In industrial machinery, Teflon bushings are most commonly applied in high-friction, chemically aggressive, or contamination-sensitive environments where traditional lubrication is impractical or undesirable. You will find them ensuring smooth operation in components like pump housings, valve guides, conveyor systems, and textile equipment, where they reduce wear and eliminate the need for grease.

The decision to use a Teflon bushing is less about replacing a specific part and more about solving a specific environmental problem. Its unique combination of low friction, chemical inertness, and temperature stability makes it the superior choice for applications where metal bushings would quickly fail due to corrosion, seizure, or contamination.

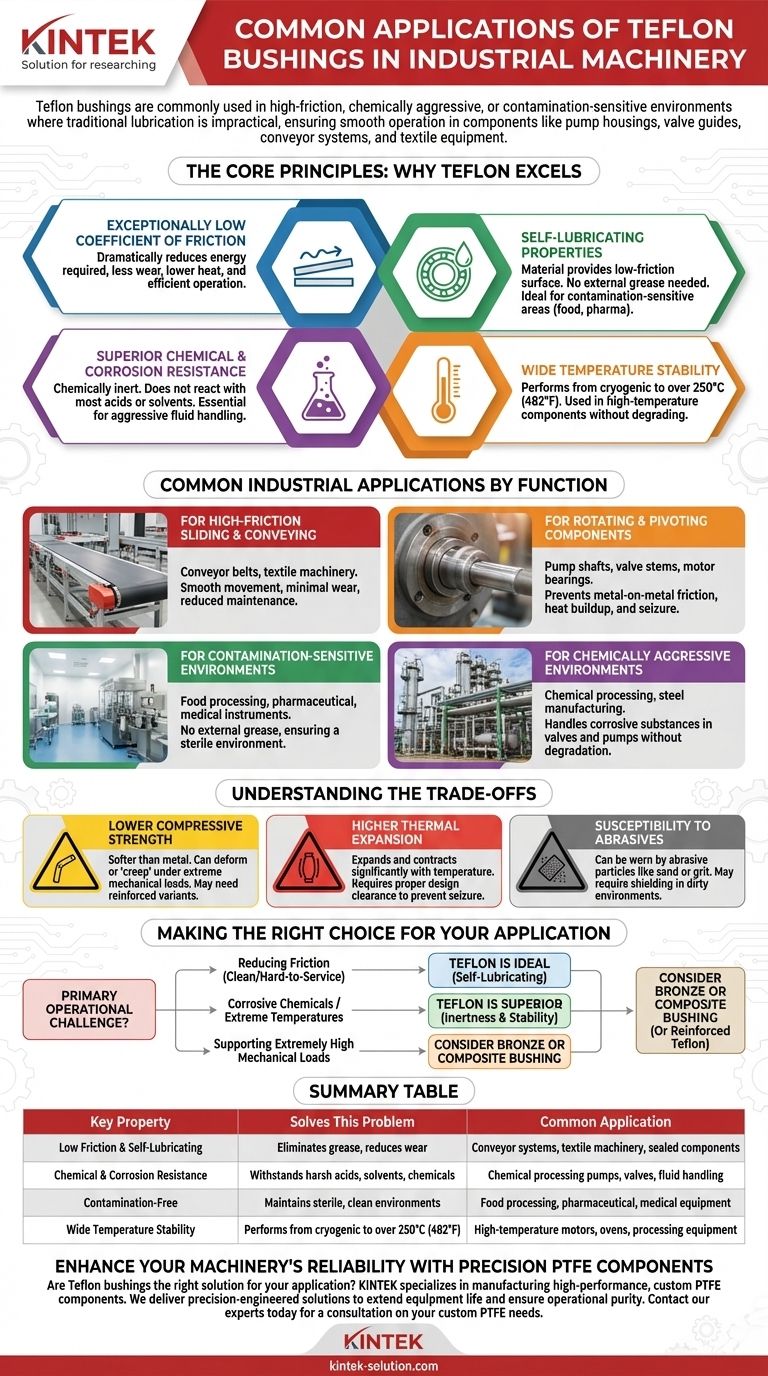

The Core Principles: Why Teflon Excels

Teflon (PTFE) isn't simply a durable plastic; its molecular structure gives it a set of properties that make it a unique problem-solver in mechanical systems. Understanding these properties explains its widespread use.

Exceptionally Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it inherently "slippery." This dramatically reduces the energy required to move parts against each other.

This property directly translates to less mechanical wear, lower heat generation, and more efficient operation of the machinery.

Self-Lubricating Properties

Unlike metal bushings that require a constant film of oil or grease, Teflon is self-lubricating. The material itself provides the low-friction surface.

This is critical in applications where external lubricants could contaminate the product (e.g., food or pharmaceutical manufacturing) or are difficult to reapply (e.g., sealed or inaccessible components).

Superior Chemical and Corrosion Resistance

Teflon is chemically inert, meaning it does not react with most industrial chemicals, acids, and solvents.

This makes it the only viable option for bushings inside pumps and valves that handle aggressive or corrosive fluids, where even stainless steel would degrade over time.

Wide Temperature Stability

Teflon maintains its structural integrity and performance across a vast temperature range, from cryogenic lows to highs exceeding 250°C (482°F).

This allows it to be used reliably in high-temperature motor components, gears, and processing equipment without melting, degrading, or becoming brittle.

Common Industrial Applications by Function

Instead of a simple list, it is more useful to group applications by the primary problem the Teflon bushing is solving.

For High-Friction Sliding and Conveying

In systems like conveyor belts and textile machinery, parts are in constant sliding contact. Teflon bushings and wear strips allow for smooth, uninterrupted movement with minimal wear, ensuring longevity and reducing maintenance downtime.

For Rotating and Pivoting Components

Components like pump shafts, valve stems, and motor bearings must rotate or pivot freely. Teflon bushings prevent the metal-on-metal contact that leads to friction, heat buildup, and eventual seizure, ensuring efficient and reliable rotation.

For Contamination-Sensitive Environments

In food processing, pharmaceutical manufacturing, and medical instruments, cleanliness is paramount. Because Teflon bushings require no external grease or oil, they eliminate a primary source of potential contamination, ensuring a sterile operational environment.

For Chemically Aggressive Environments

Within chemical processing plants and steel manufacturing, equipment is exposed to highly corrosive substances. Teflon's chemical inertness makes it ideal for bushings in special valves and pumps that handle these harsh materials without degrading.

Understanding the Trade-offs

While powerful, Teflon is not a universal solution. An objective analysis requires understanding its limitations.

Lower Compressive Strength

Compared to bronze or steel, Teflon is a softer material. Under extremely high mechanical loads, a standard Teflon bushing can deform or "creep" over time.

For very high-pressure applications, a metal or composite bushing may be necessary, or a specialized, filled-Teflon variant designed for higher loads.

Higher Thermal Expansion

Teflon expands and contracts with temperature changes more significantly than metals. This must be accounted for in the design of the housing and shaft.

Without proper clearance, a bushing in a high-temperature application could expand and seize the shaft it is meant to support.

Susceptibility to Abrasives

While excellent for smooth, sliding friction, Teflon can be worn down by abrasive particles like sand, metal filings, or grit. In dirty, abrasive environments, the bushing may require shielding to prevent premature failure.

Making the Right Choice for Your Application

Selecting the right bushing material depends entirely on your primary operational challenge.

- If your primary focus is reducing friction in a clean or hard-to-service environment: Teflon is an ideal choice due to its self-lubricating properties.

- If your primary focus is handling corrosive chemicals or extreme temperatures: Teflon's chemical inertness and temperature stability make it superior to most metal alternatives.

- If your primary focus is supporting extremely high mechanical loads: You may need to consider a bronze or composite bushing, or a reinforced Teflon variant, as standard PTFE can deform.

By understanding these core properties and trade-offs, you can deploy Teflon bushings not just as a replacement part, but as a strategic upgrade to enhance machine reliability and efficiency.

Summary Table:

| Key Property | Solves This Problem | Common Application |

|---|---|---|

| Low Friction & Self-Lubricating | Eliminates need for grease, reduces wear | Conveyor systems, textile machinery, sealed components |

| Chemical & Corrosion Resistance | Withstands harsh acids, solvents, and chemicals | Chemical processing pumps, valves, and fluid handling systems |

| Contamination-Free | Maintains sterile, clean environments | Food processing, pharmaceutical, and medical equipment |

| Wide Temperature Stability | Performs from cryogenic to over 250°C (482°F) | High-temperature motors, ovens, and processing equipment |

Enhance Your Machinery's Reliability with Precision PTFE Components

Are Teflon bushings the right solution for your high-friction, corrosive, or contamination-sensitive application? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, bushings, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver more than just parts; we provide durable, precision-engineered solutions that extend equipment life, reduce maintenance, and ensure operational purity. From initial prototypes to high-volume production, our team ensures your specifications are met with exacting quality.

Let's solve your specific challenge together. Contact our experts today for a consultation on your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the advantages of using glass as a filler in PTFE? Enhance Strength and Wear Resistance

- What is a Teflon O-ring? A Guide to PTFE Seals for Extreme Chemical and Temperature Resistance

- What advantages do PTFE coatings offer in terms of durability and maintenance? Maximize Component Lifespan

- What is porous PTFE used for? Advanced Filtration for Harsh Chemical & High-Temp Environments

- Why are fillers added to PTFE compounds? Enhance Wear, Strength, and Performance

- Why are PTFE rotary seals becoming a preferred choice for engineers and OEMs? Solve Critical Performance Failures

- How do PTFE lip seals compare to traditional elastomer lip seals? A Guide to High-Performance Sealing

- What are the key properties that make PTFE an effective sealing material? Unlock Superior Performance in Harsh Environments