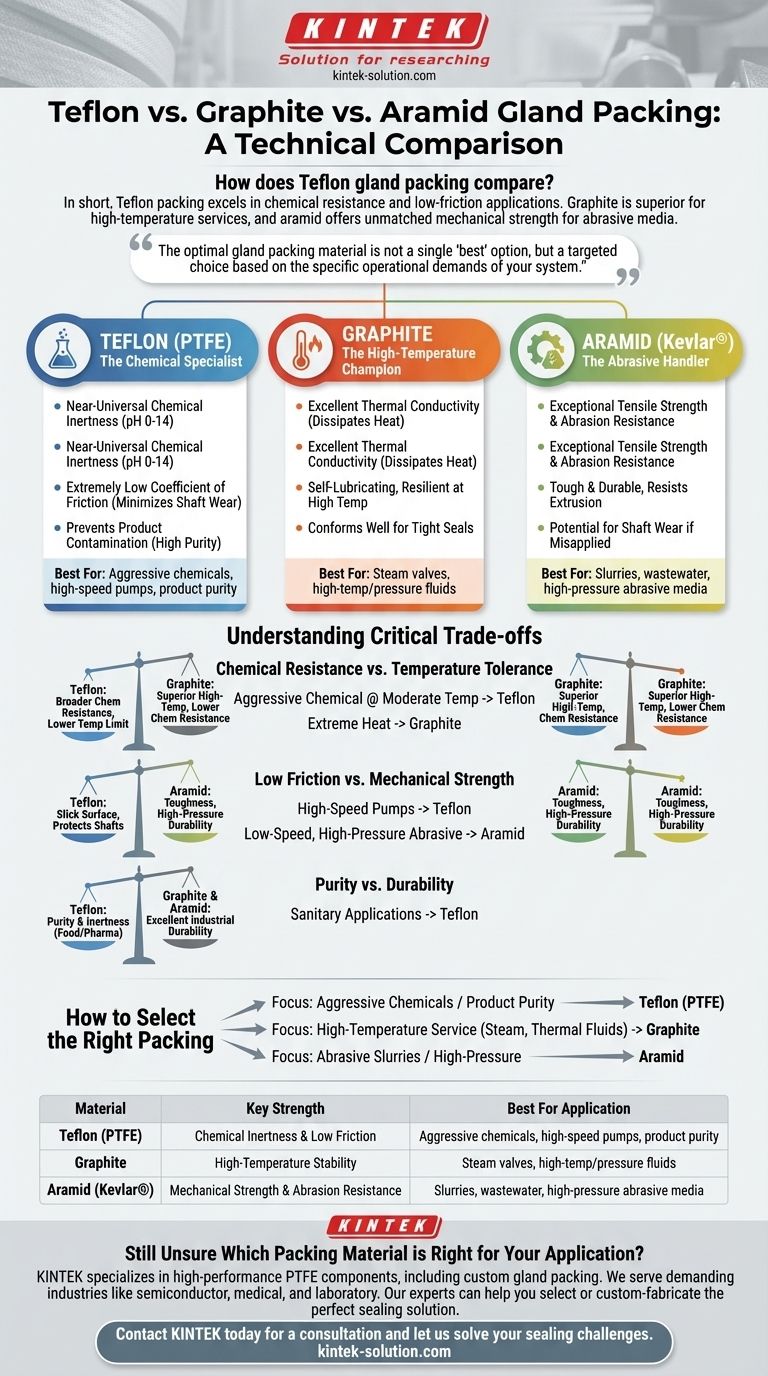

In short, Teflon packing excels in chemical resistance and low-friction applications. While graphite is superior for high-temperature services and aramid offers unmatched mechanical strength for abrasive media, Teflon (PTFE) is the default choice for sealing against aggressive chemicals, preventing product contamination, and minimizing wear on equipment shafts.

The optimal gland packing material is not a single "best" option, but a targeted choice based on the specific operational demands of your system. The decision hinges on a clear understanding of the trade-offs between chemical compatibility, temperature limits, and mechanical durability.

A Breakdown of Core Gland Packing Materials

To select the right material, you must understand the distinct strengths and weaknesses inherent to each option. Each excels in a different operational environment.

Teflon (PTFE): The Chemical Specialist

Teflon, or Polytetrafluoroethylene (PTFE), is renowned for its near-universal chemical inertness. It can handle a full pH range (0-14) and is unaffected by most aggressive solvents, acids, and caustics.

Its extremely low coefficient of friction is a critical advantage. This property minimizes drag on rotating shafts, reducing energy consumption and, most importantly, preventing shaft wear and scoring over time.

Graphite: The High-Temperature Champion

Graphite packing is the definitive choice for high-temperature and high-pressure applications, such as steam valves and high-temperature fluid pumps. It offers excellent thermal conductivity, which helps dissipate heat away from the shaft and stuffing box.

This material is also self-lubricating and remains resilient at temperatures where Teflon would fail. It conforms well to sealing surfaces, ensuring a tight seal even under thermal cycling.

Aramid (Kevlar®): The Abrasive Handler

Aramid fiber packing is prized for its exceptional tensile strength and abrasion resistance. It is incredibly tough and durable, making it ideal for sealing applications involving slurries, wastewater, or other fluids containing abrasive particles.

This mechanical strength allows it to withstand high pressures without extruding, but its toughness can also be a liability, potentially causing shaft wear if not applied and monitored correctly.

Understanding the Critical Trade-offs

Choosing a packing material always involves balancing competing properties. Understanding these compromises is key to avoiding premature failure.

Chemical Resistance vs. Temperature Tolerance

Teflon offers the broadest chemical resistance, but its temperature limit is generally lower than graphite's. If you are sealing an aggressive chemical at a moderate temperature, Teflon is the clear choice. If the primary challenge is extreme heat, graphite is superior.

Low Friction vs. Mechanical Strength

Teflon's slick surface protects equipment, making it ideal for high-speed pumps where minimizing shaft wear is paramount. In contrast, aramid's toughness is necessary for low-speed, high-pressure applications with abrasive media, where a less durable material would be quickly destroyed.

Purity vs. Durability

In industries like food processing, pharmaceuticals, or electronics, Teflon's purity and inertness are non-negotiable to prevent product contamination. While graphite and aramid are excellent industrial materials, they are not typically suited for these sanitary applications.

How to Select the Right Packing for Your Application

Base your decision on the single most demanding aspect of your operational environment.

- If your primary focus is aggressive chemicals or product purity: Teflon (PTFE) packing is almost always the correct choice due to its unmatched chemical inertness.

- If your primary focus is high-temperature service (e.g., steam, thermal fluids): Graphite packing provides the essential thermal stability that other materials lack.

- If your primary focus is handling abrasive slurries or high-pressure conditions: Aramid packing delivers the mechanical strength and durability required to resist wear and extrusion.

By aligning the material's core strengths with your operational demands, you ensure reliable sealing, protect your equipment, and achieve long-term performance.

Summary Table:

| Material | Key Strength | Best For Application |

|---|---|---|

| Teflon (PTFE) | Chemical Inertness & Low Friction | Aggressive chemicals, high-speed pumps, product purity |

| Graphite | High-Temperature Stability | Steam valves, high-temp/pressure fluids |

| Aramid (e.g., Kevlar®) | Mechanical Strength & Abrasion Resistance | Slurries, wastewater, high-pressure abrasive media |

Still Unsure Which Packing Material is Right for Your Application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing, seals, liners, and labware. We serve demanding industries like semiconductor, medical, and laboratory, where precision and material compatibility are critical.

Our experts can help you select or custom-fabricate the perfect sealing solution—from prototypes to high-volume orders—ensuring optimal performance, equipment protection, and cost-efficiency.

Contact KINTEK today for a consultation and let us solve your sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation