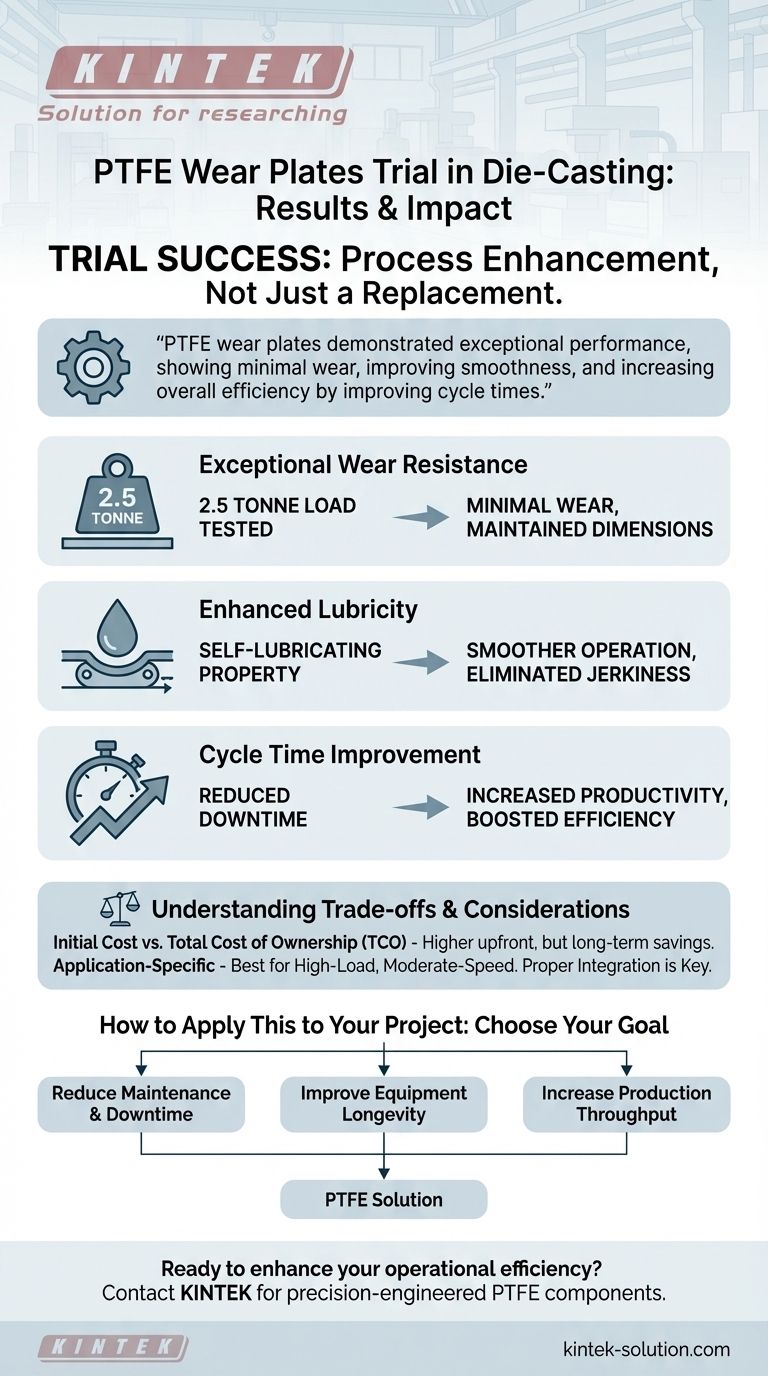

In short, the trial was a success. The PTFE wear plates demonstrated exceptional performance in the die-casting environment, showing minimal wear under significant load, improving operational smoothness, and increasing overall efficiency by improving cycle times.

The core takeaway is that PTFE wear plates are not just a durable replacement; they are a process enhancement. Their self-lubricating nature directly translates to reduced downtime and increased productivity in high-stress industrial applications.

A Breakdown of the Performance Metrics

The trial results can be understood by examining three key areas of improvement. Each points to a significant operational advantage over traditional materials that require constant lubrication and maintenance.

Exceptional Wear Resistance

The plates were subjected to a 2.5-tonne load, a substantial force typical in die-casting operations.

Despite this heavy and continuous stress, the PTFE wear plates showed minimal wear. Critically, they maintained their original dimensions, ensuring consistent precision and alignment in the machinery.

Enhanced Lubricity and Smoother Operation

One of the most immediate benefits observed was a dramatic increase in lubricity. This inherent slipperiness is a core property of PTFE.

This resulted in much smoother equipment movement, completely eliminating the jerkiness that can occur with improperly lubricated metal-on-metal components. This smoothness reduces stress on motors, actuators, and the machine frame itself.

Cycle Time Improvement

The operational efficiency of the equipment saw a measurable boost, evidenced by an improved cycle time.

This improvement was a direct result of reduced downtime. Because the PTFE plates are self-lubricating, there was no need for the constant monitoring and re-application of grease, allowing the machinery to run for longer, uninterrupted periods.

Understanding the Trade-offs and Considerations

While the trial results are overwhelmingly positive, a responsible technical evaluation requires looking at the complete picture. Adopting any new material technology involves understanding its context and potential limitations.

Initial Cost vs. Total Cost of Ownership

Specialized polymer components like PTFE can have a higher initial purchase price than traditional bronze or steel wear plates.

However, this upfront cost must be weighed against the total cost of ownership. Savings from eliminated lubricants, reduced labor for maintenance, and increased production from less downtime often provide a rapid return on the initial investment.

Application-Specific Demands

The success in this die-casting trial highlights PTFE's suitability for high-load, moderate-speed applications.

It is crucial to evaluate if the specific temperature, abrasive contaminants, and impact forces of your unique environment fall within PTFE's operational limits. Not every high-wear application is a perfect fit.

System Integration

The performance of a wear plate doesn't exist in a vacuum. Its effectiveness is tied to the design and condition of the machinery it's installed in.

Proper surface preparation, correct fastening, and ensuring alignment are critical. A high-performance component installed improperly will yield poor results and could fail prematurely.

How to Apply This to Your Project

To determine if PTFE wear plates are the right solution, consider your primary operational goal.

- If your primary focus is reducing maintenance costs and downtime: The self-lubricating property of PTFE is the key benefit, as it virtually eliminates the labor and material costs associated with continuous lubrication.

- If your primary focus is improving equipment longevity: The combination of low friction and high wear resistance reduces mechanical stress, leading to longer service life for both the plates and the machinery itself.

- If your primary focus is increasing production throughput: The reduction in downtime for lubrication directly translates to more cycles per shift, boosting overall output and efficiency.

Ultimately, integrating advanced materials like PTFE offers a clear path toward more efficient, reliable, and cost-effective industrial operations.

Summary Table:

| Key Metric | Trial Result |

|---|---|

| Load Tested | 2.5 Tonnes |

| Wear Resistance | Minimal wear, maintained dimensions |

| Lubricity | Self-lubricating, eliminated jerkiness |

| Operational Impact | Reduced downtime, improved cycle time |

Ready to enhance your operational efficiency and reduce maintenance costs?

The successful die-casting trial demonstrates how KINTEK's precision-engineered PTFE components can solve high-wear challenges. We specialize in manufacturing custom PTFE seals, liners, labware, and wear plates for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume orders, our focus on precision production ensures a perfect fit and superior performance for your specific application.

Contact us today to discuss how our PTFE solutions can improve your productivity and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications