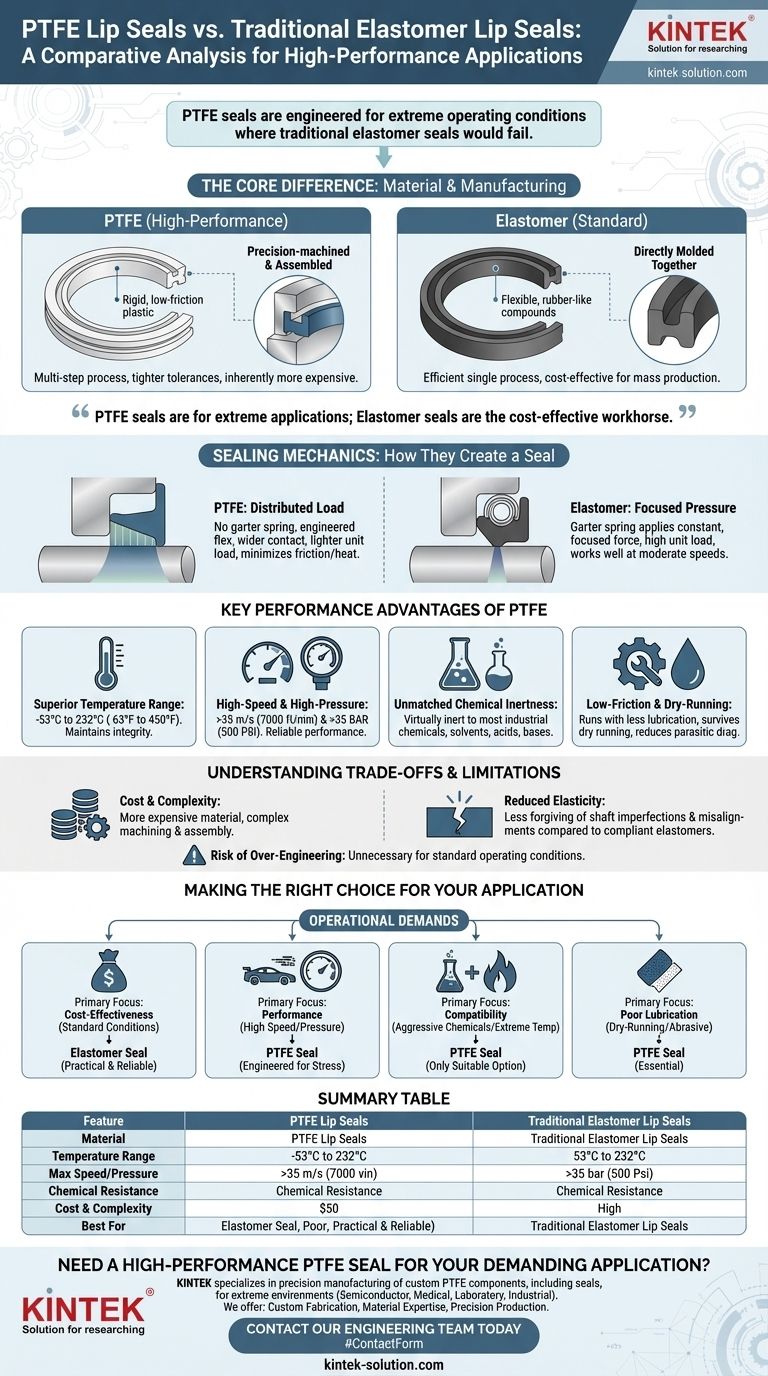

At a fundamental level, PTFE lip seals are a high-performance solution engineered for extreme operating conditions where traditional elastomer seals would fail. While both serve to seal rotating shafts, PTFE seals are distinguished by their material properties and construction, allowing them to handle significantly higher speeds, pressures, temperatures, and more aggressive chemicals than their elastomeric counterparts.

The choice between PTFE and elastomer lip seals is not about which is "better," but which is engineered for the specific demands of your environment. PTFE seals are a specialized solution for extreme applications, while elastomer seals remain the cost-effective workhorse for standard operating parameters.

The Core Difference: Material and Manufacturing

The fundamental distinctions in performance originate from the materials used and how the seals are constructed.

How Elastomer Seals Are Made

Traditional seals use elastomeric materials (like Nitrile, Viton, or Silicone) which are flexible and rubber-like.

This allows the sealing lip and the outer casing to be directly molded together in a single, efficient process, making them highly cost-effective for mass production.

How PTFE Seals Are Constructed

PTFE (Polytetrafluoroethylene) is a rigid, low-friction plastic that cannot be molded in the same way as rubber.

Instead, the PTFE sealing lip must be precision-machined separately and then mechanically assembled or press-fitted into a metal casing. This multi-step process requires tighter tolerances and is inherently more expensive.

Sealing Mechanics: How They Create a Seal

The material differences dictate a completely different approach to how the seal contacts the shaft.

The Elastomer Approach: Focused Pressure

Elastomer seals typically use a garter spring to apply a constant, focused force on a narrow contact point on the shaft.

This high "unit load" works well at moderate speeds but can generate excessive friction and heat at higher velocities, leading to premature wear and failure.

The PTFE Approach: Distributed Load

PTFE seals do not use a garter spring. Instead, they rely on the engineered flex of the lip and casing to provide sealing force.

They feature a wider lip contact pattern with a much lighter unit loading. This spreads the force over a larger area, minimizing friction and heat generation, which is critical for surviving high-speed and high-pressure applications.

Key Performance Advantages of PTFE

The unique construction and material properties of PTFE give it a clear advantage in demanding environments.

Superior Temperature Range

PTFE maintains its integrity across an exceptionally wide temperature range, typically from -53°C to 232°C (-63°F to 450°F). Elastomers have much narrower operating windows and will become brittle or degrade outside of them.

High-Speed and High-Pressure Capability

PTFE's low-friction nature allows it to operate reliably at shaft surface speeds exceeding 35 m/s (7000 ft/min) and system pressures above 35 BAR (500 PSI), far beyond the limits of most elastomer seals.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, acids, and bases. This makes it the only viable choice when sealing aggressive or corrosive media that would quickly destroy an elastomer.

Low-Friction and Dry-Running Operation

The extremely low coefficient of friction allows PTFE seals to run with less lubrication and even survive short periods of dry running. This also reduces parasitic drag and energy consumption in the system.

Understanding the Trade-offs and Limitations

Choosing an advanced material like PTFE involves clear trade-offs that must be considered.

Cost and Complexity

The primary drawback of PTFE seals is cost. The raw material is more expensive, and the machining and assembly process is far more complex and costly than molding an elastomer seal.

Reduced Elasticity

PTFE is a rigid plastic, not a flexible rubber. It is less forgiving of shaft imperfections, surface finish irregularities, or minor installation misalignments compared to a compliant elastomer seal.

The Risk of Over-Engineering

Using a PTFE seal in an application with moderate temperature, speed, and pressure is often unnecessary. A standard elastomer seal can provide reliable performance in such conditions for a fraction of the cost.

Making the Right Choice for Your Application

Selecting the correct seal requires a clear understanding of your system's operational demands.

- If your primary focus is cost-effectiveness in standard conditions: An elastomer seal is the most practical and reliable choice.

- If your primary focus is performance under high shaft speeds or system pressures: A PTFE seal is specifically engineered to handle these stresses.

- If your primary focus is compatibility with aggressive chemicals or extreme temperatures: PTFE's material properties make it the only suitable option.

- If your application involves poor lubrication, dry-running, or abrasive media: The low-friction, durable nature of a PTFE seal is essential.

Ultimately, choosing the right seal is about precisely matching the material's capabilities to the operational demands of your system.

Summary Table:

| Feature | PTFE Lip Seals | Traditional Elastomer Lip Seals |

|---|---|---|

| Material | Rigid, low-friction plastic | Flexible, rubber-like compounds |

| Temperature Range | -53°C to 232°C (-63°F to 450°F) | Narrower, material-dependent |

| Max Speed/Pressure | >35 m/s & >35 BAR | Limited by friction and heat |

| Chemical Resistance | Excellent (Virtually inert) | Varies, often poor |

| Cost & Complexity | Higher (precision-machined) | Lower (cost-effective molding) |

| Best For | Extreme conditions, harsh chemicals | Standard, cost-sensitive applications |

Need a High-Performance PTFE Seal for Your Demanding Application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether your industry is semiconductor, medical, laboratory, or industrial, we understand the critical need for reliability in extreme environments.

We offer:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Material Expertise: Ensuring your seals handle extreme temperatures, aggressive chemicals, and high speeds.

- Precision Production: Tight tolerances and quality you can depend on.

Don't let a standard seal limit your system's performance. Contact our engineering team today to discuss your specific requirements and get a solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers