At their core, PTFE mill-type envelope gaskets are used to create a robust, leak-proof seal for pipe flanges and equipment in highly corrosive or high-purity industrial environments. They are specifically engineered to combine the near-universal chemical resistance of Polytetrafluoroethylene (PTFE) with the mechanical strength of a separate core material, making them ideal for industries like chemical processing, pharmaceuticals, and food production.

The central purpose of a PTFE envelope gasket is to solve a fundamental engineering problem: how to get the unparalleled chemical inertness of PTFE without sacrificing the mechanical resilience needed to maintain a seal under pressure. It achieves this by using a PTFE "envelope" as a chemical shield over a stronger, more compressible inner core.

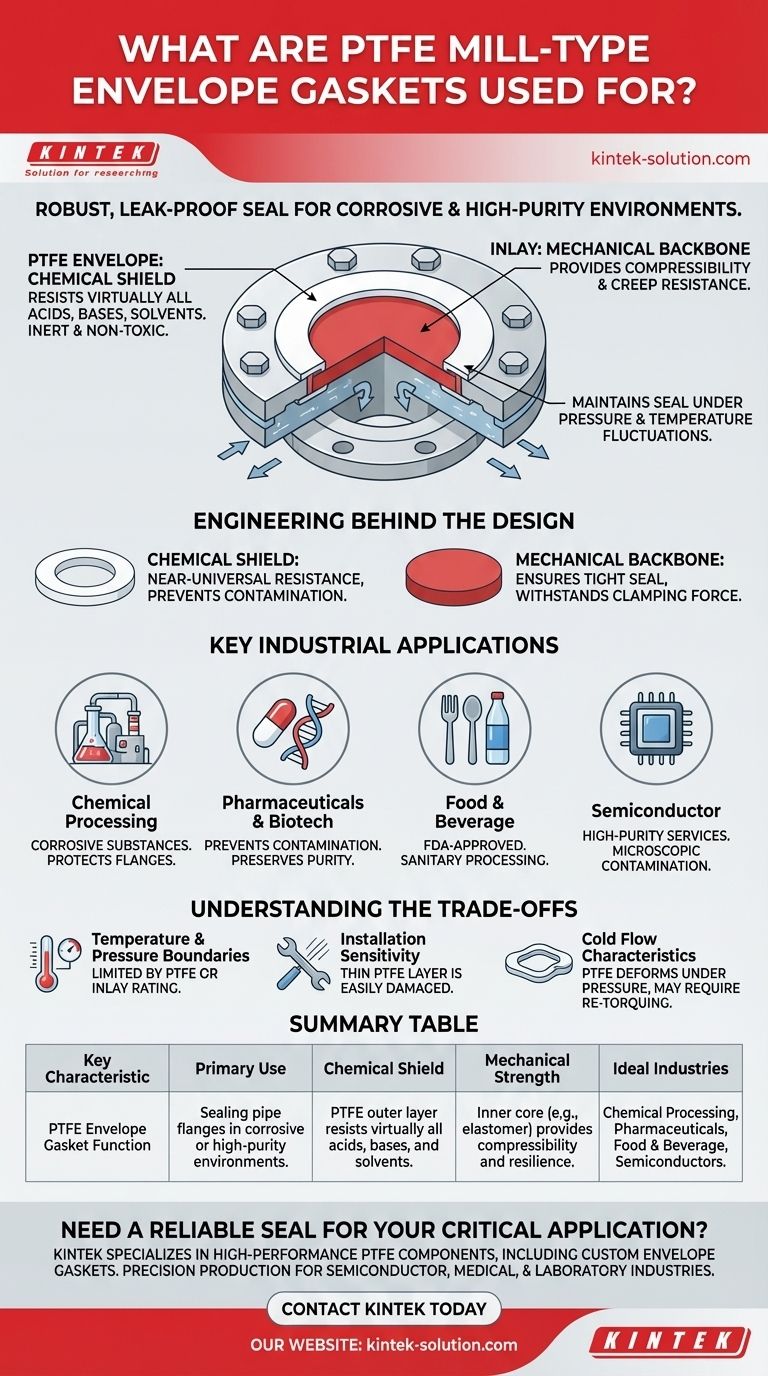

The Engineering Behind the Envelope Design

To understand where these gaskets are used, you must first understand why they are constructed this way. The two-part design is a deliberate solution for applications where a single-material gasket would fail.

The PTFE Envelope: The Chemical Shield

The outer layer, or "envelope," is made of PTFE. This material is the only part of the gasket that comes into contact with the fluid inside the pipe or vessel.

PTFE is chosen for its remarkable properties: it is resistant to nearly all acids, bases, and solvents. It is also non-toxic and has a non-stick surface, which prevents contamination.

The Inlay: The Mechanical Backbone

Inside the PTFE envelope sits a separate ring of material called an inlay or core. This core provides the mechanical strength that pure PTFE often lacks.

The inlay provides the compressibility and creep resistance necessary to withstand the clamping force of the flange bolts. This ensures the gasket maintains a tight seal over time, even under pressure fluctuations.

Key Industrial Applications

The unique construction of PTFE envelope gaskets makes them essential in several demanding sectors where product purity and chemical resistance are non-negotiable.

Chemical and Petrochemical Processing

These industries routinely handle strong acids, solvents, and other highly corrosive substances. A PTFE envelope gasket protects the flange connection from chemical attack, preventing dangerous leaks and costly downtime.

Pharmaceuticals and Biotechnology

In these fields, preventing process contamination is the highest priority. The inert, non-toxic surface of the PTFE envelope ensures that nothing from the gasket leaches into the product, preserving its purity and meeting strict regulatory standards.

Food and Beverage Manufacturing

Similar to pharmaceuticals, the food industry requires materials that are safe for direct contact with consumables. PTFE is frequently FDA-approved for these applications, making envelope gaskets a standard choice for sanitary processing lines.

High-Purity and Semiconductor Services

In applications like semiconductor manufacturing, even microscopic contamination can ruin a product. The non-reactive and high-purity nature of the PTFE surface is critical for maintaining the sterile environment required.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature and Pressure Boundaries

Although PTFE has a wide operating temperature range, it can soften at very high temperatures. The gasket's overall performance is limited by the lesser of the PTFE envelope's or the inlay's temperature and pressure rating.

Installation Sensitivity

The PTFE envelope is a relatively thin layer. It can be easily scratched or damaged by rough flange surfaces or improper handling during installation. Any damage to the envelope can create a leak path, defeating the purpose of the gasket.

Cold Flow Characteristics

PTFE has a tendency to "cold flow," or slowly deform, under sustained pressure. While the inner core is designed to mitigate this, it remains a factor. Flange bolts may require re-torquing after installation to maintain the proper sealing stress.

Making the Right Choice for Your Goal

Selecting the correct gasket requires matching its capabilities to the primary demand of your application.

- If your primary focus is aggressive chemical resistance: This gasket is an ideal choice, as the PTFE envelope isolates the joint from virtually any corrosive media.

- If your primary focus is product purity: The inert, non-toxic PTFE surface makes this gasket an essential component for food, beverage, and pharmaceutical processing.

- If your primary focus is extreme pressure and temperature: You must carefully verify the specific gasket's pressure-temperature rating to ensure both the envelope and core material can handle the service conditions.

Ultimately, selecting a PTFE envelope gasket is a strategic decision to protect critical flange connections in the most demanding chemical and high-purity environments.

Summary Table:

| Key Characteristic | PTFE Envelope Gasket Function |

|---|---|

| Primary Use | Sealing pipe flanges in corrosive or high-purity environments. |

| Chemical Shield | PTFE outer layer resists virtually all acids, bases, and solvents. |

| Mechanical Strength | Inner core (e.g., elastomer) provides compressibility and resilience. |

| Ideal Industries | Chemical Processing, Pharmaceuticals, Food & Beverage, Semiconductors. |

Need a reliable seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. We ensure precision production for industries like semiconductor, medical, and laboratory, where chemical resistance and product purity are paramount.

Whether you need prototypes or high-volume orders, our custom fabrication expertise delivers the exact seal you need.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation