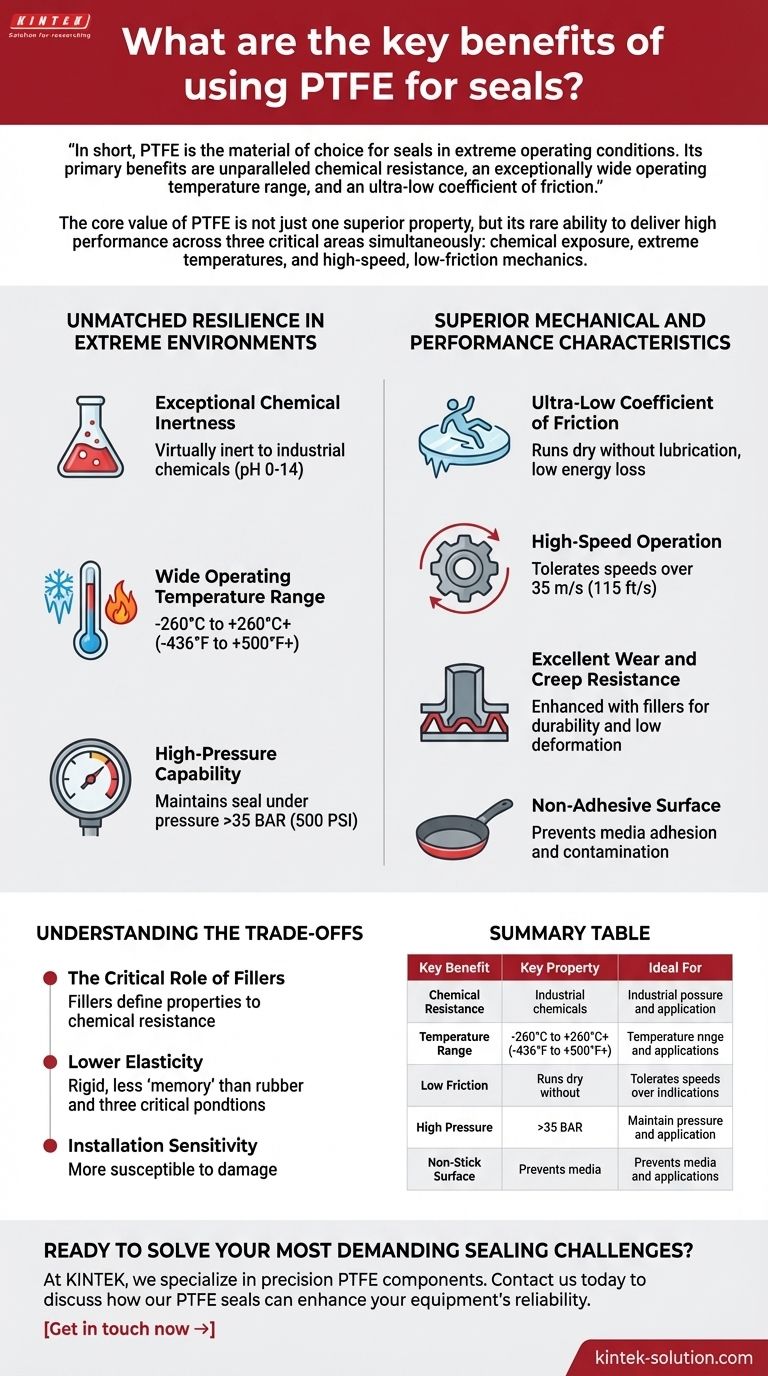

In short, PTFE is the material of choice for seals in extreme operating conditions. Its primary benefits are unparalleled chemical resistance, an exceptionally wide operating temperature range, and an ultra-low coefficient of friction. This unique combination allows PTFE seals to provide reliable, long-lasting performance where conventional materials would quickly degrade and fail.

The core value of PTFE is not just one superior property, but its rare ability to deliver high performance across three critical areas simultaneously: chemical exposure, extreme temperatures, and high-speed, low-friction mechanics. This makes it a problem-solver for the most demanding sealing applications.

Unmatched Resilience in Extreme Environments

The fundamental advantage of PTFE is its ability to maintain integrity when exposed to conditions that would destroy most other polymers. This resilience is key to its use in critical industrial, aerospace, and chemical processing applications.

### Exceptional Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, acids, and bases. This makes it an essential material in industries like pharmaceuticals, chemical manufacturing, and semiconductor production where seal failure due to chemical attack is a primary concern.

It can reliably handle fluids with a pH range from 0 to 14, ensuring a stable seal regardless of the process media.

### Wide Operating Temperature Range

PTFE seals function effectively across an enormous temperature spectrum, from cryogenic lows of -260°C (-436°F) up to high-heat applications of +260°C (+500°F) or more.

This thermal stability allows it to be used in everything from aerospace systems to automotive engines and oil and gas equipment, where seals experience drastic temperature fluctuations without losing their sealing capability.

### High-Pressure Capability

Engineered PTFE seals are designed to maintain a tight seal under significant pressure, often exceeding 35 BAR (500 PSI). This robust performance is critical in hydraulic systems and other high-pressure industrial processes where leaks are unacceptable.

Superior Mechanical and Performance Characteristics

Beyond its environmental resistance, PTFE's mechanical properties directly contribute to higher efficiency, greater reliability, and a longer service life for the equipment it's installed in.

### Ultra-Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" means less energy is lost to friction, improving overall system efficiency.

Crucially, this property allows PTFE seals to run dry without lubrication, reducing wear and tear in applications where lubricants are undesirable or impossible to use.

### High-Speed Operation

The combination of low friction and high-temperature resistance enables PTFE seals to perform reliably in high-speed rotating and reciprocating applications, tolerating surface speeds over 35 m/s (115 ft/s).

### Excellent Wear and Creep Resistance

While pure PTFE can be soft, it is often blended with fillers like carbon, glass, or bronze. These compounds significantly enhance its resistance to wear and creep (the tendency to deform under constant pressure), making it highly durable for dynamic applications.

### Non-Adhesive Surface

The non-stick surface of PTFE prevents process media from adhering to the seal. This ensures consistent performance over time and prevents contamination or buildup that could compromise the seal.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the practical considerations and potential challenges of working with PTFE.

### The Critical Role of Fillers

The specific performance characteristics of a PTFE seal are highly dependent on the filler material used. A seal designed for wear resistance (e.g., carbon-filled) will have different properties than one designed for FDA compliance. Understanding your application's specific need is crucial to selecting the right PTFE compound.

### Lower Elasticity

Compared to rubber elastomers, PTFE is a much more rigid material. It has less "memory" and elasticity, meaning it will not rebound to its original shape as readily. This requires more precise engineering of both the seal and the housing it sits in.

### Installation Sensitivity

Because of its lower elasticity, PTFE seals can be more susceptible to damage during installation if not handled carefully. Unlike a flexible rubber O-ring, a PTFE seal that is scratched or gouged may not seal properly.

Making the Right Choice for Your Application

Selecting PTFE is a decision to prioritize performance and long-term reliability in demanding environments.

- If your primary focus is aggressive media or chemicals: PTFE's near-universal chemical inertness is its defining advantage, ensuring seal integrity against corrosion.

- If your primary focus is extreme temperatures or high pressure: Its stability across a wide thermal and pressure range ensures reliability where elastomers would become brittle or fail.

- If your primary focus is high-speed or low-friction performance: PTFE's low coefficient of friction minimizes energy loss and wear, even in dry-running conditions.

- If your primary focus is long-term reliability and reduced maintenance: The combination of durability and environmental resistance leads to a significantly longer service life and a lower total cost of ownership.

Ultimately, choosing PTFE is an investment in operational certainty for your most mission-critical applications.

Summary Table:

| Key Benefit | Key Property | Ideal For |

|---|---|---|

| Chemical Resistance | Virtually inert to all industrial chemicals | Chemical processing, pharmaceuticals, semiconductor |

| Temperature Range | -260°C to +260°C+ | Aerospace, automotive, oil & gas |

| Low Friction | Lowest coefficient of friction | High-speed applications, dry-running systems |

| High Pressure | Capable of exceeding 35 BAR (500 PSI) | Hydraulic systems, industrial processes |

| Non-Stick Surface | Prevents media adhesion | Contamination-sensitive applications |

Ready to solve your most demanding sealing challenges?

At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact PTFE solution your application requires.

Contact us today to discuss how our PTFE seals can enhance your equipment's reliability, efficiency, and service life in extreme conditions. Get in touch now →

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In which industries are PTFE sheets commonly used? Key Applications for Non-Stick & Heat-Resistant Materials

- What types of chemical substances can PTFE bushings withstand? Ensure Reliability in Aggressive Environments

- What are critical installation practices for PTFE O-rings? Avoid Leaks and Ensure a Perfect Seal

- What solutions exist for the cold flow problem in PTFE gaskets? Prevent Leaks with Advanced Materials & Installation

- What materials are used in spring energized Teflon seals? A Guide to PTFE Jackets & Metal Springs

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction

- What are the key features of PTFE envelope gaskets? Unmatched Chemical Resistance & Durability

- What industries commonly use PTFE gaskets? Essential Sealing Solutions for Demanding Applications