At its core, PTFE (Polytetrafluoroethylene) lip seals are uniquely suited for aerospace applications because they reliably perform under a combination of extreme conditions that would cause most other materials to fail. Their ability to withstand wide temperature ranges, high rotational speeds, and aggressive chemicals ensures the integrity of critical systems like turbine engines, fuel pumps, and actuators.

The aerospace industry operates with zero margin for error. PTFE lip seals meet this standard by offering a rare combination of thermal stability, chemical inertness, and low-friction performance that traditional elastomeric seals simply cannot provide in such demanding environments.

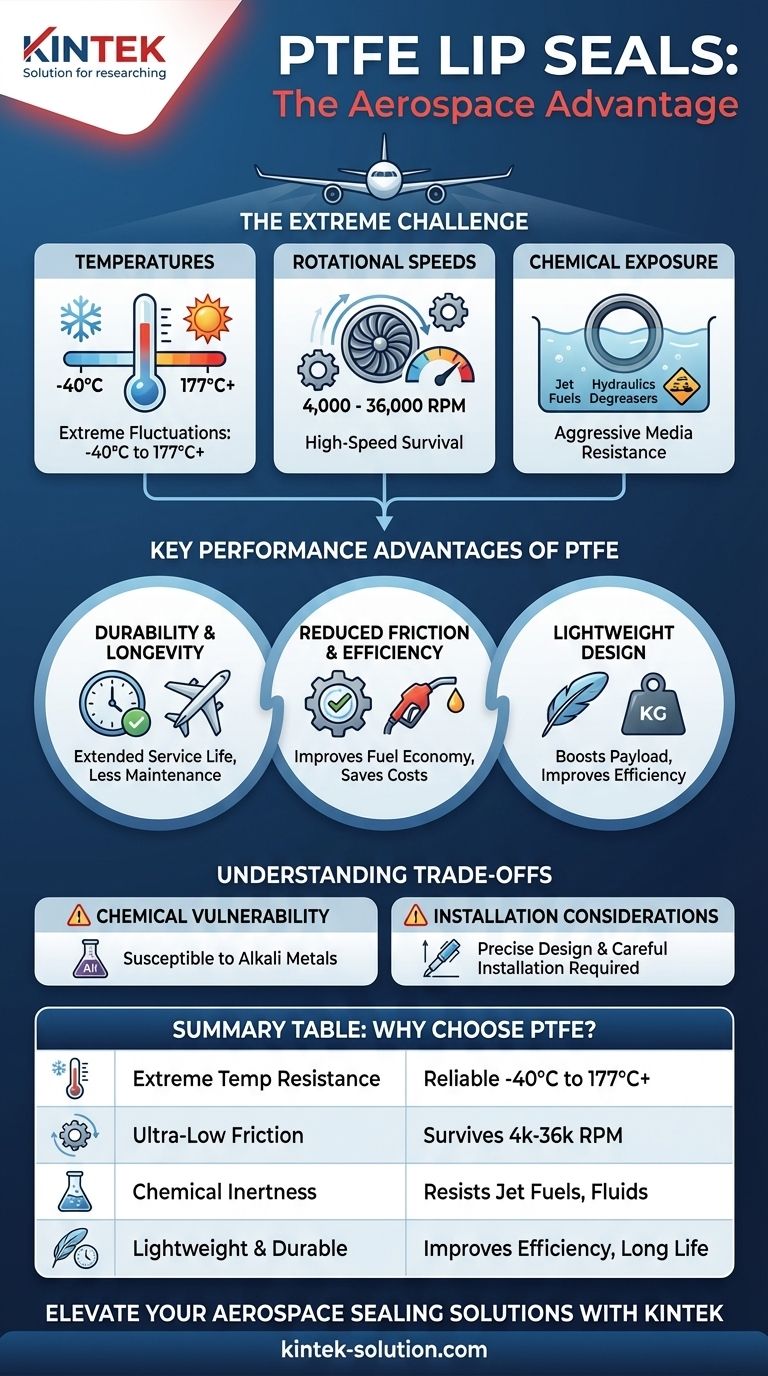

The Core Challenge: Sealing in Extreme Aerospace Environments

Aerospace components are subjected to some of the most punishing operational conditions imaginable. A seal's ability to maintain its integrity is not just a matter of performance, but of safety and reliability.

Extreme Temperature Fluctuations

Aerospace systems operate from the freezing temperatures of high-altitude flight to the intense heat generated by engines and auxiliary power units (APUs).

PTFE excels in this regard, with superb low-temperature properties and high-temperature resistance. It is proven to perform reliably in ranges from -40°C to 177°C and beyond.

High Rotational Speeds

Components like turbine engines, generators, and starters involve extremely high surface speeds, often reaching 4,000 to 36,000 RPM.

PTFE's ultra-low friction characteristics are critical here. This property minimizes heat generation and wear, allowing the seal to survive in high-speed applications where elastomeric seals would quickly overheat and degrade.

Exposure to Aggressive Chemicals

Seals in aerospace are constantly exposed to potent fluids that can break down lesser materials.

PTFE is highly chemically compatible and non-soluble. It effectively resists aggressive media like jet fuels, hydraulic fluids, and degreasers, preventing both seal degradation and contamination of sensitive systems.

Key Performance Advantages of PTFE Lip Seals

Beyond mere survival, PTFE seals provide tangible benefits that enhance overall aircraft performance, efficiency, and longevity.

Unmatched Durability and Longevity

The material's inherent toughness allows for an extended service life with very limited lubrication.

This durability reduces the frequency of maintenance and increases the reliability of essential components, from flap actuators to fuel pumps.

Reducing Friction and Improving Efficiency

The low coefficient of friction is a significant advantage. Using PTFE for coatings and seals on engine components, gears, and bearings improves the durability of these friction-prone parts.

This reduction in friction can directly improve fuel consumption. In some cases, efficiency gains can be as much as a half-gallon per mile, potentially saving an airline millions in annual operating costs.

The Benefit of Being Lightweight

Every gram counts in aircraft design. PTFE is a lightweight material, contributing to overall weight reduction without compromising strength or durability.

This helps improve the aircraft's fuel efficiency and payload capacity, a constant goal in aerospace engineering.

Understanding the Trade-offs

No material is perfect. While PTFE is an exceptional choice for its intended applications, it is essential to be aware of its specific limitations.

A Noted Chemical Vulnerability

Despite its broad chemical resistance, PTFE does have a known weakness. It is susceptible to degradation from alkali metals.

Engineers must ensure that applications involving these specific elements use an alternative sealing solution.

Design and Installation Considerations

PTFE is a relatively rigid material compared to common elastomers.

This means that seal and hardware design must be precise to ensure a proper fit. Installation often requires more care than a flexible rubber seal to avoid damaging the sealing lip.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision based on specific operational demands.

- If your primary focus is reliability in high-heat, high-speed systems (e.g., turbine engines, APUs): PTFE is the superior choice due to its thermal stability and low-friction performance under extreme dynamic loads.

- If your primary focus is longevity in chemically harsh environments (e.g., fuel pumps, hydraulic systems): PTFE's chemical inertness prevents material breakdown and ensures a long, reliable service life.

- If your primary focus is overall aircraft efficiency and weight reduction: The combination of PTFE's light weight and low-friction properties contributes directly to lower fuel consumption and reduced operating costs.

Ultimately, choosing PTFE lip seals for demanding aerospace applications is an investment in operational safety, efficiency, and long-term reliability.

Summary Table:

| Key Advantage | Benefit for Aerospace |

|---|---|

| Extreme Temperature Resistance | Reliable performance from -40°C to 177°C+ |

| Ultra-Low Friction | Survives high rotational speeds (4,000-36,000 RPM) |

| Chemical Inertness | Resists jet fuels, hydraulic fluids, and degreasers |

| Lightweight & Durable | Improves fuel efficiency and offers extended service life |

Elevate Your Aerospace Sealing Solutions with KINTEK

Choosing the right seal is critical for safety, reliability, and efficiency. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in precision production ensures your PTFE lip seals meet the exacting standards required for turbine engines, fuel pumps, and actuators. We offer custom fabrication from prototypes to high-volume orders, delivering the durability and performance your critical systems demand.

Ready to specify a seal that won't fail under pressure? Contact our engineering team today to discuss your application requirements and discover how our PTFE solutions can enhance your project's success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications