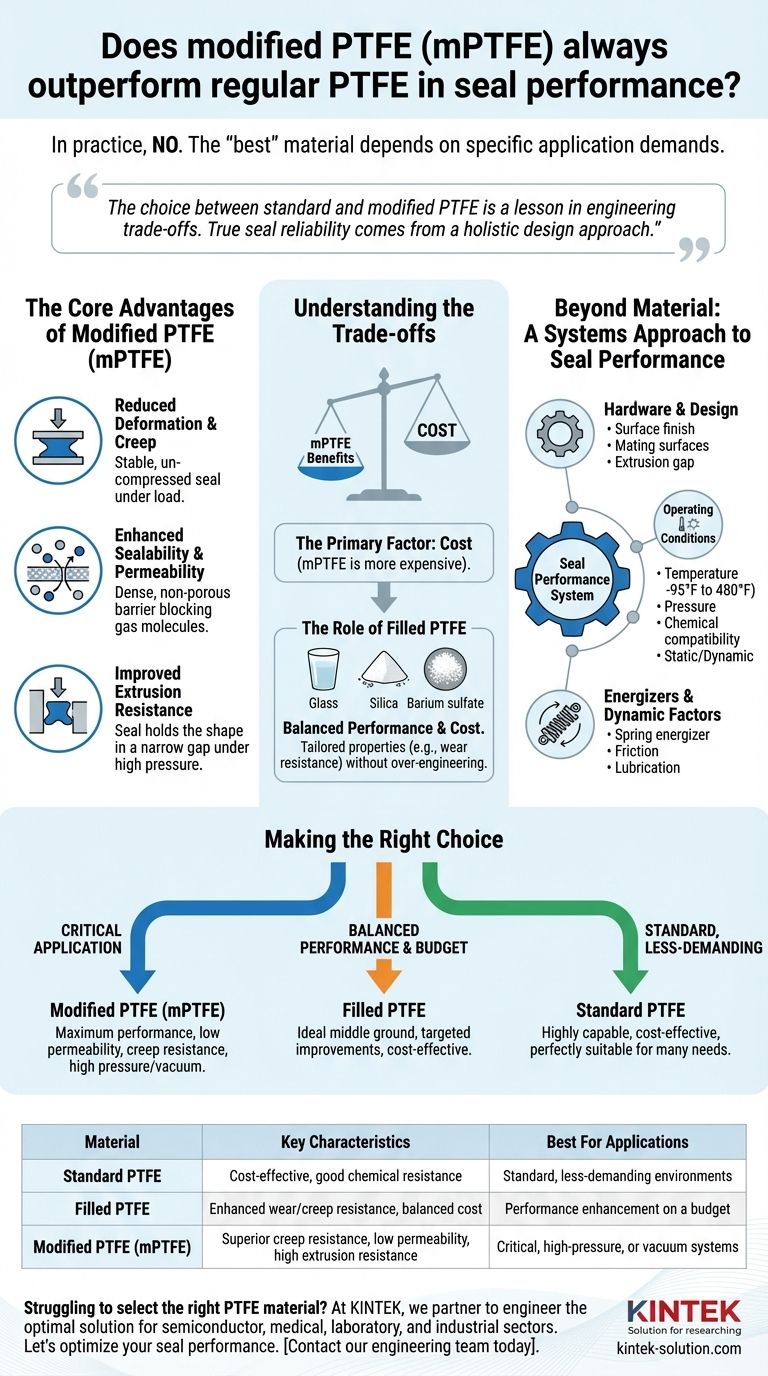

In practice, modified PTFE (mPTFE) does not always outperform standard PTFE, because the "best" material is entirely dependent on the specific demands of the application. While mPTFE offers significant enhancements in key areas like creep resistance and permeability, these benefits come at a higher cost. For many applications, the performance of standard or filled PTFE is more than sufficient, making it the more logical and economical choice.

The choice between standard and modified PTFE is a lesson in engineering trade-offs. While mPTFE provides a clear performance upgrade for demanding conditions, true seal reliability comes from a holistic design approach that considers the material, hardware, and operating environment as a single, interconnected system.

The Core Advantages of Modified PTFE (mPTFE)

Modified PTFE is a second-generation material engineered to address some of the inherent limitations of standard PTFE. The modification process, which involves adding a small amount of a comonomer, results in a denser, less porous polymer structure.

Reduced Deformation and Creep

A primary advantage of mPTFE is its significantly lower deformation under load and reduced creep (the tendency of a material to deform permanently under persistent stress).

This makes it superior in applications where the seal must maintain its shape and sealing force over long periods, especially under high pressure or thermal cycling.

Enhanced Sealability and Permeability

The denser molecular structure of mPTFE leads to better gas impermeability. This is critical in vacuum applications or systems containing gases that could otherwise escape through the microscopic pores of standard PTFE.

This quality provides a tighter, more reliable, and longer-lasting seal against both liquids and gases.

Improved Extrusion Resistance

In high-pressure applications, seals can be forced into the small clearance gap between hardware components, a failure known as extrusion.

mPTFE’s enhanced structural integrity provides superior extrusion resistance, ensuring the seal maintains its intended shape and position when subjected to high forces.

Understanding the Trade-offs

Selecting mPTFE is not an automatic decision. Its superior properties must be weighed against practical and economic factors.

The Primary Factor: Cost

The most significant trade-off is cost. The advanced manufacturing process makes mPTFE more expensive than standard PTFE.

If the application's operating conditions are not severe enough to demand its enhanced properties, specifying mPTFE results in unnecessary expense.

The Role of Filled PTFE

For applications needing more performance than standard PTFE without the full cost of mPTFE, filled PTFE is often the optimal solution.

By adding inorganic fillers like glass, silica, or barium sulfate, specific properties such as wear resistance or creep resistance can be enhanced. This allows for a tailored, cost-effective material that meets performance requirements without over-engineering.

Beyond Material: A Systems Approach to Seal Performance

Focusing solely on the polymer is a common mistake. A high-performance seal is the result of a well-designed system, where the material is only one component.

Hardware and Design

The physical environment of the seal is paramount. Factors like the surface finish of the hardware, the hardness of the mating surfaces, and the size of the extrusion gap or radial clearance have a massive impact on seal life and performance.

Even the best material will fail prematurely in a poorly designed or prepared gland.

Operating Conditions

The full range of operating conditions must be considered. While the entire PTFE family excels in a wide temperature range (from -95°F to 480°F), factors like pressure, the chemical compatibility of the media, and whether the application is static or dynamic will heavily influence material choice and seal design.

Energizers and Dynamic Factors

In many seal designs, a spring energizer provides the initial sealing force. The type of spring, its material, and its load characteristics are just as critical as the polymer jacket.

Furthermore, factors like friction and the presence or absence of lubrication must be accounted for to ensure maximum reliability and service life.

Making the Right Choice for Your Application

The decision to use standard PTFE, filled PTFE, or modified PTFE should be driven by the specific goals and constraints of your project.

- If your primary focus is maximum performance in a critical application: mPTFE is the superior choice for its low permeability, excellent creep resistance, and robust sealability under high pressure and vacuum.

- If your primary focus is balancing enhanced performance and budget: A filled PTFE grade often provides the ideal middle ground, targeting specific property improvements without the full expense of mPTFE.

- If your primary focus is a standard, less-demanding application: Standard PTFE remains a highly capable and cost-effective material that is perfectly suitable for a wide range of sealing needs.

Ultimately, selecting the right material requires a clear understanding of the entire sealing system and its specific performance demands.

Summary Table:

| Material | Key Characteristics | Best For Applications |

|---|---|---|

| Standard PTFE | Cost-effective, good chemical resistance | Standard, less-demanding environments |

| Filled PTFE | Enhanced wear/creep resistance, balanced cost | Performance enhancement on a budget |

| Modified PTFE (mPTFE) | Superior creep resistance, low permeability, high extrusion resistance | Critical, high-pressure, or vacuum systems |

Struggling to select the right PTFE material for your sealing application?

At KINTEK, we don't just sell PTFE components—we partner with you to engineer the optimal solution. Our experts will analyze your specific operating conditions, from pressure and temperature to chemical media, to recommend the perfect material—whether it's standard PTFE, a cost-effective filled grade, or high-performance modified PTFE (mPTFE).

We specialize in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, delivering precision seals, liners, and labware from prototypes to high-volume orders.

Let's optimize your seal performance and reliability. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance