The manufacturing of Teflon-encapsulated O-rings is governed by specific, verifiable compliance standards designed for sensitive and demanding industries. Key standards include FDA compliance for food and drug contact and USP Class VI certification for medical and pharmaceutical applications. These are supported by rigorous quality assurance protocols, from raw material sourcing and traceability to final inspection of the finished product.

The core measure of quality for these components is not just general manufacturing excellence, but their documented adherence to specific regulatory standards. This verifiable compliance is what provides the necessary assurance for their use in critical food, medical, and chemical processing environments.

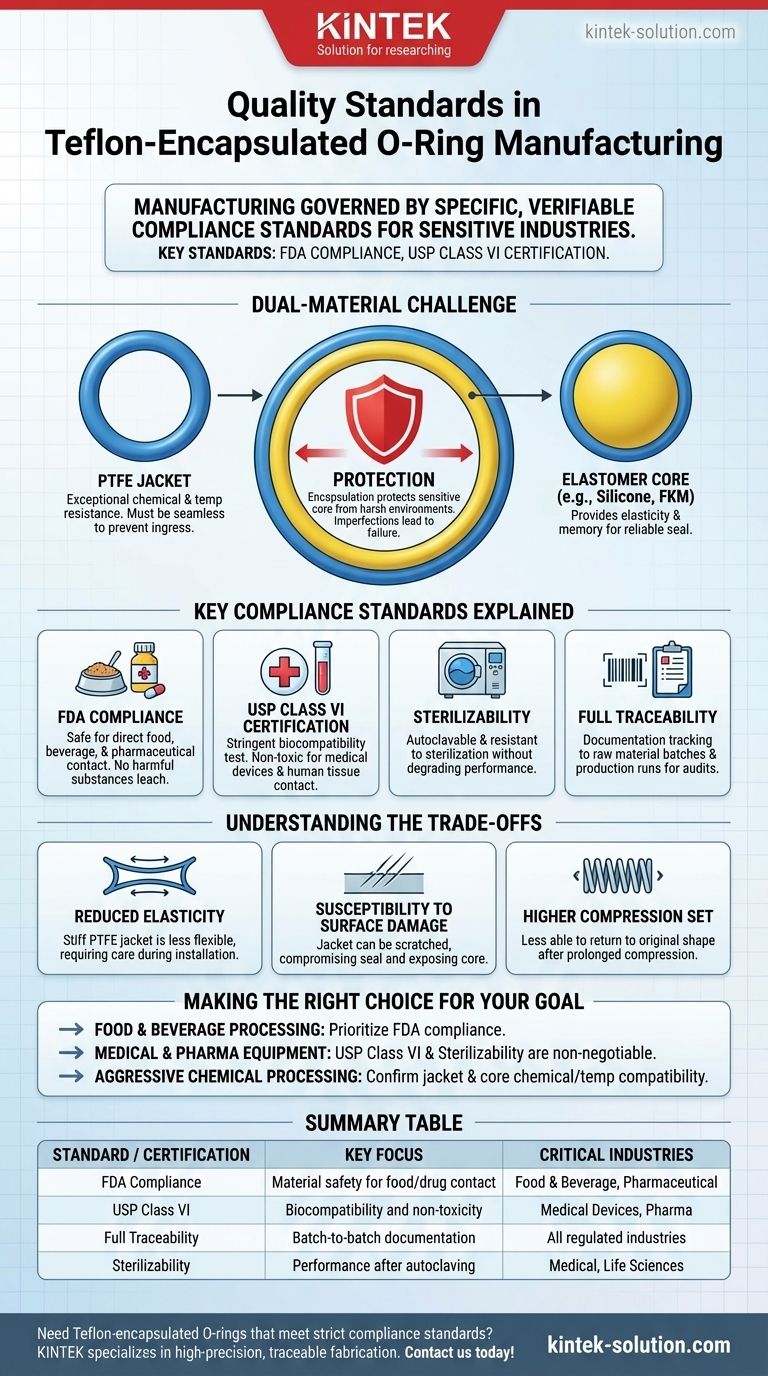

Why These Standards Are Critical: The Dual-Material Challenge

Teflon-encapsulated O-rings are composite seals, combining an outer jacket of chemically inert PTFE (Teflon) with a flexible, resilient inner core made of an elastomer like Silicone or FKM. This design creates unique manufacturing challenges that demand strict quality control.

The Role of the PTFE Jacket

The outer jacket provides exceptional resistance to chemicals and extreme temperatures. The quality process must ensure this layer is seamless, non-porous, and uniformly thick to prevent any chemical ingress.

The Function of the Elastomer Core

The inner core provides the elasticity and memory required for a reliable seal. The manufacturing process must preserve the core's mechanical properties without exposing it to damaging temperatures or chemicals.

Protecting the Core Material

The entire purpose of the encapsulation is to protect the sensitive elastomer core from harsh environments. Any crack, pinhole, or imperfection in the Teflon jacket represents a total failure of the component, making meticulous inspection essential.

Key Compliance Standards Explained

Beyond general process controls, specific certifications validate the O-ring's suitability for high-purity applications. These standards are the definitive benchmark of quality.

FDA Compliance

O-rings that are FDA compliant are made from materials deemed safe for direct contact with food, beverages, and pharmaceuticals. This standard ensures that no harmful substances will leach from the O-ring into the product.

USP Class VI Certification

The United States Pharmacopeia (USP) Class VI standard is one of the most stringent tests for biocompatibility. Materials must pass rigorous testing to ensure they are non-toxic and do not cause a reaction when in contact with human tissue, making this essential for medical devices and pharmaceutical equipment.

Sterilizability

For medical and life science applications, the ability to be sterilized is a critical quality attribute. These O-rings are manufactured to be autoclavable and resistant to common sterilization methods without degrading their sealing performance.

Full Traceability

Reputable manufacturing includes full traceability and documentation. This means every O-ring can be traced back to the specific raw material batches and production runs used in its creation, which is a critical requirement for regulatory compliance and quality audits.

Understanding the Trade-offs

While highly effective, the unique construction of encapsulated O-rings presents specific trade-offs that users must understand.

Reduced Elasticity

The stiff PTFE jacket makes these O-rings less flexible than standard all-elastomer O-rings. They have less "stretch" and require more care during installation to avoid over-stretching and damaging the jacket.

Susceptibility to Surface Damage

The Teflon jacket, while durable, can be scratched or nicked during installation. Any damage to this outer layer can create a leak path that compromises the seal and exposes the inner core to chemical attack.

Higher Compression Set

Encapsulated O-rings can sometimes exhibit a higher compression set, meaning they are less able to return to their original shape after being compressed for a long time. This requires careful gland design to ensure a persistent, effective seal.

Making the Right Choice for Your Goal

To ensure reliability, match the O-ring's documented standards to the specific needs of your environment.

- If your primary focus is food and beverage processing: Prioritize O-rings that are explicitly stated to be FDA compliant, with supporting documentation.

- If your primary focus is medical or pharmaceutical equipment: USP Class VI certification is non-negotiable, along with verified performance after your required sterilization methods.

- If your primary focus is aggressive chemical processing: Confirm the chemical compatibility of the PTFE jacket and ensure the elastomer core (e.g., FKM or Silicone) meets your application's temperature requirements.

Ultimately, selecting the correct encapsulated O-ring comes down to matching its documented compliance with the precise demands of your application.

Summary Table:

| Standard/Certification | Key Focus | Critical Industries |

|---|---|---|

| FDA Compliance | Material safety for food/drug contact | Food & Beverage, Pharmaceutical |

| USP Class VI | Biocompatibility and non-toxicity | Medical Devices, Pharma |

| Full Traceability | Batch-to-batch documentation and audit readiness | All regulated industries |

| Sterilizability | Performance after autoclaving/sterilization | Medical, Life Sciences |

Need Teflon-encapsulated O-rings that meet strict compliance standards?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom encapsulated O-rings for semiconductor, medical, laboratory, and industrial applications. Our rigorous quality assurance process ensures full traceability and compliance with FDA, USP Class VI, and other critical standards.

We provide custom fabrication from prototypes to high-volume orders, delivering the reliability your critical applications demand.

Contact us today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs