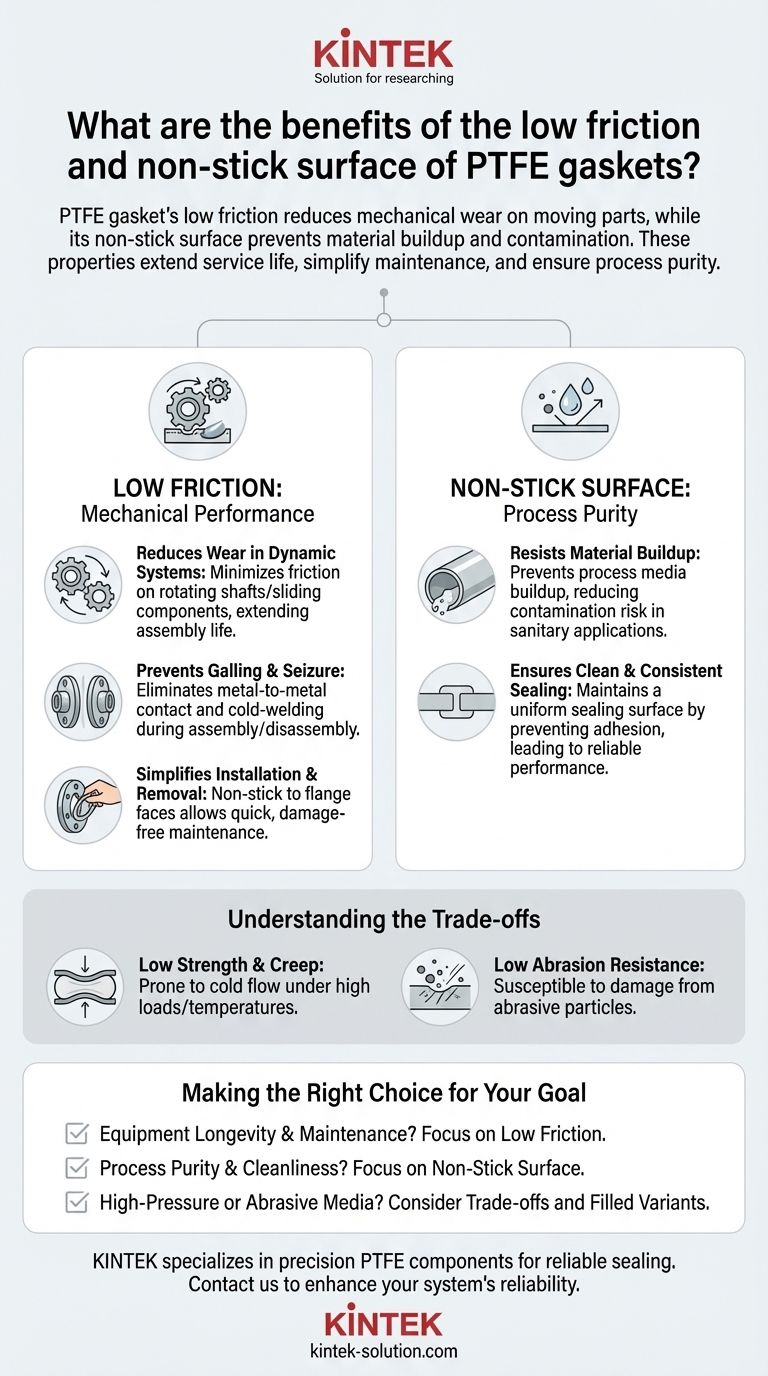

At its core, a PTFE gasket’s low friction reduces mechanical wear on moving parts, while its non-stick surface prevents material buildup and contamination. These two properties work together to extend the service life of your equipment, simplify maintenance, and ensure the purity of the process being sealed.

While often grouped together, the benefits of low friction and non-stick are distinct. Low friction primarily solves mechanical problems like wear and seizure, whereas the non-stick surface solves process problems like contamination and cleaning inefficiency.

The Impact of Low Friction on Mechanical Performance

The exceptionally low coefficient of friction in PTFE is a result of its unique molecular structure, where symmetrical polymer chains create a neutral electronic state. This translates directly into tangible mechanical advantages for sealed joints.

Reducing Wear in Dynamic Systems

In applications with rotating shafts or sliding components, friction is the primary driver of wear. The slick surface of a PTFE gasket minimizes this friction, drastically reducing the wear and tear on both the gasket and the more expensive metal parts it seals against.

This leads directly to a longer service life for the entire assembly, reducing the frequency of component replacement.

Preventing Galling and Seizure

Galling is a form of wear caused by adhesion between sliding metal surfaces, effectively "cold-welding" them together. It is a common and destructive problem when assembling or disassembling flange joints.

PTFE's low friction creates a barrier that prevents this metal-to-metal contact, ensuring that bolts can be tightened and flanges can be separated cleanly without damage to the sealing surfaces.

Simplifying Installation and Removal

The same property that prevents galling also makes maintenance far easier. A PTFE gasket will not stick to the flange faces, even after long periods of compression and thermal cycling.

This allows for quick and effortless removal without the need for scraping, which can damage the precision-machined sealing surfaces and introduce leak paths.

The Advantage of a Non-Stick Surface in Process Purity

PTFE's non-stick quality, famously used in cookware, is equally critical in industrial and sanitary applications. This property stems from its low surface energy, which prevents other materials from adhering to it.

Resisting Material Buildup

In industries like food processing, pharmaceuticals, and chemical manufacturing, the buildup of process media on a gasket can harbor bacteria or create contamination.

The non-stick surface of PTFE minimizes this buildup, ensuring a cleaner, more hygienic process and smooth, uninterrupted operation.

Ensuring Clean and Consistent Sealing

Any material that sticks to a gasket face can become a hardened deposit. Over time, these deposits can compromise the seal by creating an uneven surface, leading to potential leaks.

By preventing adhesion, a PTFE gasket maintains a clean, uniform sealing surface for more reliable, long-term performance.

Understanding the Trade-offs

No material is perfect. While PTFE’s key properties are highly beneficial, it's critical to understand their associated limitations to use them effectively.

Low Strength and Creep

The same molecular structure that gives PTFE its low friction also results in relatively low tensile strength. Under high, sustained bolt loads (especially at elevated temperatures), PTFE can be prone to "creep" or "cold flow," where the material slowly deforms and flows out of the joint.

This can lead to a loss of bolt torque and a potential leak. For high-pressure applications, filled PTFE variants (e.g., glass-filled or carbon-filled) are often used to improve creep resistance.

Low Abrasion Resistance

It is essential to distinguish between low friction and high abrasion resistance. While PTFE is very slippery, it is a soft material that can be easily damaged by abrasive particles or slurries.

In a system containing hard particulates, a more abrasion-resistant material might be a better choice, even if it has a higher coefficient of friction.

Making the Right Choice for Your Goal

Selecting a gasket requires matching the material's strengths to your primary objective.

- If your primary focus is equipment longevity and easier maintenance: The low-friction property is your key benefit, as it directly reduces wear on dynamic parts and prevents damage from galling during assembly.

- If your primary focus is process purity and cleanliness: The non-stick surface is non-negotiable, as it prevents material buildup, resists contamination, and simplifies cleaning cycles.

- If you are sealing a high-pressure joint or abrasive media: You must consider the trade-offs. A standard PTFE gasket may not be suitable, and a filled-PTFE or an alternative material may be required to prevent creep and abrasive wear.

Understanding these distinct properties allows you to deploy PTFE gaskets not just as a component, but as a strategic solution to enhance system reliability and efficiency.

Summary Table:

| Property | Primary Benefit | Key Application Focus |

|---|---|---|

| Low Friction | Reduces mechanical wear, prevents galling, simplifies maintenance | Equipment longevity, dynamic systems |

| Non-Stick Surface | Prevents material buildup, resists contamination, ensures cleanliness | Process purity, sanitary applications |

Need a high-performance sealing solution?

KINTEK specializes in manufacturing precision PTFE components, including gaskets, seals, and custom fabrications. Our expertise in PTFE's unique properties ensures your equipment benefits from extended service life, simplified maintenance, and guaranteed process purity.

Whether you require a standard solution or a custom PTFE component for the semiconductor, medical, laboratory, or industrial sectors, we provide reliable performance from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key differences between PTFE and non-PTFE RF PCB laminates? Choose the Right Material for Your High-Frequency Design

- What is the purpose of comparing spring energized PTFE seals to elastomeric seals? A Guide to Choosing the Right Seal

- What modern alternative to solid PTFE bushes was mentioned, and what are its advantages? Discover Glacier Bush for High-Load Applications

- What is required for the proper use of PTFE piston seals? Master the Two-Part System for Superior Performance

- Does modified PTFE (mPTFE) always outperform regular PTFE in seal performance? Make the Right Material Choice

- What are the key properties of PTFE Teflon O-rings? Unmatched Chemical & Thermal Resistance

- What are PTFE mill-type envelope gaskets used for? Seal Critical Flanges in Corrosive & High-Purity Systems

- Why are PTFE fasteners considered a key component in advanced medical devices? Unlock Superior Safety & Reliability