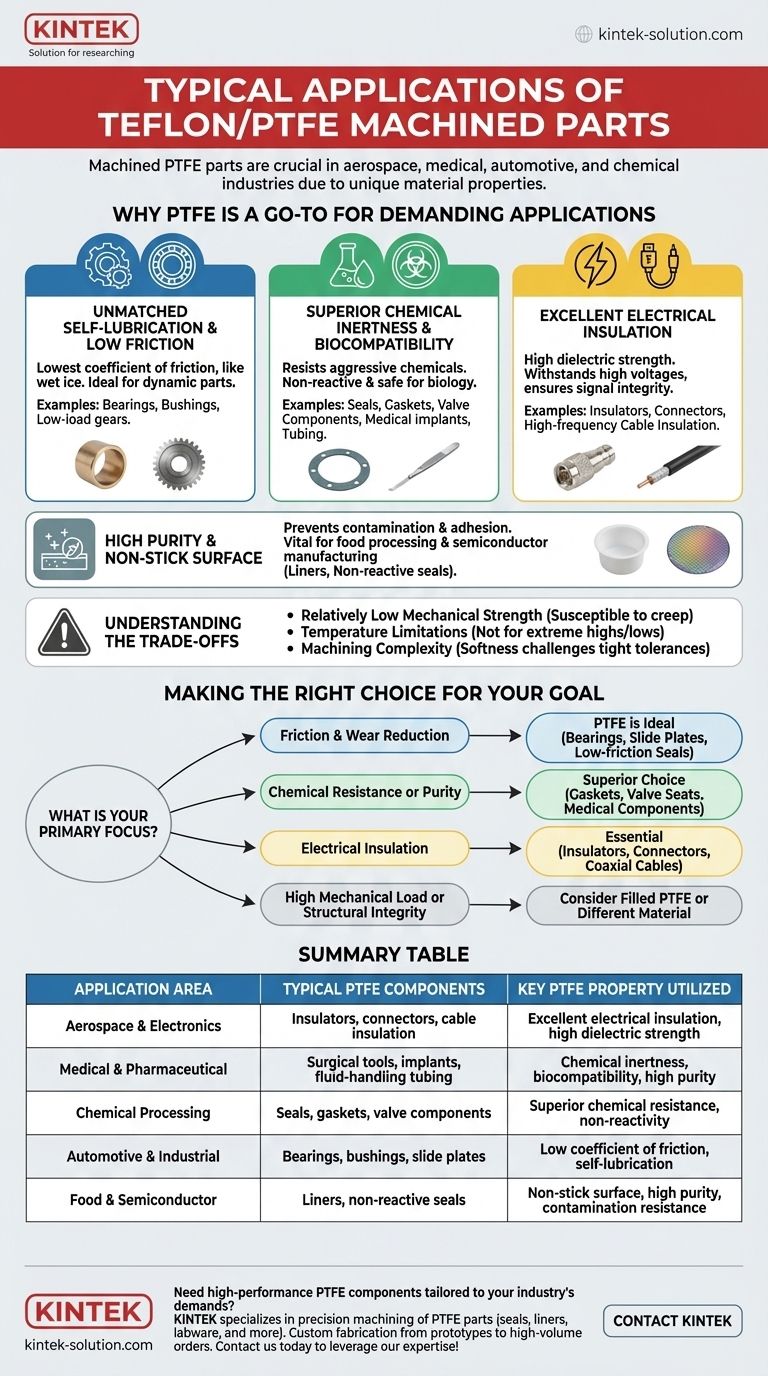

Machined Teflon (PTFE) parts are specified across a vast range of high-stakes industries due to a unique combination of material properties. Their most typical applications are found in aerospace, medical, automotive, and chemical processing for components like seals, bearings, insulators, and gaskets where extreme reliability is non-negotiable.

The widespread use of machined PTFE is not a coincidence; it is a direct result of its three defining characteristics: an exceptionally low coefficient of friction, near-total chemical inertness, and outstanding electrical insulation. Understanding these properties is the key to identifying its ideal application.

Why PTFE is a Go-To for Demanding Applications

The value of machined Teflon parts stems from a set of core strengths that solve specific engineering challenges better than most other polymers.

Unmatched Self-Lubrication and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent slipperiness is invaluable for dynamic parts.

This property makes it the material of choice for bearings, bushings, and low-load gears that must operate smoothly with minimal wear and without external lubrication.

Superior Chemical Inertness

PTFE is highly non-reactive and resists degradation from the most aggressive acids, bases, and solvents. It is also biocompatible, meaning it does not react with biological tissue.

This makes it essential for seals, gaskets, and valve components in chemical processing pipelines. In the medical field, its inertness is critical for surgical instruments, implants, and fluid-handling tubing.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This capability is crucial in the aerospace and electronics industries. It is widely used for high-frequency cable insulation, connectors, and standoff insulators where signal integrity and safety are paramount.

High Purity and Non-Stick Surface

The material is inherently pure and its non-stick surface prevents materials from adhering to it, which is vital for avoiding contamination.

This is why PTFE is common in food processing equipment for components like liners and non-reactive seals, as well as in semiconductor manufacturing where even microscopic contamination can ruin components.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. An objective evaluation requires acknowledging its limitations.

Relatively Low Mechanical Strength

Compared to other engineering plastics like PEEK or even metals, PTFE is a relatively soft material. It is susceptible to "creep" or cold flow, meaning it can deform over time under sustained pressure.

This makes it unsuitable for high-load structural applications. Its tensile strength and wear resistance are moderate unless enhanced with fillers like glass or carbon.

Temperature Limitations

While PTFE has a wide operating temperature range, it is not intended for extreme high-temperature environments where ceramics or high-performance metals would be required. It can also become brittle at cryogenic temperatures.

Machining Complexity

The softness that contributes to PTFE's excellent sealing properties can also make it challenging to machine to extremely tight tolerances. Achieving precision requires specialized tooling and expertise to manage heat and prevent part deformation.

Making the Right Choice for Your Goal

To leverage PTFE effectively, match its core strengths to the primary demand of your application.

- If your primary focus is reducing friction and wear: PTFE's self-lubricating nature is ideal for bearings, slide plates, and low-friction seals.

- If your primary focus is chemical resistance or purity: Its inertness makes it the superior choice for gaskets, valve seats, and components in medical, chemical, or food processing.

- If your primary focus is electrical insulation: Its high dielectric strength is essential for insulators, connectors, and high-frequency coaxial cables.

- If your primary focus is high mechanical load or structural integrity: You should consider either a filled grade of PTFE for improved strength or a different material entirely.

By understanding this balance of properties, you can confidently specify machined PTFE where its unique strengths will deliver maximum performance and reliability.

Summary Table:

| Application Area | Typical PTFE Components | Key PTFE Property Utilized |

|---|---|---|

| Aerospace & Electronics | Insulators, connectors, cable insulation | Excellent electrical insulation, high dielectric strength |

| Medical & Pharmaceutical | Surgical tools, implants, fluid-handling tubing | Chemical inertness, biocompatibility, high purity |

| Chemical Processing | Seals, gaskets, valve components | Superior chemical resistance, non-reactivity |

| Automotive & Industrial | Bearings, bushings, slide plates | Low coefficient of friction, self-lubrication |

| Food & Semiconductor | Liners, non-reactive seals | Non-stick surface, high purity, contamination resistance |

Need high-performance PTFE components tailored to your industry's demands? KINTEK specializes in precision machining of PTFE parts (seals, liners, labware, and more) for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring reliability in the most demanding environments. Contact us today to discuss your project and leverage our expertise in material science and precision production!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability