When selecting a PTFE rotary shaft seal, you are not choosing a single product but configuring a solution. The primary configurations available involve the lip design (hydrodynamic, plain, or multi-lip), the shell construction (machined for low volumes or pressed for high volumes), and the material composition, which can range from virgin PTFE to various filled grades for enhanced performance.

The core principle of PTFE seal configuration is that every element—from the lip geometry to the specific filler material—is a variable that can be adjusted to meet the precise demands of your application's speed, pressure, temperature, and chemical environment.

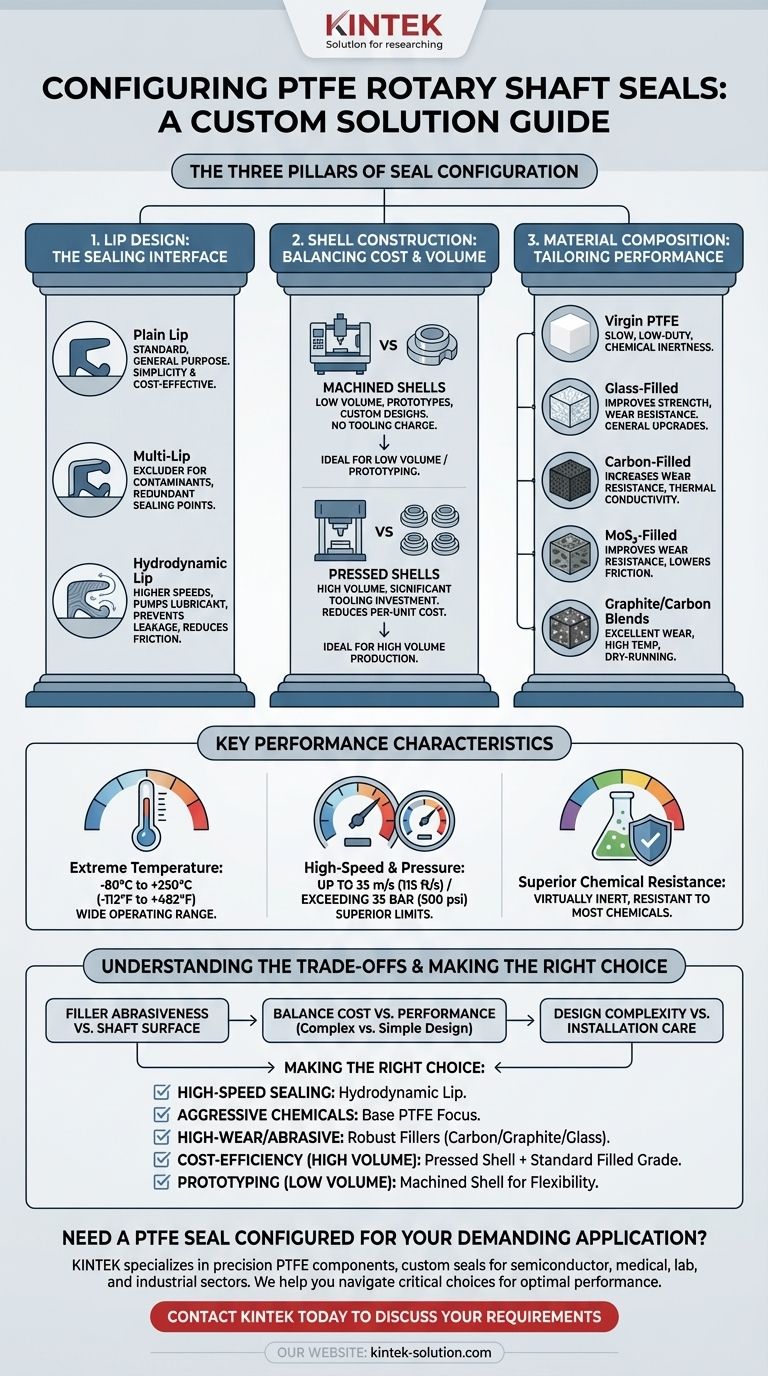

The Three Pillars of Seal Configuration

Understanding how to specify a PTFE seal begins with three fundamental areas of customization. Each pillar directly impacts the seal's performance, durability, and cost.

H3: Lip Design: The Sealing Interface

The lip is the most critical component for sealing effectiveness.

- Plain Lip: This is a standard design suitable for general-purpose, low-duty applications where simplicity and cost are key factors.

- Multi-Lip: These designs incorporate secondary lips, often to act as an excluder for external contaminants or to provide redundant sealing points in critical applications.

- Hydrodynamic Lip: For higher speeds, these seals feature subtle patterns on the lip or running surface. These patterns use the shaft's rotation to pump a small amount of lubricant back towards the system, preventing leakage and reducing friction.

H3: Shell Construction: Balancing Cost and Volume

The method used to create the seal's metal casing is a choice between upfront and per-unit cost.

- Machined Shells: These are produced from solid metal stock without requiring dedicated tooling. This makes them ideal for prototypes, custom designs, or low-volume production runs where avoiding a high tooling charge is paramount.

- Pressed Shells: For high-volume production, shells are stamped or "pressed" into shape using a die. While this involves a significant initial tooling investment, it dramatically reduces the cost of each individual seal.

H3: Material Composition: Tailoring Performance with Fillers

Virgin PTFE is rarely the optimal choice for demanding applications. Fillers are blended into the base PTFE to enhance specific mechanical properties.

- Virgin PTFE: Best for slow, low-duty use where chemical inertness is the primary concern.

- Glass-Filled: Significantly improves strength and wear resistance, making it a common choice for general-purpose upgrades.

- Carbon-Filled: Increases wear resistance and thermal conductivity without significantly raising friction.

- MoS₂ (Molybdenum Disulfide) Filled: Added to improve wear resistance and lower friction, especially in higher-duty applications. It can be combined with glass or carbon.

- Graphite/Carbon Blends: Offer excellent wear resistance, high-temperature performance, and good dry-running capabilities.

Key Performance Characteristics

These configuration choices enable PTFE seals to operate in environments where traditional elastomeric seals would fail.

H3: Extreme Temperature Tolerance

PTFE seals maintain their integrity and performance across an exceptionally wide temperature range, typically from -80°C to +250°C (-112°F to +482°F), with some specialized grades extending this even further.

H3: High-Speed and High-Pressure Capability

Properly configured PTFE seals can handle surface speeds up to 35 m/s (115 ft/s) and pressures exceeding 35 BAR (500 psi), far surpassing the limits of many other seal types.

H3: Superior Chemical Resistance

PTFE is virtually inert, making it resistant to almost all industrial chemicals and lubricants. The choice of filler must also be considered for full compatibility.

Understanding the Trade-offs

Selecting the right configuration requires balancing competing priorities. An enhancement in one area can introduce a limitation in another.

H3: Filler Abrasiveness

While fillers like glass significantly improve a seal's wear resistance, they can be more abrasive to the mating shaft surface. This requires careful consideration of shaft hardness and surface finish. A blend like Glass MoS₂ is often used to mitigate this effect.

H3: Cost vs. Performance

A highly customized seal with advanced fillers, a hydrodynamic lip, and a machined shell for a custom size will carry a higher cost. This investment is justified only when the application's demands for reliability and performance warrant it.

H3: Design Complexity and Installation

Multi-lip designs or seals integrated with springs are more complex to manufacture and may require more care during installation to ensure all sealing elements are correctly seated and undamaged.

Making the Right Choice for Your Application

Your final configuration should be dictated by your single most critical performance requirement.

- If your primary focus is high-speed sealing: A hydrodynamic lip design is essential to prevent leakage and manage frictional heat.

- If your primary focus is aggressive chemical environments: Prioritize the base PTFE material and ensure any fillers used are also fully compatible.

- If your primary focus is high-wear or abrasive media: Select a seal with a robust filler like carbon, graphite, or glass.

- If your primary focus is cost-efficiency for high-volume production: A pressed shell design combined with a suitable standard filled grade will offer the lowest per-unit cost.

- If your primary focus is prototyping or low-volume production: A machined shell avoids high initial tooling costs and offers maximum design flexibility.

Ultimately, configuring the right PTFE seal is about precisely matching its material and design to the demands of your specific operating environment.

Summary Table:

| Configuration Pillar | Key Options | Primary Application Benefit |

|---|---|---|

| Lip Design | Plain, Multi-lip, Hydrodynamic | Controls sealing effectiveness, friction, and speed capability |

| Shell Construction | Machined, Pressed | Balances upfront cost (prototypes) vs. per-unit cost (high volume) |

| Material Composition | Virgin PTFE, Glass-filled, Carbon-filled, MoS₂-filled | Tailors wear resistance, strength, and chemical compatibility |

Need a PTFE Seal Configured for Your Demanding Application?

KINTEK specializes in precision PTFE components, including custom rotary shaft seals for the semiconductor, medical, laboratory, and industrial sectors. We help you navigate the critical choices in lip design, shell construction, and material fillers to achieve optimal performance in extreme temperatures (up to 250°C), high speeds (up to 35 m/s), and aggressive chemical environments.

Whether you require a prototype or a high-volume order, our expertise ensures a perfect match for your operational demands. Contact KINTEK today to discuss your specific requirements and get a solution tailored for reliability and cost-efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability