Choosing the right laminate is the foundation of high-frequency circuit design. The primary difference is that PTFE-based laminates offer superior electrical performance with extremely low signal loss, making them essential for demanding high-frequency applications. Non-PTFE laminates, while having higher signal loss, are significantly easier and less expensive to manufacture, making them a practical choice for less critical or cost-sensitive designs.

The decision between PTFE and non-PTFE laminates is a direct trade-off between electrical performance and manufacturability. PTFE provides the cleanest signal path for high-frequency circuits, while non-PTFE materials offer a more pragmatic, cost-effective solution where some performance compromise is acceptable.

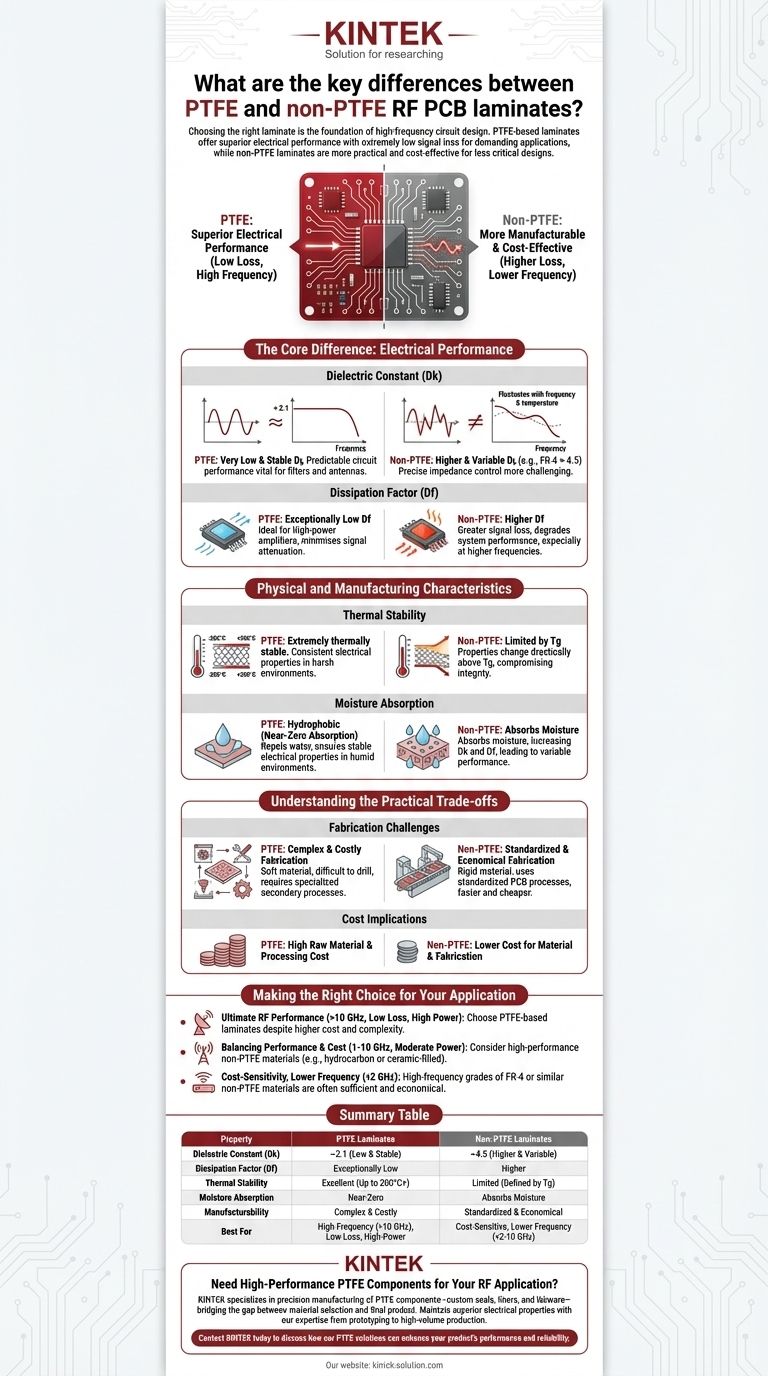

The Core Difference: Electrical Performance

The primary reason to select a specific RF laminate is its ability to maintain signal integrity at the target frequency. This is governed by two key electrical properties.

Dielectric Constant (Dk)

The dielectric constant determines the speed at which a signal travels through the material and is a critical factor in controlling circuit impedance.

PTFE is known for its very low and stable Dk, typically around 2.1. This stability across a wide frequency range ensures predictable circuit performance, which is vital for components like filters and antennas.

Non-PTFE materials, like the common FR-4, have a much higher Dk (around 4.5). More importantly, their Dk can fluctuate significantly with changes in frequency and temperature, making precise impedance control more challenging.

Dissipation Factor (Df)

The dissipation factor, or loss tangent, measures how much signal energy is absorbed and lost as heat within the laminate. Lower is always better.

PTFE has an exceptionally low Df. This means very little signal power is lost as it travels through the circuit, making it ideal for high-power amplifiers or systems where minimizing signal attenuation is critical.

Non-PTFE materials inherently have a higher Df. This results in greater signal loss, which becomes progressively worse as the frequency increases. This attenuation can degrade system performance, reducing signal-to-noise ratio and overall efficiency.

Physical and Manufacturing Characteristics

Beyond pure electrical properties, the physical nature of the material has major implications for manufacturing and real-world reliability.

Thermal Stability

This refers to how well the material maintains its electrical and mechanical properties over a wide range of temperatures.

PTFE is extremely thermally stable. Its electrical characteristics remain consistent from cryogenic temperatures to over 200°C, ensuring reliable performance in harsh environments.

Non-PTFE materials like FR-4 have a defined glass transition temperature (Tg). Above this temperature, the material's properties change drastically, which can compromise the circuit's integrity and reliability.

Moisture Absorption

Moisture is detrimental to RF performance because water has a high Dk.

PTFE is hydrophobic, meaning it repels water and has near-zero moisture absorption. This ensures its electrical properties remain stable even in humid environments.

Non-PTFE laminates can absorb moisture from the air, which can increase the material's Dk and Df. This leads to performance degradation that can vary with ambient humidity.

Understanding the Practical Trade-offs

The superior performance of PTFE comes at a cost, not just in price but also in manufacturing complexity.

The Challenge of Fabrication

PTFE is a soft, dimensionally unstable material. This softness makes it difficult to drill clean holes, often leading to smearing that requires specialized and costly secondary processes to correct.

Non-PTFE materials, especially FR-4, are rigid and use standardized manufacturing processes. This makes them far easier, faster, and cheaper to fabricate at nearly any PCB shop.

Cost Implications

The raw material cost for PTFE laminates is significantly higher than for their non-PTFE counterparts.

When combined with the specialized tooling and slower processing speeds required, the final cost of a PTFE-based PCB can be many times that of a comparable board made from a non-PTFE material.

Making the Right Choice for Your Application

Your application's specific requirements for frequency, power, and budget will dictate the optimal material choice.

- If your primary focus is ultimate RF performance (>10 GHz, low loss, or high power): PTFE-based laminates are the necessary choice despite their higher cost and fabrication complexity.

- If your primary focus is balancing performance and cost (1-10 GHz, moderate power): Consider high-performance non-PTFE materials, such as hydrocarbon or ceramic-filled laminates, which offer a good compromise.

- If your primary focus is cost-sensitivity for lower RF frequencies (<2 GHz): High-frequency grades of FR-4 or similar non-PTFE materials are often a sufficient and highly economical solution.

Understanding these core trade-offs empowers you to select a laminate that meets both your performance targets and your project constraints.

Summary Table:

| Property | PTFE Laminates | Non-PTFE Laminates |

|---|---|---|

| Dielectric Constant (Dk) | ~2.1 (Low & Stable) | ~4.5 (Higher & Variable) |

| Dissipation Factor (Df) | Exceptionally Low | Higher |

| Thermal Stability | Excellent (Up to 200°C+) | Limited (Defined by Tg) |

| Moisture Absorption | Near-Zero | Absorbs Moisture |

| Manufacturability | Complex & Costly | Standardized & Economical |

| Best For | High-Frequency (>10 GHz), Low-Loss, High-Power | Cost-Sensitive, Lower Frequency (<2-10 GHz) |

Need High-Performance PTFE Components for Your RF Application?

Choosing the right laminate is only the first step. You need a partner who understands the critical role of material integrity in high-frequency performance. KINTEK specializes in the precision manufacturing of PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, and industrial sectors.

We help you bridge the gap between material selection and final product by delivering components that maintain the superior electrical properties of PTFE, ensuring your designs perform as intended. From rapid prototyping to high-volume production, our expertise in custom PTFE fabrication supports your most demanding projects.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech