In short, engineers prefer PTFE rotary seals because they solve critical performance failures where traditional elastomeric seals cannot. They reliably handle extreme conditions—including high speeds, aggressive chemicals, and wide temperature ranges—that are increasingly common in modern, high-efficiency machinery. This allows for designs with greater reliability, longer service life, and lower maintenance requirements.

The growing adoption of PTFE rotary seals is not about replacing every seal; it's a direct response to engineering applications being pushed to performance limits. PTFE offers a unique combination of chemical inertness, thermal stability, and low friction that standard rubber seals simply cannot match under intense operational demands.

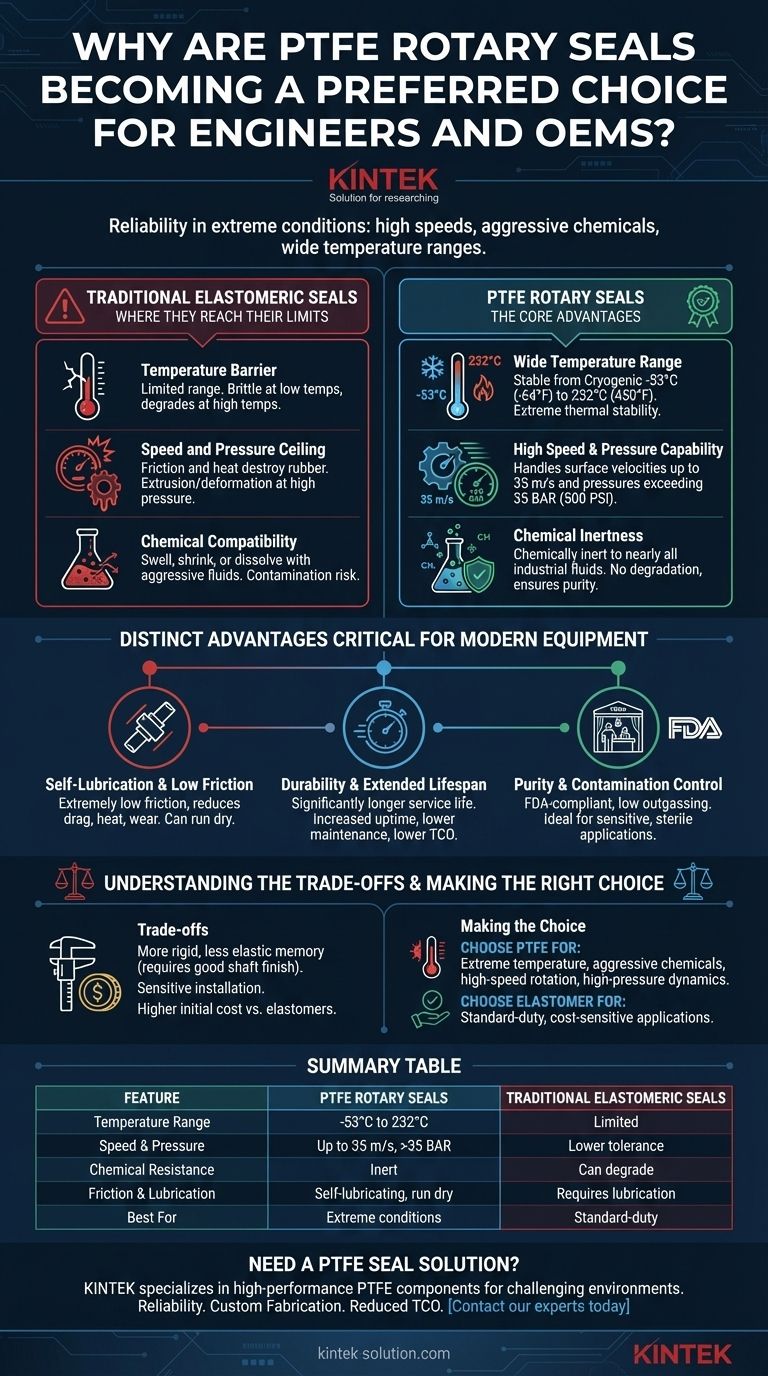

Where Traditional Elastomeric Seals Reach Their Limits

The fundamental reason for PTFE's rise is that it excels precisely where conventional materials, like rubber O-rings, begin to degrade and fail. Engineers turn to PTFE when their application pushes beyond the physical boundaries of elastomers.

The Temperature Barrier

Most elastomeric seals have a limited operating temperature range. They become brittle at low temperatures and break down or degrade rapidly at high temperatures.

PTFE seals, by contrast, function effectively in an exceptionally wide thermal window, from cryogenic lows of -53°C (-64°F) up to 232°C (450°F), ensuring stable performance where others would fail.

The Speed and Pressure Ceiling

High rotational speeds generate friction and heat, which can quickly destroy a standard rubber seal. Similarly, high pressures can cause elastomers to extrude or deform permanently.

PTFE's material properties allow it to handle surface velocities up to 35 m/s and pressures exceeding 35 BAR (500 PSI), making it essential for high-performance motors, compressors, and gearboxes.

The Chemical Compatibility Problem

Modern industrial processes often involve aggressive chemicals, solvents, or lubricants that can cause elastomeric seals to swell, shrink, or dissolve over time.

PTFE is chemically inert to nearly all industrial fluids. This universal compatibility eliminates the risk of chemical degradation, ensuring seal integrity and preventing system contamination.

The Core Advantages of PTFE in Demanding Applications

By overcoming the limitations of older materials, PTFE provides a set of distinct advantages that are critical for modern equipment design and reliability.

Self-Lubrication and Low Friction

A key characteristic of PTFE is its extremely low coefficient of friction. This self-lubricating property is vital because it drastically reduces drag, heat generation, and wear on the rotating shaft.

This allows PTFE seals to run dry without immediate damage, a condition that would cause catastrophic failure in most elastomeric seals.

Durability and Extended Lifespan

The combination of low friction, chemical resistance, and thermal stability results in a seal that lasts significantly longer.

For OEMs and end-users, this translates directly to increased uptime, greater machine reliability, and a lower total cost of ownership due to reduced maintenance cycles and fewer breakdowns.

Purity and Contamination Control

In sensitive industries like pharmaceuticals, food and beverage, and aerospace, material purity is non-negotiable. PTFE materials can be FDA-compliant and exhibit low outgassing properties.

This ensures they do not leach contaminants into the process media or compromise vacuum environments, making them ideal for sterile or cleanroom applications.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. An objective analysis requires understanding their limitations compared to traditional elastomers.

Elasticity and Memory

PTFE is a more rigid material than rubber and has less "elastic memory." This means it is less forgiving of shaft imperfections or significant variations in hardware tolerances.

An elastomeric seal can often conform to minor surface flaws, whereas a PTFE seal requires a well-finished and consistent shaft surface for optimal performance.

Installation Complexity

The rigidity of PTFE can make installation more sensitive. Unlike a flexible O-ring that can be easily stretched into a groove, a PTFE seal often requires specific tools or careful procedures to prevent damage to the sealing lip during assembly.

Cost Considerations

PTFE seals typically have a higher upfront material and manufacturing cost compared to standard nitrile or viton seals.

This initial investment must be weighed against the long-term benefits of extended lifespan, reduced downtime, and superior performance in demanding conditions.

Making the Right Choice for Your Goal

Selecting the appropriate seal material is a crucial design decision based on balancing performance requirements with cost.

- If your primary focus is extreme temperature or aggressive chemical exposure: PTFE is the default and often the only viable choice.

- If your primary focus is high-speed rotation or high-pressure dynamics: PTFE's low-friction and durable properties are necessary to prevent premature failure.

- If your primary focus is a standard-duty, cost-sensitive application: A traditional elastomeric seal likely remains the most economical and effective solution.

Ultimately, choosing a PTFE rotary seal is an engineering decision to prioritize long-term reliability and performance in applications where standard materials are simply not sufficient.

Summary Table:

| Feature | PTFE Rotary Seals | Traditional Elastomeric Seals |

|---|---|---|

| Temperature Range | -53°C to 232°C (-64°F to 450°F) | Limited range, degrades at extremes |

| Speed & Pressure | Up to 35 m/s, >35 BAR (500 PSI) | Lower tolerance for friction and heat |

| Chemical Resistance | Inert to nearly all industrial fluids | Can swell, shrink, or dissolve |

| Friction & Lubrication | Self-lubricating, can run dry | Requires lubrication, higher friction |

| Best For | Extreme conditions, long-term reliability | Standard-duty, cost-sensitive applications |

Need a PTFE Seal Solution for Your Demanding Application?

Your designs push the limits of performance, and your sealing components shouldn't be the weak link. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom rotary seals, for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors.

We partner with engineers and OEMs to deliver:

- Reliability in Extreme Conditions: Seals that withstand high speeds, aggressive chemicals, and wide temperature ranges.

- Custom Fabrication: From initial prototypes to high-volume production runs, tailored to your exact specifications.

- Reduced Total Cost of Ownership: Durable components that increase uptime and minimize maintenance.

Let's engineer a solution that meets your performance goals. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What temperature range can PTFE seals typically operate in? From Cryogenic -200°C to High-Temp 260°C

- What are the key features of PTFE reducing flanges? Superior Chemical Resistance and Leak-Proof Performance

- What is a PTFE lined dual plate check valve? A Guide to Corrosion-Resistant Backflow Prevention

- What are PTFE-lined plug valves and their primary purpose? Achieve Superior Control for Corrosive & High-Purity Fluids

- Why should traditional lubricants not be used with PTFE-lined bearings? Avoid Premature Failure and High Friction

- What are the advantages of using ePTFE sheets for gaskets? Superior Sealing for Demanding Conditions

- What are PTFE slide bearings and what is their primary function in construction? Manage Structural Movement Safely

- What are the advantages of multi-axis CNC machines for PTFE machining? Achieve Superior Precision for Complex Parts