At their core, PTFE envelope gaskets are composite seals designed to offer the exceptional chemical resistance of PTFE (Polytetrafluoroethylene) combined with the mechanical strength and resilience of a more traditional gasket material. Key features include near-universal chemical inertness, a wide operating temperature range from cryogenic levels up to 260°C (500°F), and a non-contaminating, non-stick surface.

The fundamental advantage of a PTFE envelope gasket is its ability to provide a chemically pure and inert sealing surface (the PTFE "envelope") while relying on a separate core material to deliver the mechanical compression and recovery needed for a durable, long-lasting seal.

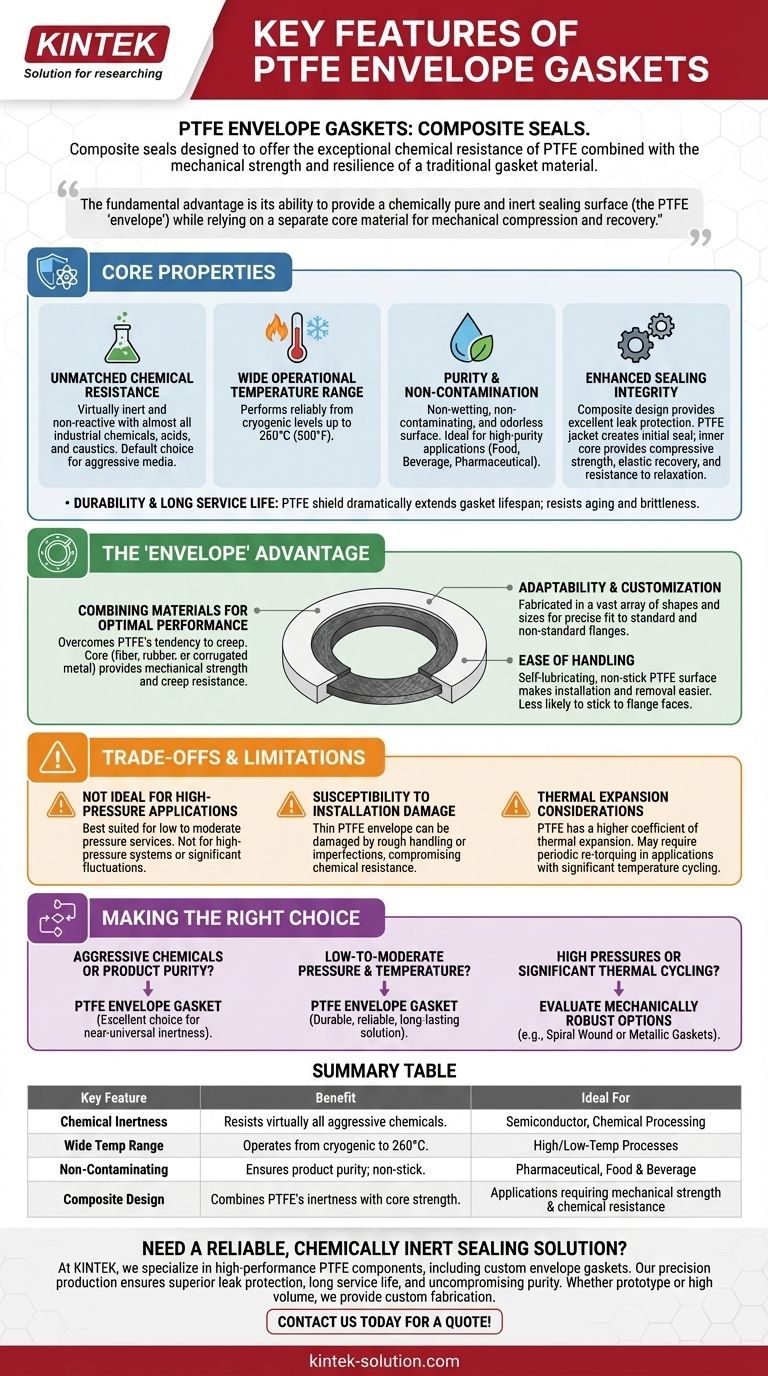

The Core Properties of PTFE Envelope Gaskets

To understand where these gaskets excel, we must analyze their distinct characteristics. The design leverages the best properties of multiple materials.

Unmatched Chemical Resistance

PTFE is virtually inert and non-reactive with almost all industrial chemicals, acids, and caustics. This makes it the default choice for sealing flanges that handle aggressive or corrosive media where other elastomers or materials would quickly degrade.

Wide Operational Temperature Range

These gaskets perform reliably across an impressive thermal spectrum. They maintain their integrity and sealing capability in applications ranging from cryogenic lows to high temperatures of approximately 260°C (500°F).

Purity and Non-Contamination

The PTFE surface is non-wetting, non-contaminating, and odorless. This prevents the process media from adhering to the gasket, which simplifies cleaning and makes these gaskets ideal for high-purity applications in the food, beverage, and pharmaceutical industries.

Enhanced Sealing Integrity

The composite design provides excellent leak protection. The flexible, conformable PTFE jacket creates the initial seal, while the inner core material provides the compressive strength to maintain that seal over time, exhibiting good elastic recovery and resistance to relaxation.

Durability and Long Service Life

By shielding the core material from chemical attack, the PTFE envelope dramatically extends the gasket's lifespan. The material is also known for its slow aging characteristics, resisting brittleness even in harsh operational conditions.

The "Envelope" Advantage: Design and Function

The term "envelope" refers to the gasket's construction. A thin jacket or "envelope" of PTFE encloses a more mechanically robust insert material.

Combining Materials for Optimal Performance

This design overcomes the primary weakness of pure PTFE—its tendency to creep or cold flow under pressure. The inner core, often made of a non-asbestos fiber, rubber, or corrugated metal, provides the mechanical strength and creep resistance that solid PTFE lacks.

Adaptability and Customization

PTFE envelope gaskets can be fabricated in a vast array of shapes and sizes to fit standard and non-standard flanges. This adaptability ensures a precise fit for specific application requirements, maximizing sealing efficiency.

Ease of Handling

The self-lubricating and non-stick properties of the PTFE surface make installation and removal significantly easier. The gasket is less likely to stick to flange faces, reducing the time and effort required for maintenance and replacement.

Understanding the Trade-offs and Limitations

No sealing solution is perfect for every scenario. An objective assessment requires understanding the limitations of PTFE envelope gaskets.

Not Ideal for High-Pressure Applications

While the core adds strength, these gaskets are typically best suited for low to moderate pressure services. In high-pressure systems, especially those with significant pressure fluctuations, a more robust design like a spiral wound gasket is often required.

Susceptibility to Installation Damage

The PTFE envelope is relatively thin and can be scratched or damaged by rough handling or imperfections on the flange surface. Any breach in the envelope exposes the core material to the process media, compromising the gasket's chemical resistance and leading to premature failure.

Thermal Expansion Considerations

PTFE has a higher coefficient of thermal expansion than the metals used in flanges. In applications with significant temperature cycling, this can require periodic re-torquing of flange bolts to maintain the proper sealing stress on the gasket.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its capabilities to your specific operational demands.

- If your primary focus is sealing aggressive chemicals or ensuring product purity: The PTFE envelope gasket is an excellent, often necessary, choice due to its near-universal inertness.

- If your application involves low-to-moderate pressure and temperature: This gasket provides a durable, reliable, and long-lasting sealing solution that is easy to maintain.

- If you are dealing with high pressures or significant thermal cycling: You should evaluate more mechanically robust options, such as spiral wound or metallic gaskets, which are better designed to handle those stresses.

Ultimately, choosing the right gasket is about understanding your exact environment and selecting the material designed to master it.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all aggressive chemicals and acids. | Semiconductor, Chemical Processing |

| Wide Temperature Range | Operates from cryogenic to 260°C (500°F). | High/Low-Temperature Processes |

| Non-Contaminating Surface | Ensures product purity; non-stick and easy to clean. | Pharmaceutical, Food & Beverage |

| Composite Design | Combines PTFE's inertness with a strong core for durability. | Applications requiring mechanical strength and chemical resistance |

Need a reliable, chemically inert sealing solution?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets designed for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets deliver superior leak protection, long service life, and uncompromising purity.

Whether you require a prototype or a high-volume order, we provide custom fabrication to meet your exact specifications. Contact us today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components