At its core, the chemical stability of a Teflon gland filler is its most critical performance characteristic. This inherent inertness means the filler material will not react with, degrade, or be dissolved by the vast majority of industrial chemicals, ensuring the seal remains intact and the system operates reliably without contamination or failure.

The central challenge in any industrial sealing application is preventing failure when exposed to harsh conditions. The chemical stability of Teflon (PTFE) is the foundation of its performance, guaranteeing the material's integrity and providing a dependable, long-lasting seal across an unparalleled range of chemical environments.

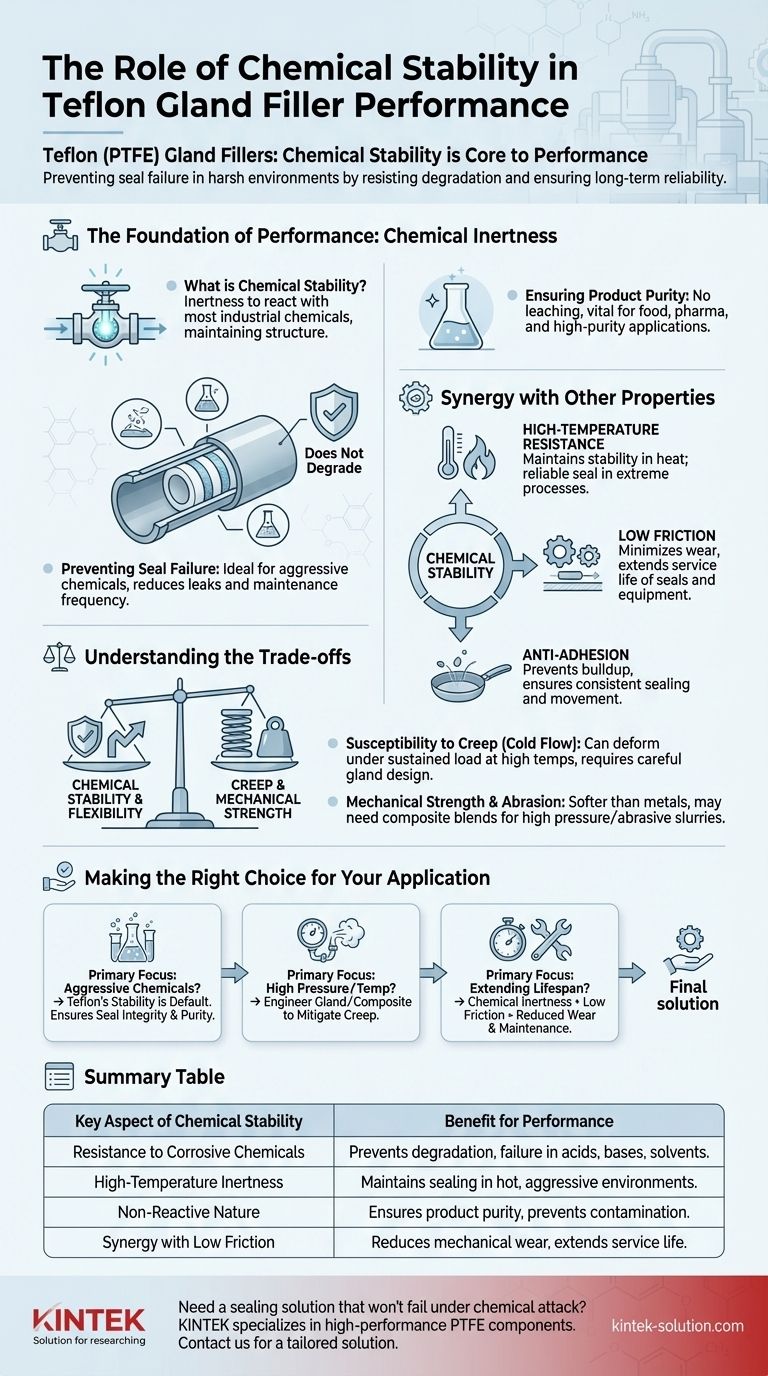

The Foundation of Performance: Chemical Inertness

The term "gland filler" or "packing" refers to a sealing material used to prevent leakage from valves, pumps, and other rotating or reciprocating equipment. The choice of material is paramount to its success.

What is Chemical Stability?

Chemical stability, or inertness, is the property of a substance to resist chemical reaction when it comes into contact with other substances.

For Teflon, this means it maintains its physical and chemical structure even when exposed to highly corrosive acids, bases, solvents, and oxidizers. The material simply does not degrade.

Preventing Seal Failure in Corrosive Environments

In applications like chlorine treatment systems or equipment handling strong acids, a reactive sealing material would quickly break down, leading to catastrophic leaks.

Teflon's chemical stability ensures it can be used for extended periods in these aggressive environments without significant wear, directly preventing equipment failure and reducing maintenance frequency.

Ensuring Product Purity

Because Teflon fillers do not react with the substances they are sealing, they do not leach impurities into the process fluid.

This is a non-negotiable requirement in industries like food and beverage, pharmaceuticals, and high-purity chemical manufacturing, where any contamination could ruin an entire batch.

How Chemical Stability Synergizes with Other Properties

While chemical inertness is the cornerstone, it works in concert with Teflon's other unique properties to deliver exceptional overall performance. It's the combination of these factors that makes it such a versatile sealing solution.

Synergy with High-Temperature Resistance

Many industrial processes, such as oil refining or high-temperature steam processing, involve both corrosive chemicals and extreme heat.

Teflon's ability to maintain its chemical stability at high temperatures allows it to provide a reliable seal where many other materials would fail from either chemical attack or thermal degradation.

The Role of Low Friction

Teflon possesses an extremely low coefficient of friction, one of the lowest of any solid material. Chemical stability prevents material degradation, while low friction minimizes physical wear between sealing components.

This dual resistance to both chemical and mechanical stress is what gives Teflon gland fillers their exceptionally long service life, reducing friction losses in pumps and extending the lifespan of valve stems.

Superior Sealing and Anti-Adhesion

A chemically stable material maintains its intended shape and surface properties over time. This ensures a consistent, tight seal.

Furthermore, Teflon's anti-adhesion (non-stick) properties prevent process media from building up on the filler material, which could otherwise impede movement and compromise the seal.

Understanding the Trade-offs

No material is perfect for every scenario. While Teflon's chemical stability is nearly universal, its mechanical properties present specific limitations that must be considered in engineering design.

Susceptibility to Creep (Cold Flow)

The primary trade-off for Teflon's flexibility and inertness is its susceptibility to creep, or "cold flow." Under sustained compressive load, especially at elevated temperatures, the material can slowly deform.

This requires careful design of the gland and proper installation procedures to ensure the seal remains tight over its service life.

Mechanical Strength and Abrasion

Compared to metals or some advanced polymers, pure Teflon has lower mechanical strength and is softer. It may not be suitable for applications with extremely high pressures or those involving abrasive slurries.

In these cases, packings made from Teflon fibers blended with other materials like carbon or graphite are used to enhance mechanical robustness while retaining excellent chemical resistance.

Making the Right Choice for Your Application

Selecting the correct gland filler requires balancing the chemical environment with the mechanical and thermal demands of the system.

- If your primary focus is handling aggressive chemicals: Teflon's unmatched chemical stability makes it the default choice, ensuring seal integrity and preventing process contamination.

- If your primary focus is high-pressure or high-temperature service: Ensure the gland design and selected Teflon grade (or composite) are engineered to mitigate creep and maintain sealing force.

- If your primary focus is extending equipment lifespan: The combination of Teflon's chemical inertness and low friction directly reduces both chemical degradation and mechanical wear, minimizing maintenance.

Ultimately, understanding the foundational role of chemical stability empowers you to specify a sealing solution that delivers predictable, long-term reliability in your most demanding applications.

Summary Table:

| Key Aspect of Chemical Stability | Benefit for Teflon Gland Filler Performance |

|---|---|

| Resistance to Corrosive Chemicals | Prevents degradation and seal failure in acids, bases, and solvents. |

| High-Temperature Inertness | Maintains sealing integrity in hot, aggressive environments. |

| Non-Reactive Nature | Ensures product purity by preventing contamination in sensitive processes. |

| Synergy with Low Friction | Reduces mechanical wear, extending service life beyond chemical resistance alone. |

Need a sealing solution that won't fail under chemical attack? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland fillers and seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a chemically inert, reliable seal designed for your specific harsh environment. Contact us today to discuss your application and receive a tailored solution that guarantees long-term reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems