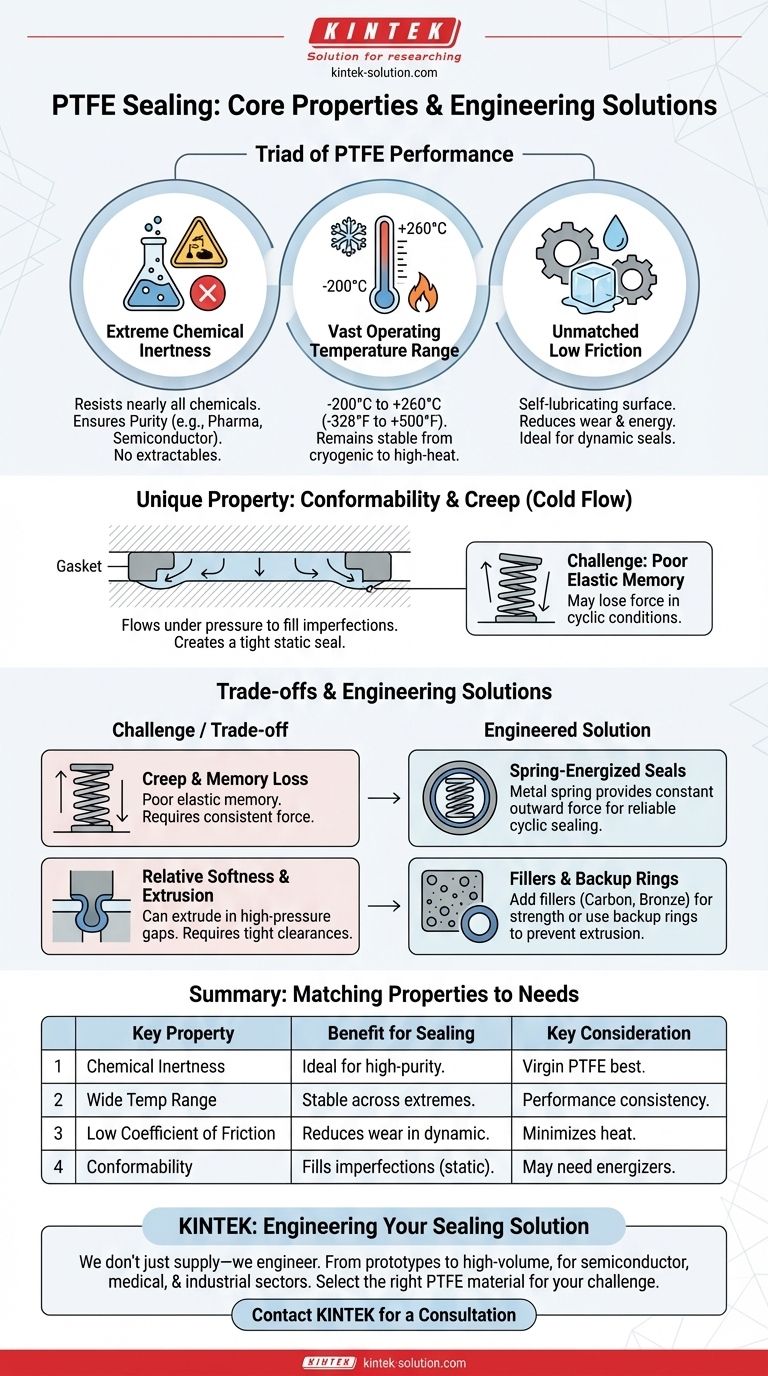

The effectiveness of Polytetrafluoroethylene (PTFE) as a sealing material stems from a unique combination of three core properties: its extreme chemical inertness, its vast operational temperature range, and its exceptionally low coefficient of friction. This triad allows PTFE to create a reliable and durable seal in aggressive industrial environments where most other materials would quickly fail.

While many materials excel in one specific area, PTFE's value comes from its holistic resilience. It doesn't just resist chemicals or heat; it resists them simultaneously while providing a low-friction, self-lubricating surface, making it a uniquely versatile solution for the most demanding sealing challenges.

The Pillars of PTFE Sealing Performance

To understand why PTFE is a default choice for critical applications, we must examine how its primary characteristics contribute directly to sealing integrity.

Extreme Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This property is not just about avoiding degradation; it's about ensuring the seal itself does not contaminate the process media.

This makes it indispensable in industries like pharmaceuticals, food and beverage, and semiconductor manufacturing, where purity is paramount. The material has virtually no extractables, meaning it won't leach particles into the system.

A Vast Operating Temperature Range

PTFE maintains its integrity and sealing properties across an exceptionally broad temperature spectrum, typically cited from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-temperature processing. Unlike many elastomers that become brittle when frozen or degrade with heat, PTFE remains stable and functional.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "self-lubricating" characteristic is critical for dynamic seals, such as those on rotating shafts or reciprocating rods.

This low-friction surface minimizes heat generation, reduces wear on both the seal and the hardware, and lowers the energy required to operate the equipment, leading to a longer and more efficient service life.

Material Conformability and Creep

A unique and vital property of PTFE is its tendency to "creep" or cold-flow under pressure. While this can be a drawback in some applications, it is a significant advantage for static seals like gaskets.

This lack of material "memory" allows the PTFE to flow into and fill microscopic imperfections on mating surfaces. This creates an exceptionally tight and leak-free seal that is difficult to achieve with more rigid materials.

Understanding the Trade-offs of PTFE

No material is perfect. Acknowledging the inherent limitations of PTFE is key to engineering a successful sealing solution and avoiding common pitfalls.

'Creep' vs. 'Elastic Memory'

The same creep that allows PTFE to conform so well means it has poor elastic memory. Once compressed, it does not readily spring back to its original shape.

In applications with frequent pressure or temperature cycling, this can lead to a loss of sealing force over time. The seal conforms during the high-pressure cycle but may not maintain contact when the pressure is removed, creating a potential leak path.

The Need for Fillers and Energizers

To counteract the low mechanical strength and creep of virgin PTFE, it is often blended with fillers. Materials like carbon, fiberglass, or bronze are added to enhance stiffness, improve wear resistance, and reduce creep.

For dynamic seals or applications requiring consistent sealing force, spring-energized PTFE seals are used. A metal spring inside the seal jacket provides the constant outward force that the PTFE material itself lacks, ensuring a reliable seal through varying conditions.

Relative Softness and Extrusion Risk

PTFE is a relatively soft material. In very high-pressure applications, the seal can be extruded or forced into the clearance gap between two hardware components if that gap is too large.

Proper hardware design, including tight clearances and the potential use of backup rings, is essential to prevent this mode of failure.

Making the Right Choice for Your Application

Selecting the correct form of PTFE is about matching the material's properties to the specific demands of your operating environment.

- If your primary focus is aggressive chemicals or high purity: Virgin PTFE is often the best choice due to its unparalleled chemical inertness and lack of additives.

- If your primary focus is dynamic sealing with high wear: A filled PTFE, such as carbon- or bronze-filled, will provide the necessary mechanical strength and durability.

- If your primary focus is maintaining a seal through pressure or temperature cycles: A spring-energized PTFE seal is engineered to compensate for the material's low elastic memory.

Ultimately, understanding these core properties and their trade-offs empowers you to specify a PTFE seal engineered for maximum reliability in your specific environment.

Summary Table:

| Key Property | Benefit for Sealing | Key Consideration |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals; ideal for high-purity applications. | Virgin PTFE offers the best chemical resistance. |

| Wide Temp Range (-200°C to +260°C) | Maintains integrity from cryogenic to high-heat processes. | Stable performance where other materials fail. |

| Low Coefficient of Friction | Self-lubricating; reduces wear and operating energy in dynamic seals. | Minimizes heat generation and extends service life. |

| Conformability (Cold Flow) | Flows to fill surface imperfections for leak-tight static seals. | Poor elastic memory; may require energizers for cyclic conditions. |

Need a PTFE Seal Engineered for Your Specific Challenge?

At KINTEK, we don't just supply PTFE components—we engineer solutions. Whether your application demands extreme chemical purity, high-temperature stability, or low-friction dynamic sealing, our expertise ensures you get a seal designed for maximum reliability and longevity.

We specialize in custom fabrication, from prototypes to high-volume orders, for the semiconductor, medical, laboratory, and industrial sectors. Let us help you select the right material—be it virgin, filled, or spring-energized PTFE—to solve your most demanding sealing problems.

Contact KINTEK today for a consultation and see how our precision PTFE components can enhance your system's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers