In the demanding world of medical technology, PTFE fasteners are considered essential components because their unique combination of properties addresses the industry's most critical requirements. Their chemical inertness, biocompatibility, and low friction ensure operational reliability and patient safety in sterile, corrosive, and biologically sensitive environments.

The true value of PTFE fasteners is not one single attribute, but their rare convergence of capabilities. They are simultaneously inert enough for bodily contact, slick enough for moving parts, and resilient enough to withstand harsh sterilization, making them a default choice for high-stakes medical applications.

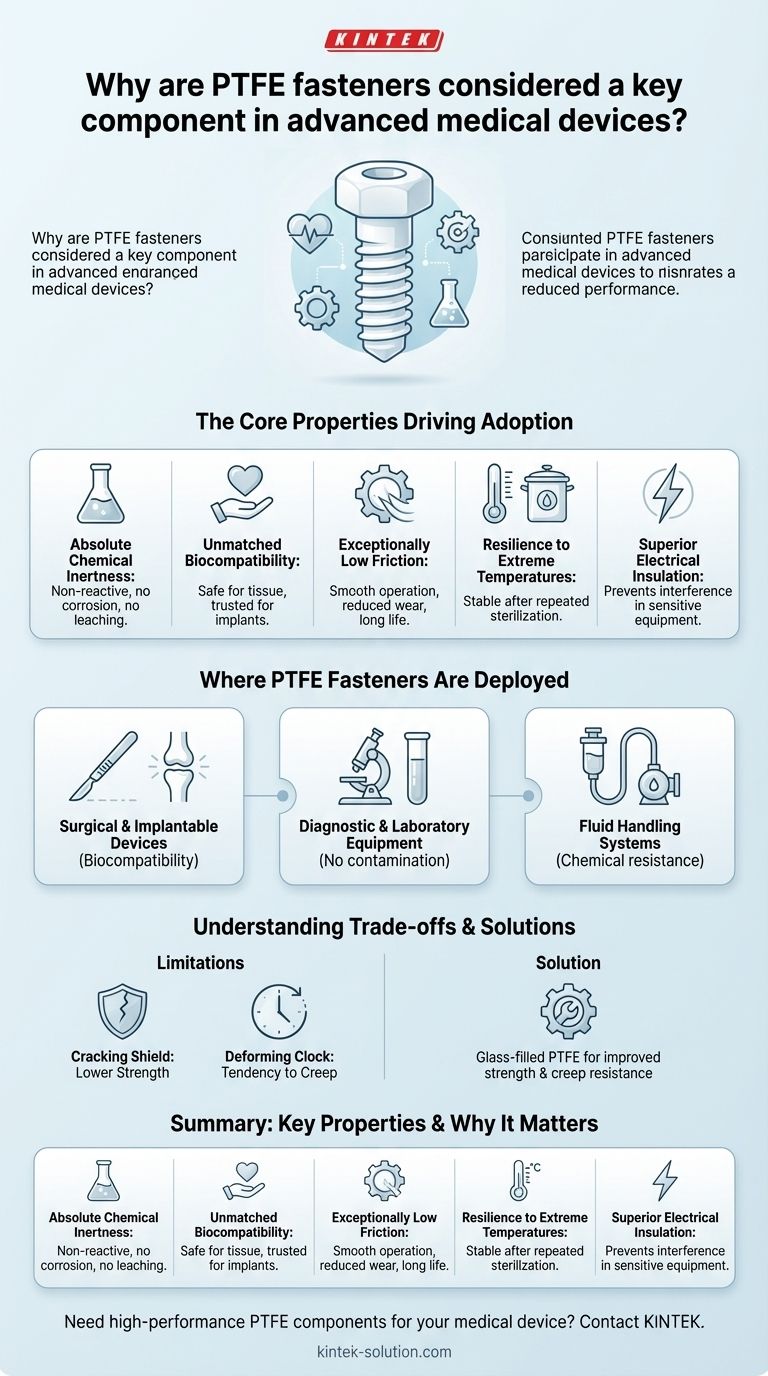

The Core Properties Driving Adoption

The selection of any material in a medical device is a decision with zero margin for error. PTFE (Polytetrafluoroethylene) possesses a distinct set of characteristics that make it uniquely suited for these challenges.

Absolute Chemical Inertness

PTFE is non-reactive with nearly all chemicals, including aggressive cleaning agents and bodily fluids. This ensures that the fastener will not corrode, degrade, or leach contaminants into the device or the patient's body.

This property is fundamental to maintaining the integrity and safety of the device over its entire lifecycle.

Unmatched Biocompatibility

Biocompatibility means a material is not harmful or toxic to living tissue. PTFE is exceptionally biocompatible, making it safe for direct and prolonged contact with the human body.

This is why it is a trusted material for use in surgical instruments, long-term implants, and other devices that interact directly with patients.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, creating a "non-stick" surface. This is critical for medical devices with moving parts, as it reduces wear and tear and ensures smooth, reliable operation.

This low-friction nature contributes significantly to the device's longevity and performance.

Resilience to Extreme Temperatures

Medical equipment must undergo stringent sterilization processes, often involving high temperatures in an autoclave. PTFE fasteners can withstand a wide range of temperatures without losing their structural integrity or properties.

This thermal stability ensures they remain reliable after repeated sterilization cycles.

Superior Electrical Insulation

In complex diagnostic and surgical equipment, preventing electrical interference is crucial for accurate readings and safe operation. PTFE is an excellent electrical insulator, effectively isolating components and preventing short circuits.

Where PTFE Fasteners Are Deployed

The theoretical benefits of PTFE translate into practical applications across a wide spectrum of advanced medical technology.

Surgical and Implantable Devices

For devices placed inside the body, such as joint replacements or cardiovascular implants, biocompatibility and chemical inertness are non-negotiable. PTFE fasteners provide secure connections without triggering an adverse reaction from the body.

Diagnostic and Laboratory Equipment

In machines that analyze blood, tissue, or other sensitive samples, preventing cross-contamination is paramount. PTFE's non-reactive and non-stick surface ensures that the fastener does not interfere with diagnostic results.

Fluid Handling Systems

Devices that manage the flow of medications, dialysis fluids, or other liquids rely on PTFE's chemical resistance. The fasteners will not break down or contaminate the fluids passing through the system.

Understanding the Trade-offs and Limitations

While PTFE offers remarkable advantages, it is not a universal solution. A technical advisor must acknowledge its limitations to ensure proper application.

Lower Mechanical Strength

Compared to metals like stainless steel or titanium, PTFE is a much softer material. It has lower tensile strength and cannot withstand the same mechanical loads as metal fasteners.

This makes it unsuitable for high-stress structural applications where mechanical failure is a primary concern.

Tendency to Creep

Under sustained pressure or load, PTFE can slowly deform over time, a phenomenon known as "creep." This must be accounted for in designs that require a fastener to maintain a constant, high clamping force.

The Role of Fillers

To mitigate some of these weaknesses, PTFE is often blended with other materials. Glass-filled PTFE, for instance, offers significantly improved strength and resistance to creep.

However, introducing a filler can alter other properties, such as its biocompatibility or chemical resistance, requiring careful evaluation for each specific use case.

Making the Right Choice for Your Application

Selecting the correct fastener material is a critical design decision that hinges on the device's primary function and environment.

- If your primary focus is biocompatibility for direct patient contact: Pure, medical-grade PTFE is the definitive choice due to its proven inertness.

- If your primary focus is mechanical performance in moving parts: A filled PTFE variant, such as glass-filled PTFE, should be considered for its superior wear resistance and strength.

- If your primary focus is preventing contamination in fluid analysis: PTFE's absolute chemical resistance makes it ideal for ensuring the purity of samples and reagents.

Ultimately, understanding the specific demands of your medical device is the key to leveraging the powerful advantages of PTFE fasteners for enhanced safety and reliability.

Summary Table:

| Key Property | Why It Matters for Medical Devices |

|---|---|

| Chemical Inertness | Resists harsh sterilization and bodily fluids, preventing corrosion and contamination. |

| Biocompatibility | Safe for direct, prolonged contact with human tissue, ideal for implants and surgical tools. |

| Low Friction | Ensures smooth operation of moving parts, reducing wear and extending device life. |

| Thermal Stability | Withstands repeated autoclave sterilization cycles without degrading. |

Need high-performance PTFE components for your medical device?

At KINTEK, we specialize in manufacturing precision PTFASTENERS, seals, liners, and custom labware for the medical, semiconductor, and laboratory industries. Whether you require the absolute biocompatibility of pure PTFE for an implantable device or the enhanced strength of a filled PTFE for a complex instrument, our custom fabrication services—from prototypes to high-volume orders—ensure your components meet the highest standards of safety and reliability.

Contact our experts today to discuss how our PTFE solutions can enhance your next medical device project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications