In industrial settings, PTFE expansion bellows are primarily used to handle highly corrosive fluids, operate in extreme temperature environments, and absorb vibration and misalignment in piping systems. Their unique material properties make them indispensable in demanding industries like chemical processing, pharmaceutical manufacturing, and food and beverage production.

The core value of a PTFE expansion bellow lies in its ability to protect a piping system from chemical attack, thermal stress, and mechanical shock simultaneously. It serves as a flexible, inert barrier that isolates sensitive equipment and prevents premature system failure.

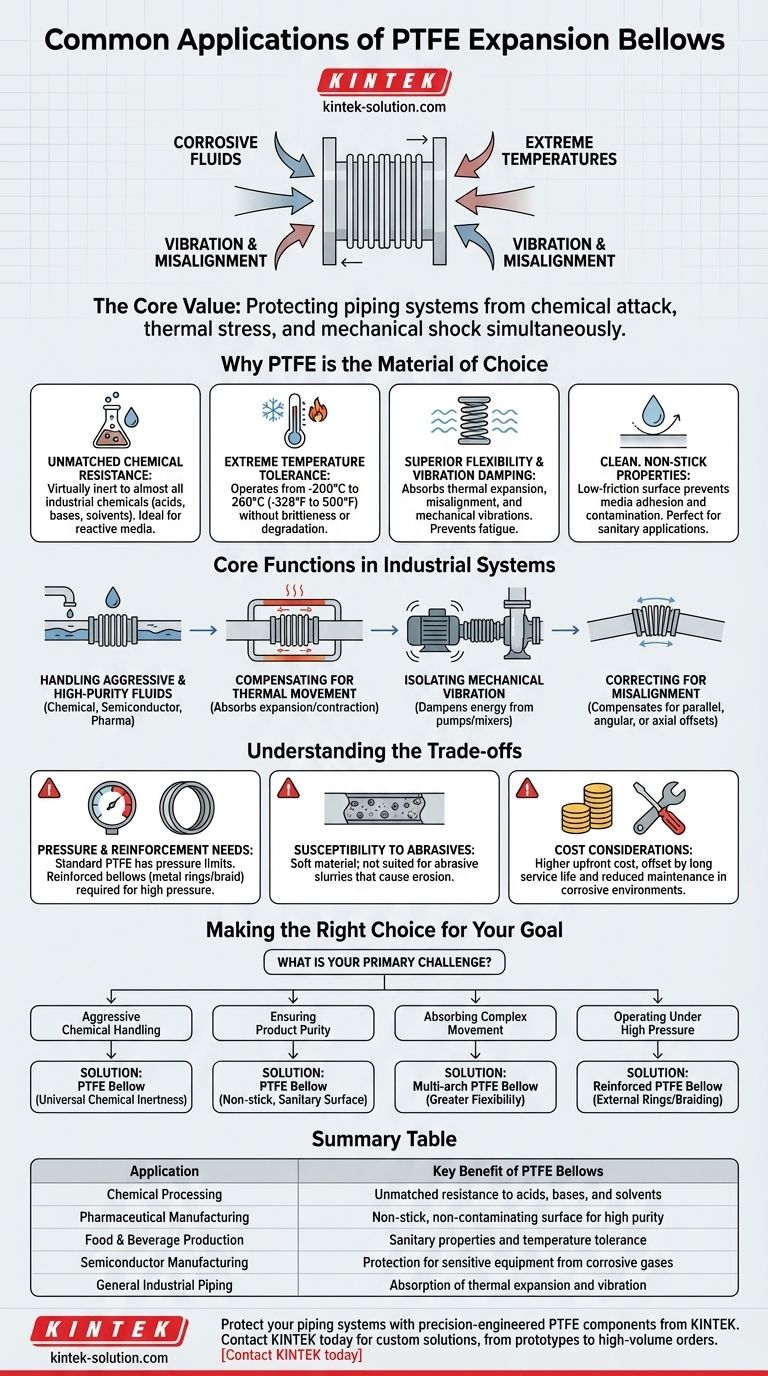

Why PTFE is the Material of Choice

The effectiveness of these components stems directly from the inherent properties of Polytetrafluoroethylene (PTFE). Understanding these characteristics is key to recognizing their ideal application.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. It can safely handle a vast range of acids, bases, and aggressive solvents that would quickly corrode metal or degrade other polymers.

This makes it the default choice for systems transporting highly reactive or corrosive media.

Extreme Temperature Tolerance

PTFE maintains its structural integrity and performance across an exceptionally wide thermal range, typically from -200 °C to 260 °C (-328 °F to 500 °F).

This allows it to be used in cryogenic applications as well as high-temperature chemical processing without becoming brittle or degrading.

Superior Flexibility and Vibration Damping

The material's flexibility allows the bellows to effectively absorb movement in multiple directions. This is critical for compensating for thermal expansion and contraction, pipe misalignment, and mechanical vibrations from pumps or motors.

By absorbing this energy, the bellow protects rigid pipes, welds, and connected equipment from fatigue and stress fractures.

Clean, Non-Stick Properties

PTFE has an extremely low-friction, non-stick surface. This prevents media from adhering to the bellow's walls, which is crucial for preventing contamination.

This property is a primary reason for its widespread use in sanitary applications within the pharmaceutical and food and beverage industries.

Core Functions in Industrial Systems

In practice, PTFE bellows are installed to solve specific, predictable problems within a piping infrastructure.

Handling Aggressive and High-Purity Fluids

Their primary role is to create a flexible connection in a pipe run that will not be compromised by the fluid it contains. This is essential in chemical plants, semiconductor manufacturing, and pharmaceutical production lines.

Compensating for Thermal Movement

Piping systems expand and contract as the temperature of the fluid or the ambient environment changes. A PTFE bellow acts as an accordion, compressing and extending to absorb this movement and prevent stress from building up in the pipe.

Isolating Mechanical Vibration

Pumps, compressors, and mixers generate constant vibration. A PTFE bellow installed at the connection point acts as a damper, isolating this vibrational energy and preventing it from propagating through and damaging the entire piping system.

Correcting for Misalignment

It is often difficult to achieve perfect alignment between two pieces of equipment or two pipe runs. A flexible bellow can compensate for minor parallel, angular, or axial misalignment, simplifying installation and preventing connection stress.

Understanding the Trade-offs

While incredibly versatile, PTFE bellows are not a universal solution. Acknowledging their limitations is critical for proper application.

Pressure and Reinforcement Needs

Standard PTFE bellows have limitations regarding internal pressure. For higher-pressure applications, reinforced bellows are required. These are typically wrapped with metal rings or a stainless steel wire braid to provide the necessary strength to prevent bursting.

Susceptibility to Abrasives

PTFE is a relatively soft material. While it excels with corrosive liquids and gases, it is not well-suited for handling abrasive slurries containing hard particulates, which can erode the material over time.

Cost Considerations

As a high-performance specialty component, PTFE expansion bellows typically have a higher upfront cost than rubber or simple metal alternatives. However, this is often offset by their long service life and reduced maintenance requirements in corrosive environments.

Making the Right Choice for Your Goal

Selecting the correct component depends entirely on the primary challenge you need to solve.

- If your primary focus is aggressive chemical handling: A PTFE bellow is almost always the correct choice due to its near-universal chemical inertness.

- If your primary focus is ensuring product purity: The non-stick, non-contaminating surface of PTFE makes it ideal for food, beverage, and pharmaceutical applications.

- If your primary focus is absorbing complex movement: Multi-arch bellows offer greater flexibility for systems with significant thermal expansion or vibration.

- If your primary focus is operating under high pressure: You must specify a reinforced PTFE bellow with external rings or braiding to ensure system safety.

Ultimately, choosing a PTFE expansion bellow is an investment in system reliability and longevity, especially where harsh conditions would cause lesser materials to fail.

Summary Table:

| Application | Key Benefit of PTFE Bellows |

|---|---|

| Chemical Processing | Unmatched resistance to acids, bases, and solvents |

| Pharmaceutical Manufacturing | Non-stick, non-contaminating surface for high purity |

| Food & Beverage Production | Sanitary properties and temperature tolerance |

| Semiconductor Manufacturing | Protection for sensitive equipment from corrosive gases |

| General Industrial Piping | Absorption of thermal expansion and vibration |

Protect your piping systems from harsh conditions with precision-engineered PTFE components from KINTEK.

Whether you're handling aggressive chemicals in a semiconductor fab, ensuring purity in a pharmaceutical line, or managing thermal stress in an industrial plant, KINTEK's custom PTFE expansion bellows are built to enhance reliability and longevity. We specialize in manufacturing high-quality PTFE seals, liners, labware, and bellows for demanding applications.

Our experts can help you select or custom-fabricate the perfect solution—from prototypes to high-volume orders—ensuring your system operates safely and efficiently.

Contact KINTEK today to discuss your specific requirements and get a quote for durable, high-performance PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications