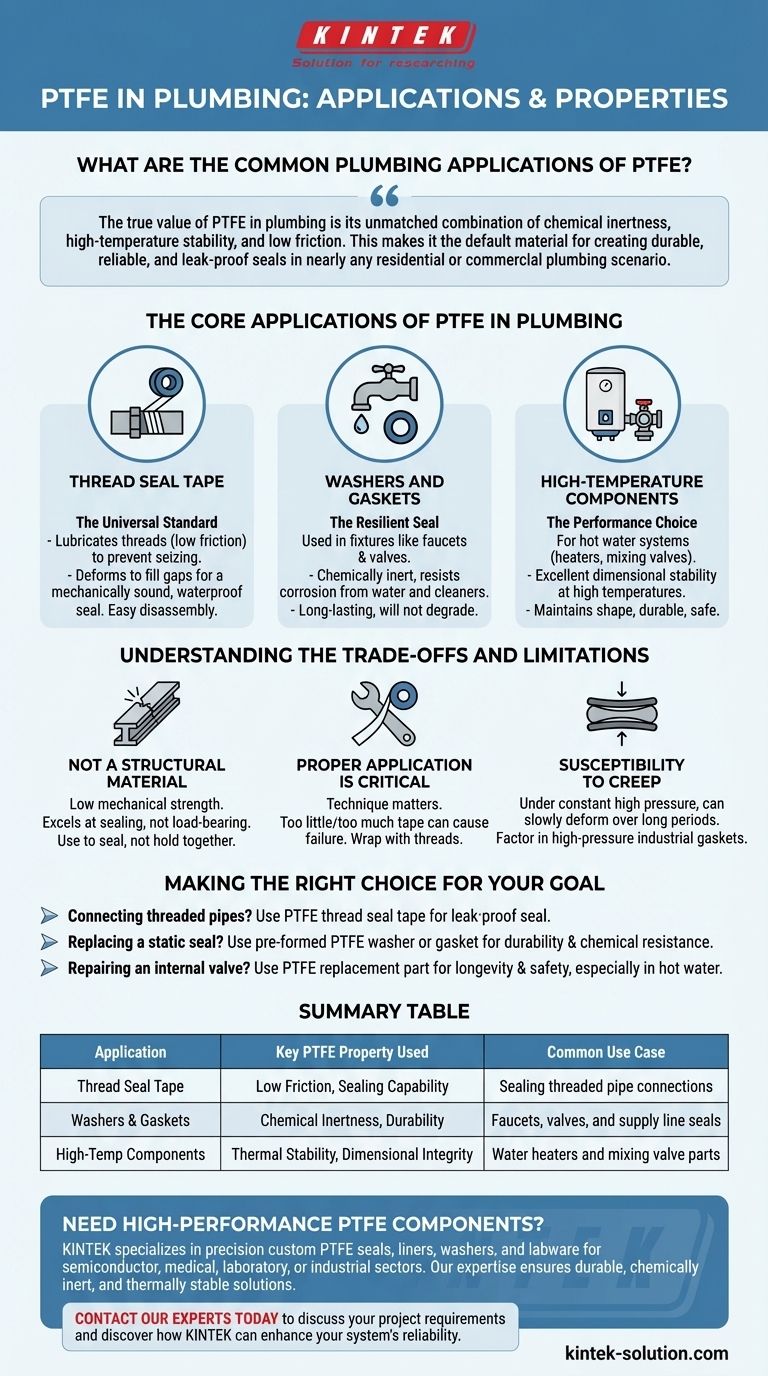

In the world of plumbing, Polytetrafluoroethylene (PTFE) is a cornerstone material used for three primary applications: creating leak-proof seals on threaded pipes with plumber's tape, serving as durable washers and gaskets in fittings, and manufacturing critical components for hot water systems. Its selection for these roles is not accidental but a direct result of its unique material properties.

The true value of PTFE in plumbing is its unmatched combination of chemical inertness, high-temperature stability, and low friction. This makes it the default material for creating durable, reliable, and leak-proof seals in nearly any residential or commercial plumbing scenario.

The Core Applications of PTFE in Plumbing

PTFE's versatility makes it a solution for several distinct but related challenges in fluid systems. Each application leverages a specific set of its inherent characteristics.

Thread Seal Tape: The Universal Standard

The most recognizable use of PTFE is plumber's tape. This thin, non-adhesive film is wrapped around the male threads of a pipe before it's screwed into a fitting.

Its function is twofold. First, it acts as a lubricant, leveraging PTFE's extremely low coefficient of friction to prevent threads from galling or seizing. This allows for a tighter, more secure connection.

Second, the soft tape deforms and fills the microscopic gaps between threads, creating a mechanically sound and waterproof seal that is flexible and easy to disassemble years later.

Washers and Gaskets: The Resilient Seal

PTFE is almost exclusively used for manufacturing washers, gaskets, and seals used within plumbing fixtures like faucets, valves, and flexible supply lines.

Here, its value comes from its chemical inertness. It will not break down or corrode when exposed to treated municipal water, common household cleaners, or temperature fluctuations.

This resilience ensures a long-lasting, reliable seal that won't degrade and cause leaks over time, unlike some rubber or fiber-based alternatives.

High-Temperature Components: The Performance Choice

For applications involving hot water, such as internal parts for water heaters or mixing valves, PTFE is the material of choice. This is due to its excellent dimensional stability at high temperatures.

While other plastics might soften, deform, or leach chemicals when exposed to continuous hot water, PTFE maintains its shape and integrity. This makes components like valve seats and linings made from PTFE exceptionally durable and safe for hot water systems.

Understanding the Trade-offs and Limitations

While PTFE is an exceptional material, its proper use requires understanding its limitations. It is not a universal solution for every engineering problem.

Not a Structural Material

PTFE has relatively low mechanical strength. It excels at sealing and reducing friction but should never be used as a primary structural or load-bearing component. Its purpose is to seal a joint, not to hold it together.

Proper Application is Critical

With plumber's tape, technique matters. Applying too little tape can fail to create a seal, while applying too much can crack the female fitting upon tightening. The tape must also be wrapped in the correct direction (with the threads) to avoid unwinding as the joint is assembled.

Susceptibility to Creep

Under constant, high pressure over a long period, PTFE can slowly deform, a phenomenon known as "creep." While not an issue for most standard plumbing jobs, it's a factor engineers consider when designing high-pressure industrial gaskets, where re-torquing may be required.

Making the Right Choice for Your Goal

Selecting the correct form of PTFE is straightforward when you align it with the specific plumbing task at hand.

- If your primary focus is connecting threaded pipes: Always use PTFE thread seal tape to lubricate the threads and guarantee a leak-proof seal.

- If your primary focus is replacing a static seal in a faucet or fitting: A pre-formed PTFE washer or gasket provides the best combination of durability and chemical resistance.

- If your primary focus is repairing an internal valve component: Ensure the replacement part, especially one in a hot water line, is made from PTFE for maximum longevity and safety.

Ultimately, PTFE's unique properties have made it an indispensable and trusted material for ensuring modern plumbing systems are both efficient and reliable.

Summary Table:

| Application | Key PTFE Property Used | Common Use Case |

|---|---|---|

| Thread Seal Tape | Low Friction, Sealing Capability | Sealing threaded pipe connections |

| Washers & Gaskets | Chemical Inertness, Durability | Faucets, valves, and supply line seals |

| High-Temp Components | Thermal Stability, Dimensional Integrity | Water heaters and mixing valve parts |

Need high-performance PTFE components for your plumbing or industrial applications?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, washers, and labware. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures durable, chemically inert, and thermally stable solutions tailored to your exact needs.

Contact our experts today to discuss your project requirements and discover how KINTEK can enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why are Teflon bushes suitable for food and pharmaceutical manufacturing? Ensuring Purity and Safety

- What quality standards are followed in the manufacturing of Teflon-encapsulated O-Rings? Ensure Compliance for Critical Applications

- What are typical applications of Teflon/PTFE machined parts? Key Uses in Aerospace, Medical & Chemical Processing

- How does the fiber structure of ePTFE gaskets provide mechanical compensation? Sealing Imperfect Flanges

- Why is a thin element design preferred for PTFE seals from a cost standpoint? Minimize Initial Cost & Maximize Long-Term Value

- What are PTFE compounds and how are they used? Enhance Performance for Demanding Applications

- What were the results of the PTFE wear plates trial in the die-casting industry? Boost Efficiency with Superior Wear Resistance

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems