From a purely economic standpoint, a thin element design is preferred for PTFE seals because it uses the minimum amount of raw material required for the component. This reduction in material, combined with a simpler design geometry, directly lowers the upfront manufacturing cost of the seal.

While a thin design lowers the initial purchase price, the true cost advantage of PTFE seals is realized over the long term. Their inherent material properties significantly reduce maintenance, equipment wear, and costly operational downtime, delivering a lower total cost of ownership.

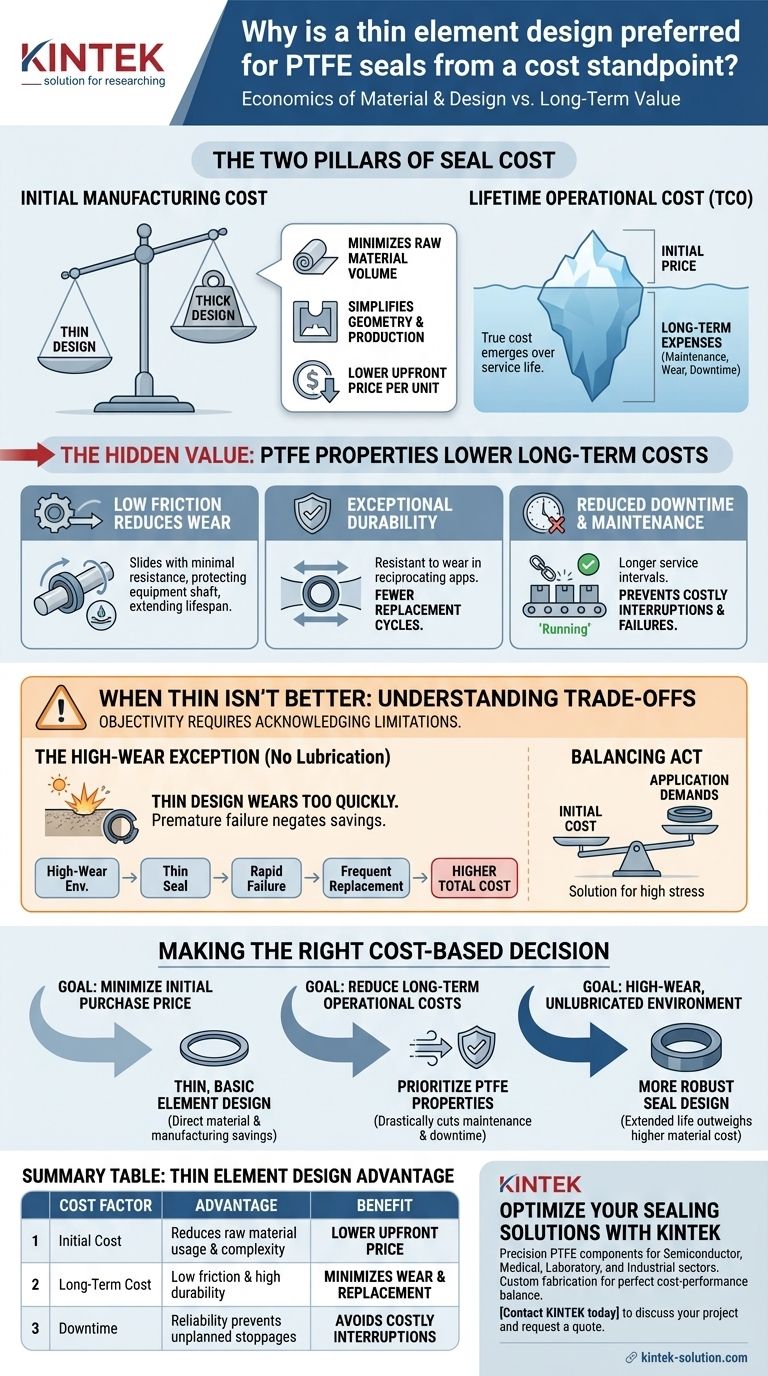

The Two Pillars of Seal Cost: Initial vs. Lifetime

When evaluating the cost of any component, it's crucial to look beyond the initial price tag. The total cost includes both the upfront manufacturing expense and the long-term operational expenses associated with its use.

Minimizing Upfront Manufacturing Cost

The most direct factors in a seal's initial price are material volume and manufacturing complexity.

A thin element design is the most straightforward way to reduce material consumption. Less raw PTFE used per seal translates directly into a lower cost per unit.

Similarly, keeping the element design as basic as possible simplifies the manufacturing process, further reducing the initial cost.

The Hidden Value: Reducing Total Cost of Ownership

The initial price is often a small fraction of a seal's total economic impact. The true value of a well-designed PTFE seal emerges during its service life.

High-performance materials like PTFE are chosen because they prevent much larger costs down the line, such as equipment failure, production stoppages, and frequent maintenance.

How PTFE Properties Lower Long-Term Costs

The unique characteristics of PTFE are what make it a cost-effective choice for demanding applications, often saving far more money than is spent on the component itself.

Low Friction Reduces Wear and Tear

PTFE has an extremely low coefficient of friction. This means it slides against other surfaces—like a rotating shaft—with minimal resistance.

This property drastically reduces wear on both the seal and the equipment it protects, extending the lifespan of more expensive components and preventing premature failure.

Exceptional Durability and Wear Resistance

PTFE seals are highly durable and resistant to wear, especially in reciprocating (back-and-forth) applications.

This durability means fewer replacement cycles are needed over the life of the equipment. This cuts down on the cost of new seals, the labor required for replacement, and the associated administrative overhead.

Reduced Downtime and Maintenance

The combination of low friction and high durability leads to significantly longer service intervals.

For any industrial operation, unplanned downtime is a massive cost driver. A reliable seal that prevents leaks and equipment failure minimizes these costly interruptions, making it an extremely valuable component.

Understanding the Trade-offs: When Thin Isn't Better

While a thin design is often the starting point for cost efficiency, it is not a universal solution. Objectivity requires acknowledging its limitations.

The High-Wear Exception

In certain applications, particularly those without lubrication where high wear rates are expected, a thin seal is the wrong choice.

The minimal material in a thin design would wear away too quickly, leading to premature failure. This would negate any initial cost savings and result in more frequent, costly replacements.

Balancing Initial Cost with Application Demands

The optimal design is not necessarily the cheapest one to produce, but the one that is most cost-effective for its specific operating environment.

For a high-stress application, a thicker, more robust seal—despite its higher material cost—is the more economical choice because its extended service life will provide a better return on investment.

Making the Right Cost-Based Decision

To select the most economical seal, you must align the design with your primary financial goal.

- If your primary focus is minimizing initial purchase price: A thin, basic element design is the most direct way to reduce material and manufacturing costs.

- If your primary focus is reducing long-term operational costs: The inherent properties of PTFE, such as low friction and durability, are more critical than element thickness, as they drastically cut maintenance and downtime expenses.

- If you are designing for a high-wear, unlubricated environment: Prioritize a more robust seal design over a thin one, as the longer service life will easily outweigh the higher upfront material cost.

Ultimately, the most cost-effective PTFE seal is one that balances minimal material usage with the specific performance demands of your application.

Summary Table:

| Cost Factor | Thin Element Design Advantage |

|---|---|

| Initial Cost | Reduces raw material usage and manufacturing complexity. |

| Long-Term Cost | Low friction minimizes equipment wear; high durability reduces replacement frequency. |

| Downtime | Reliability prevents costly unplanned maintenance and production stoppages. |

Optimize your sealing solutions with KINTEK's precision PTFE components.

Our expertise in custom fabrication ensures you get the perfect balance of cost-effective design and long-term performance for your specific application in the semiconductor, medical, laboratory, or industrial sectors. From prototypes to high-volume orders, we deliver the reliability that minimizes your total cost of ownership.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance