PTFE packing is prized for its exceptional chemical inertness and extremely low coefficient of friction. These core attributes create a durable, reliable sealing solution that excels in demanding environments. Its resistance to nearly all industrial chemicals and solvents, combined with its ability to operate across a wide temperature range, makes it a uniquely versatile choice for pumps, valves, and other rotating equipment.

Choosing the right packing material is about more than preventing leaks; it's about ensuring equipment longevity, operational efficiency, and process purity. PTFE packing addresses these deep needs by creating a durable, non-contaminating seal that minimizes wear on machinery and protects the integrity of the media being processed.

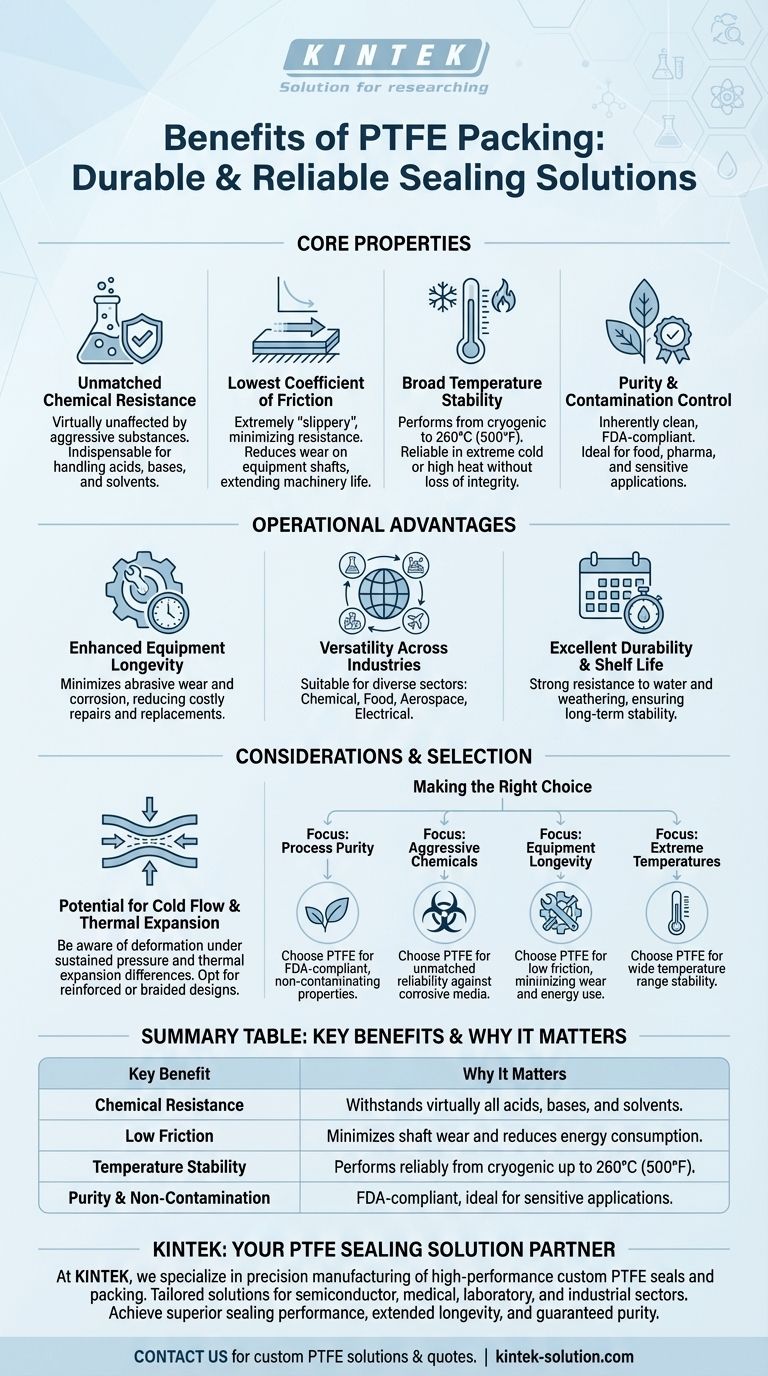

The Core Properties of PTFE Packing

The benefits of PTFE (Polytetrafluoroethylene) packing stem directly from the fundamental properties of the material itself. Understanding these characteristics clarifies why it is a preferred solution in so many critical applications.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is virtually unaffected by aggressive substances, including strong acids, bases, solvents, and other corrosive media.

This property makes it indispensable in chemical processing plants and any system handling reactive materials where other sealing materials would quickly degrade.

The Lowest Coefficient of Friction

Of all solid materials, PTFE has one of the lowest coefficients of friction. This means it is extremely "slippery," creating very little resistance against moving parts.

This directly reduces wear and scoring on equipment shafts, which extends the operational life of the machinery. As a secondary benefit, the lower friction also reduces the energy required to operate the equipment.

Broad Temperature Stability

PTFE packing performs reliably across an exceptionally wide temperature spectrum, from cryogenic conditions up to 260°C (500°F).

This thermal stability allows it to be used in processes involving extreme cold or high heat without losing its sealing integrity or becoming brittle.

Purity and Contamination Control

PTFE is a synthetic polymer that is inherently clean and does not leach or bleed color into the system.

Because of its purity and non-toxic nature, it is widely approved by the FDA for use in food processing, beverage production, and pharmaceutical manufacturing where preventing product contamination is paramount.

Operational and Economic Advantages

The inherent properties of PTFE translate into tangible benefits that impact maintenance schedules, operational costs, and overall system reliability.

Enhanced Equipment Longevity

The combination of low friction and high chemical resistance provides excellent protection for equipment. By minimizing abrasive wear on shafts and protecting components from corrosive attack, PTFE packing reduces the frequency of costly repairs and replacements.

Versatility Across Industries

PTFE's unique combination of attributes makes it suitable for a diverse range of industries. It is used in chemical plants for its inertness, in food production for its purity, in aerospace for its temperature range, and in electrical applications for its excellent insulating properties.

Excellent Durability and Shelf Life

The material exhibits strong resistance to water and weathering, ensuring it does not degrade over time. This gives PTFE packing a long and stable shelf life, making it a reliable component to keep in inventory.

Understanding the Trade-offs and Considerations

While PTFE offers significant advantages, it is essential to select the correct type for your application to ensure optimal performance. No material is a universal solution without trade-offs.

Potential for Cold Flow (Creep)

Under high, sustained pressure and temperature, standard PTFE can exhibit a tendency to "cold flow" or deform over time. However, modern PTFE packings are often braided or filled with other materials (like carbon or glass) to drastically reduce this tendency and enhance rigidity.

Thermal Expansion

PTFE has a higher rate of thermal expansion and contraction than metals. In applications with significant temperature fluctuations, this must be accounted for in the seal or joint design to maintain a consistent sealing force.

The Importance of Proper Selection

"PTFE packing" is a broad category. The performance is heavily dependent on its construction—whether it's braided, lubricated, or reinforced with other fibers. Matching the specific packing design to the application's pressure, temperature, speed, and media is critical for success.

Making the Right Choice for Your Application

Selecting the best packing material depends entirely on your primary operational goals. PTFE's strengths make it a clear choice for several common priorities.

- If your primary focus is process purity: PTFE is an ideal choice due to its FDA-compliant, non-contaminating properties.

- If your primary focus is handling aggressive chemicals: Its near-total chemical inertness provides unmatched reliability against acids, solvents, and bases.

- If your primary focus is equipment longevity and efficiency: The extremely low friction coefficient minimizes shaft wear and reduces energy consumption.

- If your primary focus is extreme temperature applications: PTFE's stability from cryogenic levels to over 260°C offers a wide and reliable operational window.

Ultimately, PTFE packing provides a superior balance of chemical resistance, low friction, and versatility, making it a foundational sealing solution for critical industries.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Chemical Resistance | Withstands virtually all acids, bases, and solvents, ensuring seal integrity in corrosive environments. |

| Low Friction | Minimizes shaft wear and reduces energy consumption, extending equipment life. |

| Temperature Stability | Performs reliably from cryogenic temperatures up to 260°C (500°F). |

| Purity & Non-Contamination | FDA-compliant and ideal for food, pharmaceutical, and semiconductor applications. |

Need a PTFE sealing solution that ensures reliability and protects your equipment?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals and packing. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution perfectly tailored to your specific pressure, temperature, and media requirements.

We serve the semiconductor, medical, laboratory, and industrial sectors, helping them achieve superior sealing performance, extended equipment longevity, and guaranteed process purity.

Contact KINTEK today to discuss your application and get a custom PTFE solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common applications of PTFE Expansion Bellows? Solve Corrosion, Temperature, and Vibration Challenges

- What regulatory standards does PTFE with fillers comply with? Ensuring Safety from Food to Pharma

- What are the main applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & High-Temp Environments

- What makes PTFE lip seals suitable for aerospace applications? Unmatched Performance in Extreme Conditions

- What are the durability benefits of PTFE washers? Achieve Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What industries commonly use PTFE-lined plug valves and why? Ensure Safety and Purity in Demanding Applications

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide