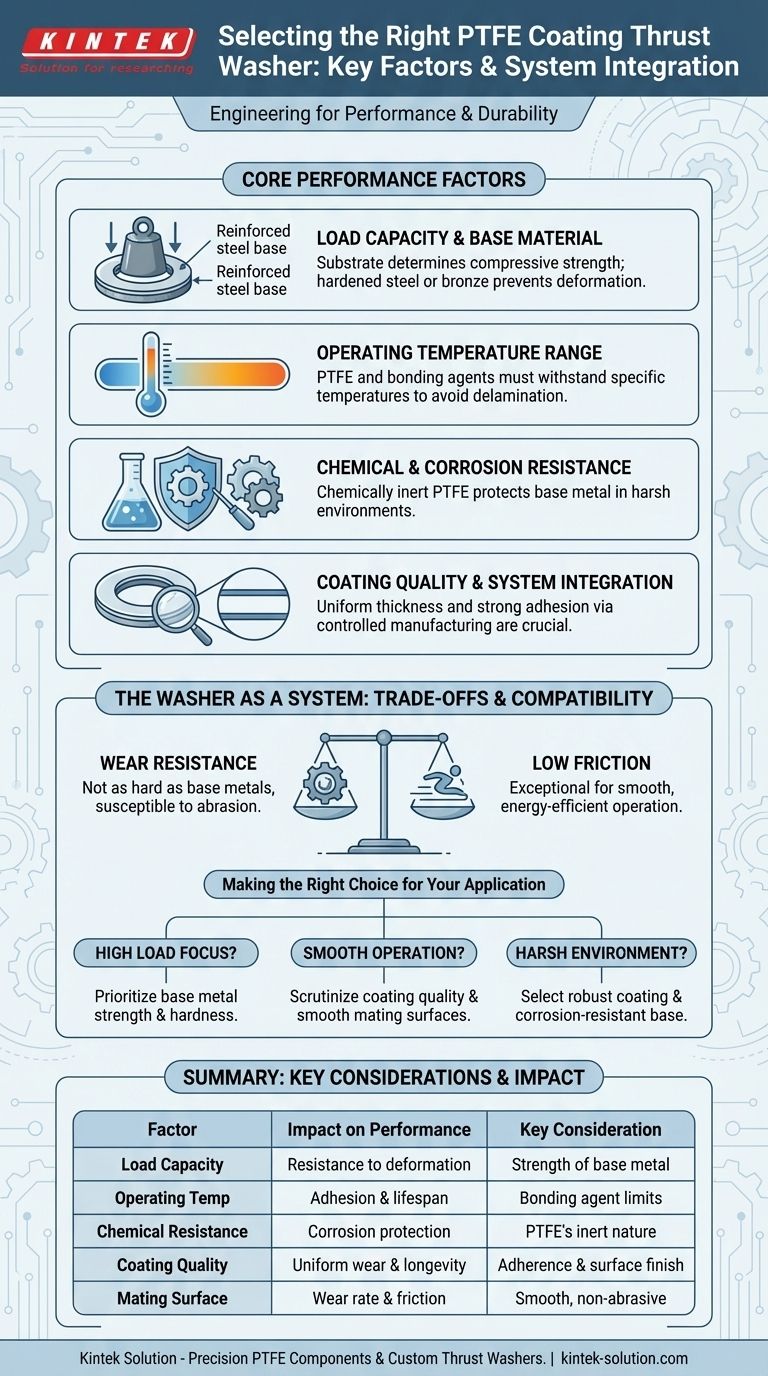

Core Performance Factors Explained

To make an informed decision, you must understand how each primary characteristic impacts the washer's function and lifespan.

Load Capacity and Base Material

PTFE itself is a relatively soft material. The washer's ability to withstand compressive force, or load capacity, comes from the underlying substrate, which is typically a metal like hardened steel or bronze. A robust base material is essential to prevent deformation under load.

Coefficient of Friction

The primary benefit of a PTFE coating is its extremely low coefficient of friction. This quality reduces the energy required for rotational movement, resulting in smoother, more efficient, and quieter operation.

Operating Temperature

PTFE is known for its high-temperature resistance. However, the entire washer assembly, including the base metal and the bonding agents used to adhere the coating, has a specific operating temperature range. Exceeding this range can lead to coating delamination or failure.

Chemical and Corrosion Resistance

PTFE is chemically inert, making it an excellent choice for applications involving corrosive fluids or harsh chemicals. This property is critical in industries like chemical processing or marine applications, where it provides a protective barrier for the base metal.

The Coating and System Integration

The quality of the PTFE layer and its interaction with adjacent parts are just as important as the material's inherent properties.

Coating Thickness and Uniformity

A consistent and uniform coating thickness is crucial for predictable performance. A coating that is too thin may wear prematurely, while one that is too thick or uneven can flake off or create dimensional tolerance issues.

The Manufacturing Process

The manufacturing process is a critical, often overlooked factor. Proper surface preparation of the base metal and a controlled curing process are required to ensure the PTFE coating adheres strongly. A poorly applied coating will fail quickly under operational stress.

Compatibility with Mating Surfaces

The surface finish of the components rotating against the washer has a direct impact on its lifespan. A rough or abrasive mating surface will act like sandpaper, rapidly wearing away the PTFE coating and negating its benefits.

Understanding the Trade-offs

Selecting the right component always involves balancing competing priorities. Being aware of the inherent trade-offs is key to avoiding common failures.

Wear Resistance vs. Low Friction

While PTFE offers exceptional low-friction properties, it is not as wear-resistant as harder materials. In environments with abrasive particles or under very high contact pressure, the coating can wear away. The design must protect the washer from these conditions.

The Washer as a System

Focusing only on the PTFE coating is a frequent mistake. A superior coating applied to an inappropriate base material—one that is too soft for the load or susceptible to corrosion in the operating environment—will result in a premature failure of the entire assembly.

Finite Lifespan

No coating lasts forever. The lifespan of a PTFE-coated washer is determined by the load, speed, temperature, and environmental conditions of the application. You must account for this wear and plan for eventual replacement as part of your design or maintenance schedule.

Making the Right Choice for Your Application

Use your primary goal to guide your selection criteria.

- If your primary focus is high load capacity: Prioritize the base metal's strength and hardness to prevent mechanical deformation.

- If your primary focus is smooth, low-friction operation: Scrutinize the quality of the PTFE coating and ensure mating surfaces have a very smooth finish.

- If your primary focus is longevity in a harsh environment: Select for a washer with a robust, well-adhered coating and a corrosion-resistant base material.

Ultimately, a successful selection aligns the entire washer system with the specific mechanical and environmental stresses of your design.

Summary Table:

| Factor | Impact on Performance | Key Consideration |

|---|---|---|

| Load Capacity | Determines resistance to deformation | Strength of base metal (e.g., hardened steel) |

| Operating Temperature | Affects coating adhesion and lifespan | Must not exceed bonding agent limits |

| Chemical Resistance | Protects against corrosion in harsh environments | PTFE's inert nature provides a barrier |

| Coating Quality | Ensures uniform wear and longevity | Adherence to base metal and surface finish |

| Mating Surface | Influences wear rate and friction | Smooth, non-abrasive surfaces recommended |

Need a PTFE thrust washer that perfectly matches your application's demands? At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom thrust washers for semiconductor, medical, laboratory, and industrial use. Our expertise ensures superior coating adhesion, precise load handling, and compatibility with your specific operational environment—from prototypes to high-volume orders. Contact us today to discuss your requirements and enhance your system's efficiency and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech