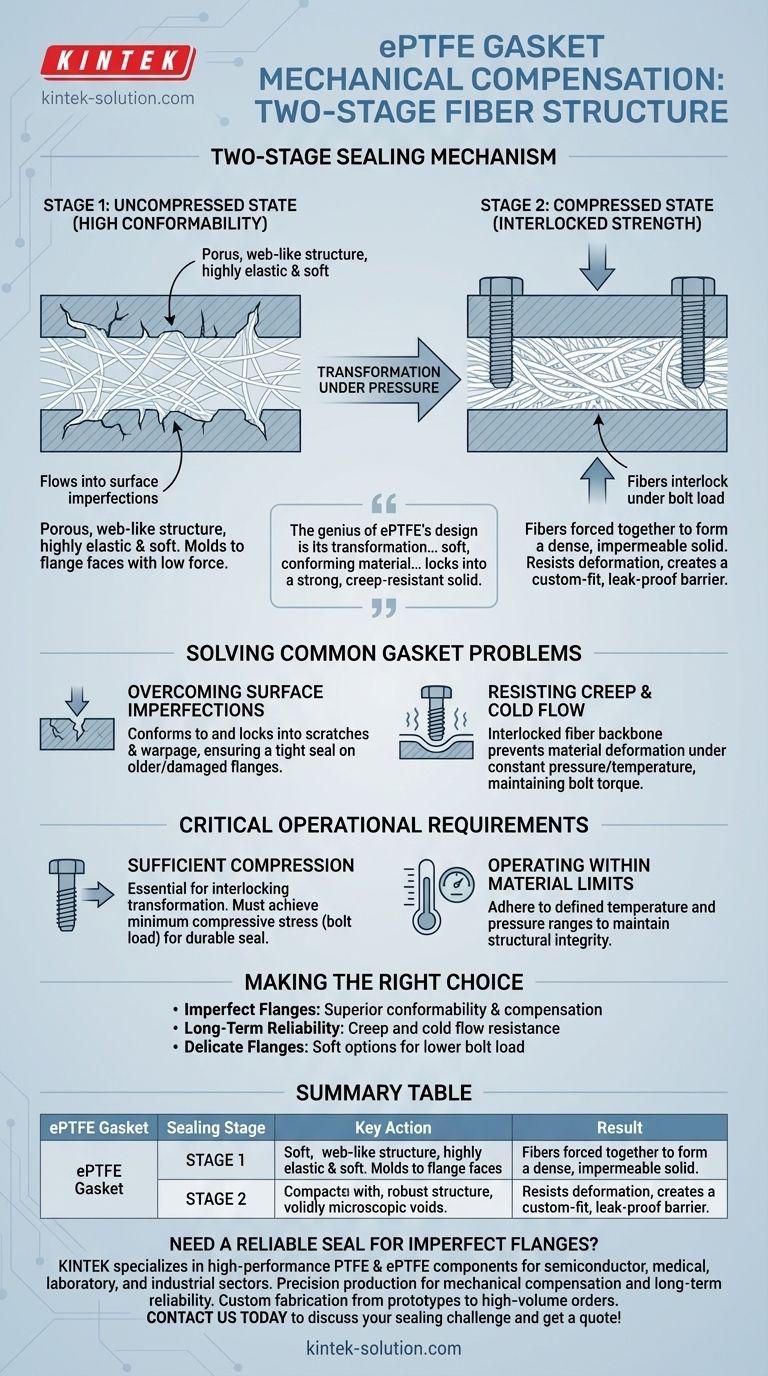

At its core, the fiber structure of an expanded Polytetrafluoroethylene (ePTFE) gasket provides mechanical compensation through a unique two-stage process. Initially, its fine, bidirectional fiber network is highly elastic and conformable, allowing it to easily fill surface imperfections. When compressed, these fibers interlock to form a solid, tough structure that resists further deformation and maintains a durable seal.

The genius of ePTFE's design is its transformation under pressure. It begins as a soft, conforming material to perfectly match a flange face, then locks into a strong, creep-resistant solid that maintains sealing integrity over time.

The Two-Stage Sealing Mechanism

The effectiveness of ePTFE hinges on how its internal structure behaves before and after compression. It is not simply a soft material; it is a highly engineered network of fibers and nodes.

Stage 1: The Uncompressed State (High Conformability)

Before compression, the ePTFE material consists of a multi-directional web of fine fibers. This structure is not a solid block but is full of microscopic voids.

This porous, web-like nature gives the gasket high elasticity and makes it exceptionally soft. It can be easily compressed with relatively low force, allowing it to flow into and fill the microscopic scratches, pits, and waviness present on virtually all industrial flange surfaces.

Stage 2: The Compressed State (Interlocked Strength)

As bolt load is applied, the voids within the structure collapse, and the individual fibers are forced together.

These fibers then interlock, creating a dense, robust, and impermeable material. This interlocked structure is incredibly strong and solid, losing the softness of its uncompressed state.

This transformation is what "compensates" for imperfections. The material first molds itself perfectly to the flange and then solidifies in that shape, creating a custom-fit, leak-proof barrier.

How This Structure Solves Common Gasket Problems

This unique mechanism directly addresses the most frequent causes of gasket failure, which is why ePTFE is valued in demanding applications.

Overcoming Surface Imperfections

Standard solid gaskets require nearly perfect, smooth flange surfaces to seal effectively. Any scratch or warpage can create a leak path.

The ePTFE structure, by first conforming and then locking, creates a perfect mirror image of the flange faces, including their flaws. This ensures a tight seal even on older, damaged, or slightly misaligned surfaces.

Resisting Creep and Cold Flow

Creep (or "cold flow") is a common failure mode for traditional PTFE materials. Under constant pressure and temperature, the material slowly deforms and flows out of the flange, causing a loss of bolt load and eventual leakage.

The interlocked fiber structure of ePTFE fundamentally prevents this. Once compressed, the fibers provide a structural backbone that resists the tendency to flow, ensuring the seal remains tight and the bolt torque is maintained over long periods.

Understanding the Trade-offs

While highly effective, understanding the operational requirements of ePTFE is crucial for success.

Sufficient Compression is Non-Negotiable

The transformation from elastic to interlocked is the key to the seal. This requires achieving a minimum compressive stress on the gasket.

If insufficient bolt load is applied, the fibers will not fully interlock, and the gasket may fail to create a durable, creep-resistant seal. Always follow the manufacturer's torque specifications.

Operating Within Material Limits

Like all materials, ePTFE has defined temperature and pressure limits. While its chemical resistance is exceptional, exceeding its design temperature can compromise the integrity of the fibrous structure.

Ensuring your application's parameters are well within the gasket's specified range is essential for long-term reliability.

Making the Right Choice for Your Application

Selecting a gasket depends entirely on the specific challenges of your flange connection.

- If your primary focus is sealing older or imperfect flanges: ePTFE is an ideal choice due to its superior ability to conform and compensate for surface damage.

- If your primary focus is long-term reliability in a critical system: The creep and cold flow resistance of ePTFE provides confidence that the seal will last.

- If you are dealing with a delicate flange that requires a seal with lower bolt load: Certain forms of soft, conformable ePTFE are specifically designed to create an effective seal under these conditions.

By understanding how ePTFE's internal fiber structure works, you can leverage its unique properties to create more reliable and durable sealed joints.

Summary Table:

| ePTFE Gasket Sealing Stage | Key Action | Result |

|---|---|---|

| Stage 1: Uncompressed | Fibers conform to surface | Fills scratches and pits for initial seal |

| Stage 2: Compressed | Fibers interlock under bolt load | Creates a strong, permanent, creep-resistant seal |

Need a reliable seal for imperfect flanges?

KINTEK specializes in manufacturing high-performance PTFE and ePTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets provide the mechanical compensation and long-term reliability your critical applications demand.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss your sealing challenge and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability