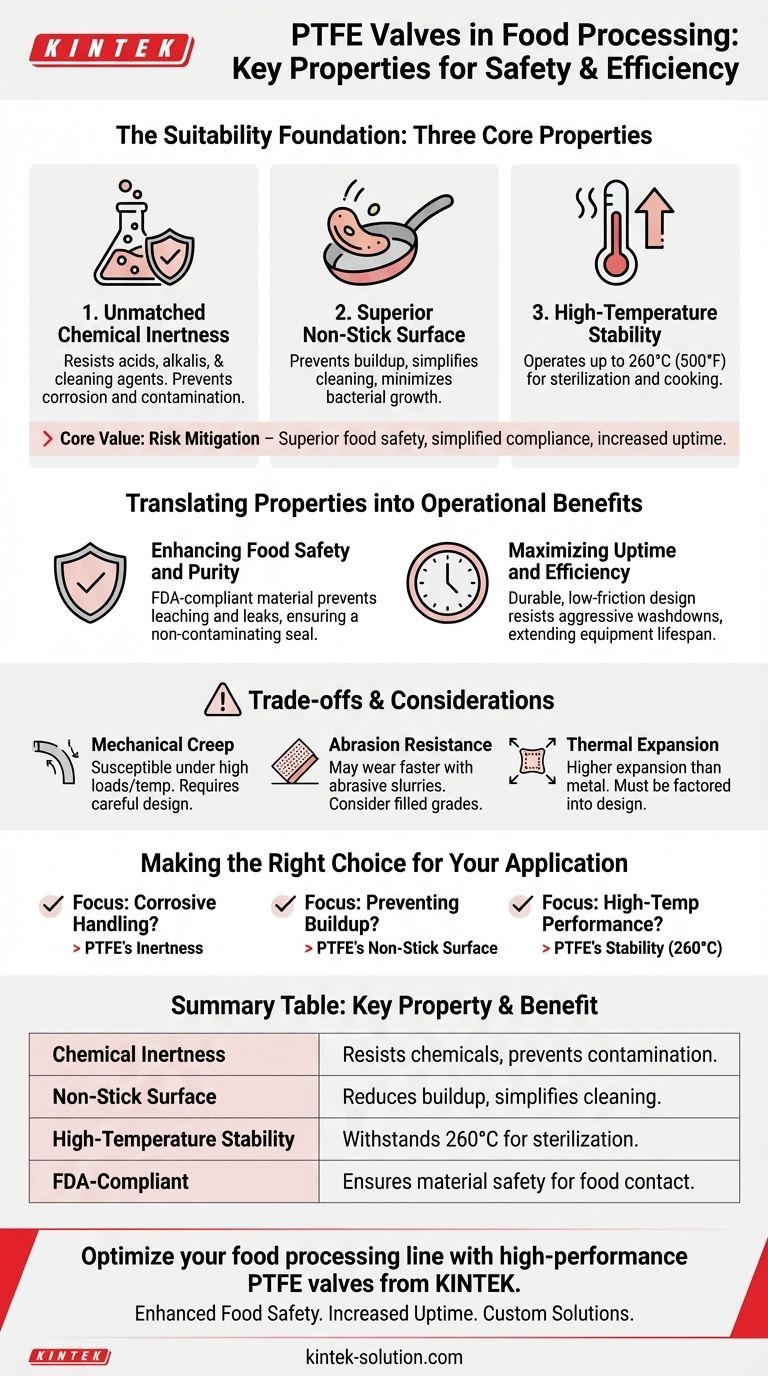

The suitability of PTFE valves in the food processing industry is fundamentally due to three key properties: their exceptional chemical inertness, their high-temperature stability, and their non-stick surface. This unique combination ensures that the valve material does not react with food products or cleaning agents, withstands process conditions like sterilization, and prevents material buildup that could lead to contamination.

While its technical specifications are impressive, the core value of PTFE in food processing is its ability to mitigate risk. Its inert and non-stick nature directly translates to superior food safety, simplified regulatory compliance, and increased operational uptime.

The Foundation: Why PTFE Excels in Hygienic Environments

To understand PTFE's role, we must look at how its core material properties address the primary challenges of food production: purity, safety, and efficiency.

Unmatched Chemical Inertness

PTFE (polytetrafluoroethylene) is highly resistant to a vast range of chemicals. This includes acidic substances like citrus or tomato-based products, alkaline solutions, and the aggressive cleaning agents used in sanitation protocols.

This inertness is critical because it ensures the valve material itself does not degrade, corrode, or leach any substances into the food product, preserving its purity and safety.

Superior Non-Stick Properties

The famous non-stick quality of PTFE is invaluable in food processing. This property prevents food particles, thick liquids, and other residues from adhering to the valve's internal surfaces.

This results in a cleaner system that is less prone to bacterial growth and cross-contamination between batches. It also dramatically simplifies and speeds up cleaning cycles.

Wide Operational Temperature Range

PTFE components perform reliably in temperatures up to 260°C (500°F).

This thermal stability makes them suitable for a wide array of food processing applications, from high-temperature cooking and pasteurization to steam-in-place (SIP) cleaning and sterilization procedures.

Translating Properties into Operational Benefits

These fundamental properties deliver tangible advantages in a food processing plant, directly impacting safety, productivity, and compliance.

Enhancing Food Safety and Purity

Materials used in food processing equipment must often be FDA-compliant, and PTFE meets this standard. Its strong atomic structure prevents it from bonding with or absorbing food materials.

This ensures a tight, reliable seal that prevents leaks, which could compromise food safety or lead to product loss. The valve becomes a non-contaminating component in the process line.

Maximizing Uptime and Efficiency

PTFE valves are highly durable and exhibit minimal friction, which reduces wear on moving parts and extends the equipment's lifespan.

Their resistance to high-pressure washdowns and aggressive cleaning cycles means less downtime for maintenance or replacement, directly boosting plant productivity.

Understanding the Trade-offs and Considerations

While PTFE is an exceptional material, no single solution is perfect for every scenario. An objective assessment requires understanding its limitations.

Mechanical Strength and Creep

PTFE is a relatively soft material. Under high mechanical loads, especially at elevated temperatures, it can be susceptible to "creep," which is a slow deformation over time. Valve design and seat engineering must account for this.

Abrasion Resistance

For applications involving highly abrasive slurries (e.g., certain grains or mineral-fortified products), PTFE may wear more quickly than harder materials. In such cases, a different valve type or a filled grade of PTFE might be a better choice.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This means it expands and contracts more significantly with temperature changes. This property must be factored into the design of the valve and its installation to ensure a consistent seal across all operating temperatures.

Making the Right Choice for Your Application

Selecting the right valve material is a critical decision that impacts your entire operation. Your choice should align with your most pressing operational goals.

- If your primary focus is handling corrosive ingredients and aggressive cleaning agents: PTFE's chemical inertness is its most critical advantage, ensuring system integrity and preventing product contamination.

- If your primary focus is preventing product buildup and ensuring fast cleanup: The non-stick surface of PTFE minimizes downtime between batches and simplifies compliance with hygiene protocols.

- If your primary focus is maintaining performance across high-temperature processes: PTFE's thermal stability up to 260°C makes it a reliable choice for applications involving cooking, pasteurization, or steam cleaning.

Ultimately, selecting PTFE is an investment in the safety, purity, and efficiency of your food processing operation.

Summary Table:

| Key Property | Benefit in Food Processing |

|---|---|

| Chemical Inertness | Resists acids, alkalis, and cleaning agents; prevents contamination and corrosion. |

| Non-Stick Surface | Reduces product buildup, simplifies cleaning, and minimizes bacterial growth. |

| High-Temperature Stability | Withstands up to 260°C (500°F) for cooking, pasteurization, and sterilization. |

| FDA-Compliant | Ensures material safety and regulatory compliance for food contact. |

Optimize your food processing line with high-performance PTFE valves from KINTEK.

Our precision-manufactured PTFE components—including seals, liners, and custom valves—are engineered to meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors. By choosing KINTEK, you benefit from:

- Enhanced Food Safety: Chemically inert, non-stick surfaces prevent contamination and simplify compliance.

- Increased Uptime: Durable, low-friction designs reduce maintenance and extend equipment life.

- Custom Solutions: We offer tailored fabrication from prototypes to high-volume orders to fit your exact needs.

Contact us today to discuss how our PTFE valves can safeguard your products and boost your operational efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components