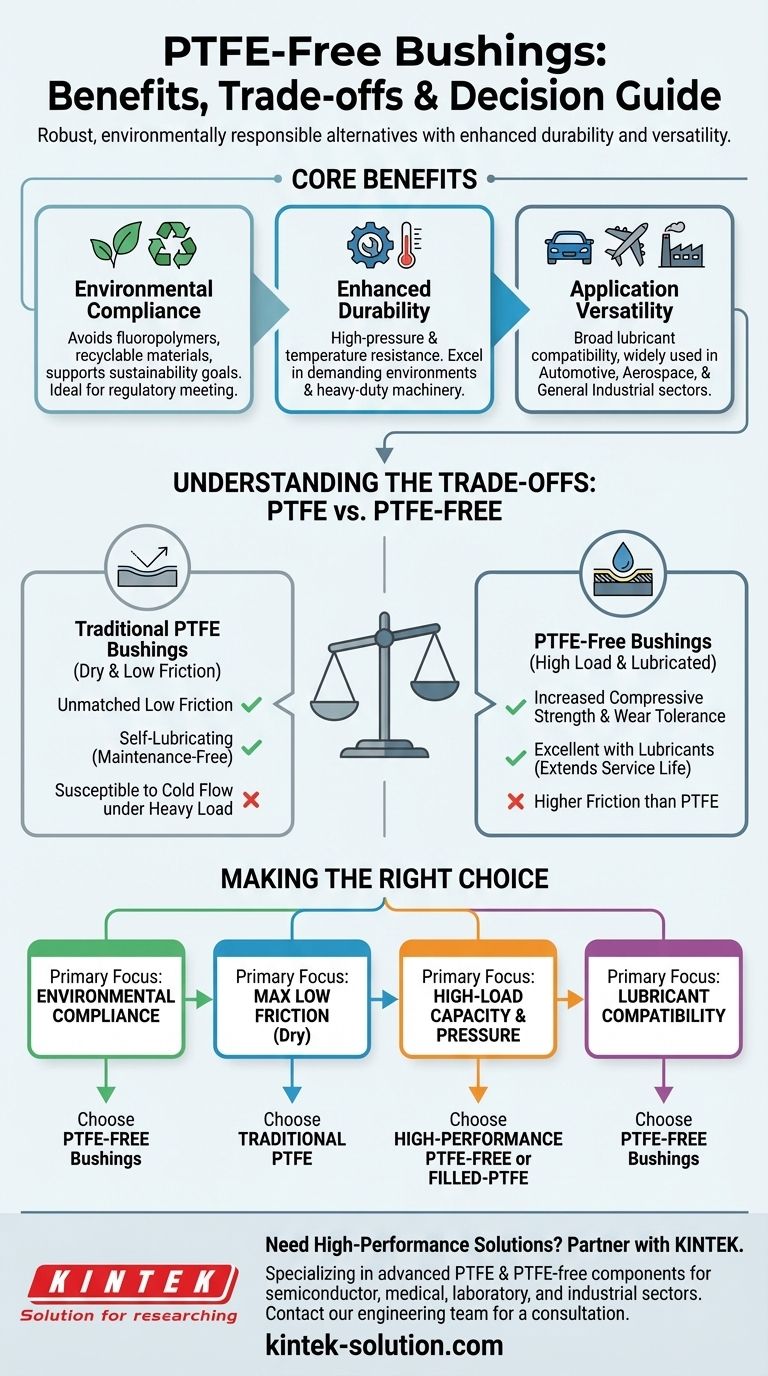

At their core, PTFE-free bushings offer a robust and environmentally responsible alternative to traditional options. Their primary benefits are enhanced durability under specific high-pressure conditions, broad versatility across industries like automotive and aerospace, and a significantly improved environmental profile that avoids the use of PTFE (polytetrafluoroethylene).

The choice between PTFE and PTFE-free bushings is not about finding a universally "better" material, but about making a precise engineering decision. PTFE-free options excel in environmental compliance and high-load durability, while traditional PTFE remains the standard for applications demanding the absolute lowest friction in a self-lubricating system.

The Primary Drivers for Adopting PTFE-Free Bushings

The shift toward PTFE-free materials is driven by a combination of regulatory pressures, performance demands, and a desire for greater application flexibility.

Environmental and Regulatory Compliance

PTFE-free bushings directly address growing concerns about the environmental impact of fluoropolymers. They reduce reliance on materials that can have harmful effects during their lifecycle.

Furthermore, many PTFE-free materials are recyclable, supporting corporate sustainability goals and helping businesses reduce their overall carbon footprint.

Enhanced Durability in Demanding Environments

These bushings are often engineered to perform where traditional PTFE might falter. They are particularly suitable for applications involving extreme temperatures and high pressures.

This makes them a reliable choice for heavy-duty industrial machinery and other systems where resistance to deformation under load is critical.

Application Versatility and Lubricant Compatibility

PTFE-free bushings are highly versatile and are successfully used in the automotive, aerospace, and general industrial sectors.

A key advantage is their compatibility with a wide range of lubricants. This contrasts with standard PTFE bushings, which are typically designed to run dry and may not perform optimally in a lubricated system.

Understanding the Trade-offs: PTFE vs. PTFE-Free

To select the right component, you must understand what you gain and what you give up. The decision is a balance of friction, load capacity, and system design.

The Unmatched Low Friction of PTFE

Traditional PTFE bushings are renowned for their extremely low coefficient of friction. They are self-lubricating and provide exceptionally smooth, quiet operation with minimal maintenance.

For applications where minimizing friction is the single most important design goal, especially in dry-running conditions, PTFE often remains the superior choice.

Load Capacity and Deformation

Standard, unfilled PTFE can be susceptible to "cold flow," or deformation under a sustained heavy load. PTFE-free materials are often specifically formulated to provide increased compressive strength and greater wear tolerance.

However, it's important to note that filled PTFE variants (such as carbon-filled PTFE) were also developed to solve this problem, offering a middle ground that improves PTFE's load-carrying capacity.

The Role of Lubrication

The need for lubrication is a fundamental design choice. PTFE bushings excel in maintenance-free, dry applications.

PTFE-free bushings, on the other hand, are often designed to work in concert with lubricants. This can be a major advantage in systems that are already lubricated, as it can extend service life and enhance performance under high loads.

Making the Right Choice for Your Application

Your specific goal will determine the ideal material. Use these guidelines to inform your decision.

- If your primary focus is environmental compliance and sustainability: Choose PTFE-free bushings to align with modern regulations and reduce your environmental impact.

- If your primary focus is maximum low-friction in a dry application: A traditional PTFE bushing is likely the most effective and efficient choice for your design.

- If your primary focus is high-load capacity and pressure resistance: Evaluate high-performance PTFE-free options or specialized filled-PTFE bushings designed for this purpose.

- If your primary focus is compatibility with an existing lubrication system: A PTFE-free bushing is generally the better-suited option, as it is designed to perform well with external lubricants.

Understanding these material distinctions empowers you to select a bushing that aligns perfectly with your design's performance, longevity, and environmental goals.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Environmental Compliance | Avoids PTFE; recyclable materials | Meeting regulations; sustainability goals |

| Enhanced Durability | High-pressure & temperature resistance | Heavy-duty machinery; demanding environments |

| Application Versatility | Broad lubricant compatibility | Automotive, aerospace, and industrial sectors |

Need High-Performance Sealing Solutions? Partner with KINTEK

Selecting the right bushing material is critical for your application's performance, longevity, and compliance. At KINTEK, we specialize in the precision manufacturing of advanced PTFE and PTFE-free components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the nuanced trade-offs between low friction, load capacity, and environmental goals. Our expertise ensures you get a component perfectly tailored to your needs, from prototype to high-volume production.

Let us help you optimize your design. Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- What type of thermoplastic is Teflon and what are its inherent properties? | A Guide to PTFE's Unique Strengths

- What makes PTFE plugs durable? Unmatched Chemical and Temperature Resistance

- What role does chemical stability play in the performance of Teflon gland fillers? Ensure Long-Term Reliability in Harsh Environments

- How does the operating mechanism of PTFE lined butterfly valves work? A Guide to Corrosion-Resistant Flow Control

- What are some examples of chemicals with Excellent (A) resistance for all filler types in Filled PTFE? | Key Compatible Chemicals

- What are the main application areas of PTFE O-ring seals? Critical Seals for Demanding Industries

- What are the main advantages of PTFE diaphragm valves in the pharmaceutical industry? Ensure Purity, Sterility, and Reliability

- What are the key properties of PTFE valves for food processing? Ensure Safety, Purity, and Efficiency