The modern alternative mentioned is a Glacier bush. This is a composite component consisting of a thin steel backing, a sintered bronze substrate, and a very thin surface layer of PTFE. Its primary advantage over a solid PTFE bush is vastly superior mechanical strength and durability, allowing it to be used in high-load applications.

The core decision between a solid PTFE bush and a Glacier-type bush is a trade-off. You must choose between the superior strength and durability of a standardized Glacier bush and the custom machinability of a solid PTFE bush for non-standard applications.

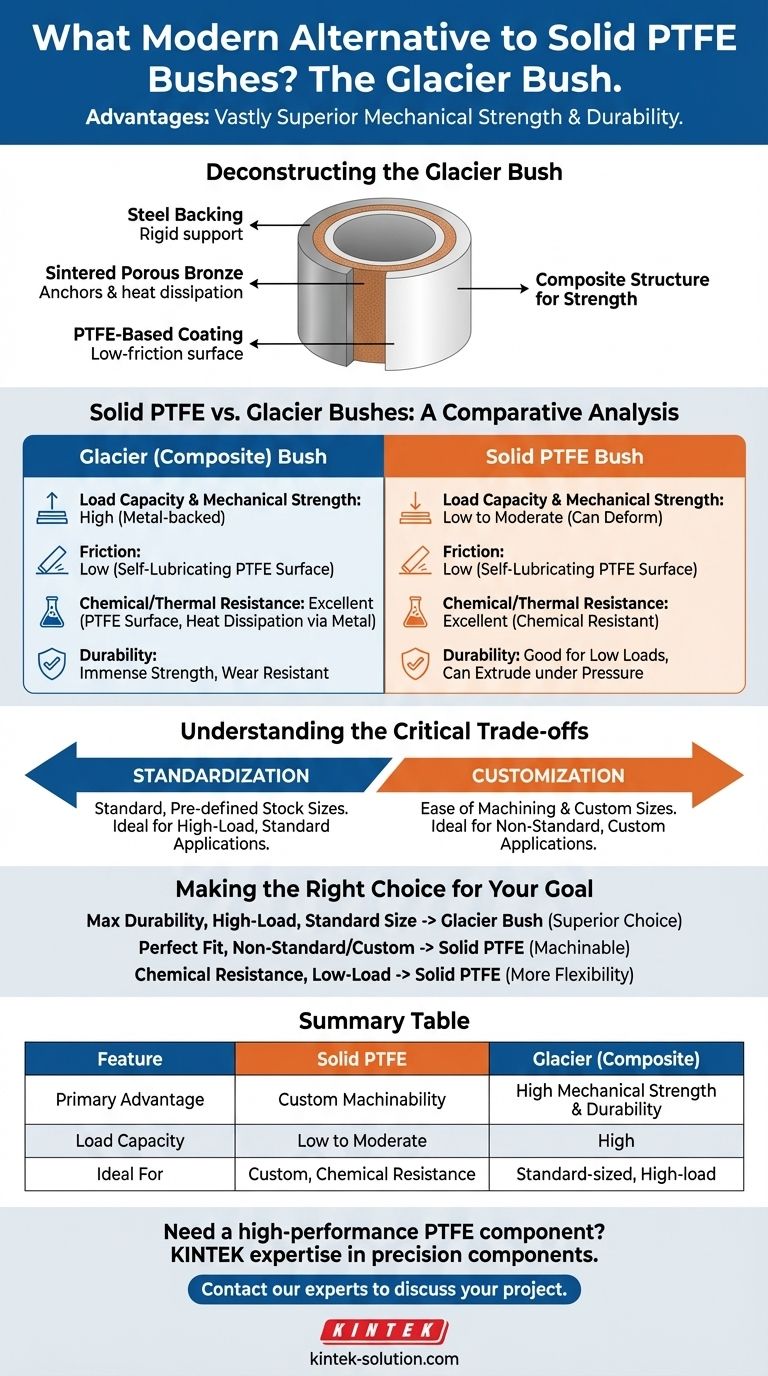

Deconstructing the Glacier Bush

A Glacier bush isn't a solid piece of plastic; it's a layered, engineered component designed to combine the best properties of metal and PTFE.

A Composite for Strength

The construction is key to its performance. It starts with a strong steel backing that provides rigid structural support.

Bonded to that is a layer of sintered porous bronze. This intermediate layer helps anchor the final surface and aids in heat dissipation.

The final, innermost layer is a thin PTFE-based coating that provides the extremely low-friction sliding surface.

The Advantage of Durability

This composite structure gives the Glacier bush immense strength and wear resistance compared to a solid polymer bush.

This durability makes it suitable for demanding, high-load applications where solid PTFE would fail, such as in crankshaft main bushes within an engine.

Solid PTFE vs. Glacier Bushes

While both utilize the low-friction properties of PTFE, their ideal use cases are fundamentally different due to their construction.

Load Capacity and Mechanical Strength

The steel and bronze layers give Glacier bushes a significantly higher load capacity.

Solid PTFE, while excellent for low friction, can deform or extrude under high pressure and is not suitable for high-load mechanical applications. Carbon-filled PTFE variants offer improved strength but still do not match a metal-backed bush.

Friction and Self-Lubrication

Both options provide an exceptionally low coefficient of friction because the contact surface is PTFE.

They are both considered self-lubricating, making them ideal for applications where regular maintenance is difficult or where lubricants could cause contamination.

Chemical and Thermal Resistance

The PTFE surface on both types provides excellent resistance to chemicals and a wide range of operating temperatures.

The metal backing of a Glacier bush can also help conduct heat away from the bearing surface more effectively than a solid polymer bush.

Understanding the Critical Trade-offs

Choosing the wrong type of bush for your application can lead to premature failure. The decision hinges almost entirely on one key factor: standardization versus customization.

The Customization Constraint

The primary limitation of Glacier bushes is that they are typically manufactured in standard, pre-defined stock sizes.

If your application involves a non-standard shaft or housing diameter, such as custom fork stanchions, you will likely be unable to find a Glacier bush that fits.

The Machinability Factor

Conversely, the key advantage of solid PTFE is its ease of machining and customization.

You can machine a solid PTFE billet into any custom size or shape required for a specific, non-standard application. This flexibility is its greatest strength.

Application Environment

Solid PTFE is the ideal choice for environments where chemical corrosion is the main concern and loads are low to moderate.

Glacier bushes excel in environments defined by high mechanical loads and abrasive wear, where a standard size can be used.

Making the Right Choice for Your Goal

To select the correct material, you must first define your primary engineering constraint.

- If your primary focus is maximum durability in a high-load, standard-sized application: The metal-backed Glacier bush is the superior choice.

- If your primary focus is creating a perfect fit for a non-standard or custom component: Solid PTFE is your only practical option due to its machinability.

- If your primary focus is chemical resistance in a low-load environment: Either option will perform well, but solid PTFE offers more design flexibility.

Ultimately, your decision is guided by balancing the need for custom fabrication against the demand for high mechanical strength.

Summary Table:

| Feature | Solid PTFE Bush | Glacier (Composite) Bush |

|---|---|---|

| Primary Advantage | Custom machinability for non-standard sizes | High mechanical strength & durability |

| Load Capacity | Low to moderate | High |

| Ideal For | Custom applications, chemical resistance | Standard-sized, high-load applications |

Need a high-performance PTFE component for your application?

Whether your priority is the extreme durability of a metal-backed composite bush for a high-load industrial application or the custom machinability of solid PTFE for a specialized medical or laboratory device, KINTEK has the expertise.

We manufacture precision PTFE components (including seals, liners, labware, and custom bushes) for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the right solution for your specific strength, chemical resistance, and customization needs.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments