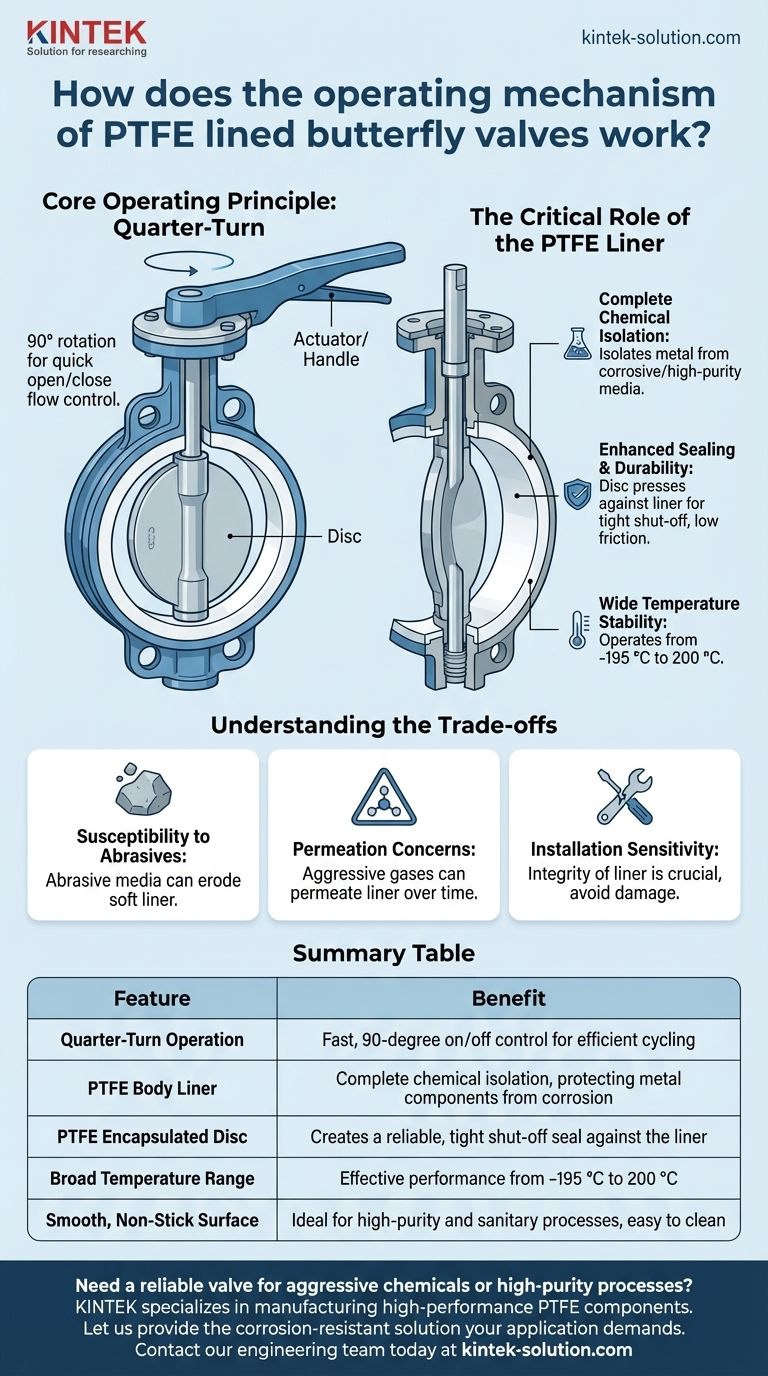

At its core, a PTFE lined butterfly valve operates on a simple quarter-turn principle. A circular disc, known as the "butterfly," is positioned in the center of the valve body. This disc is connected by a stem to an external handle or actuator, which rotates the disc 90 degrees to either fully open or fully close the flow path.

The true value of this design lies not just in its mechanical simplicity, but in its protective PTFE lining. This inert liner isolates the valve's metal components from corrosive or high-purity media, ensuring both valve longevity and process integrity.

The Core Operating Principle

The operation of a butterfly valve is fundamentally straightforward and efficient, designed for quick shut-off and flow control.

The Disc and Stem

The central component is the disc, which pivots on a central axis. This disc is connected to a stem, a rod that extends outside the valve body to connect with an actuator.

The Quarter-Turn Mechanism

When the handle or actuator is turned, the stem rotates the disc. A 90-degree turn moves the disc from a position perpendicular to the flow (closed) to one parallel to the flow (open). This quick action is ideal for applications requiring rapid on/off cycling.

The Actuator

The valve is operated by an actuator, which can be a simple manual handwheel or lever. For automated processes, pneumatic or electric actuators can be used to control the valve remotely.

The Critical Role of the PTFE Liner

While the mechanics are simple, the polytetrafluoroethylene (PTFE) liner is what defines this valve and makes it suitable for demanding applications.

Complete Chemical Isolation

The PTFE is molded to the interior of the valve body, creating a seamless, non-reactive barrier. This liner ensures the process fluid—whether it's a harsh acid, an alkali, or a high-purity pharmaceutical ingredient—only ever touches the inert PTFE. This protects the structural metal body from corrosion.

Enhanced Sealing and Durability

The disc also often has a PTFE or PFA encapsulation. When the valve closes, this disc presses firmly against the liner, creating a reliable, tight shut-off that prevents leaks. The low-friction nature of PTFE also reduces wear and tear during operation, extending the valve's service life.

Wide Temperature Stability

PTFE provides excellent performance across a broad temperature range, typically operating effectively between -195 °C and 200 °C. This makes it suitable for both cryogenic and moderately high-temperature processes without degrading.

Understanding the Trade-offs

While highly effective, PTFE lined valves have specific limitations that are important to understand for proper application.

Susceptibility to Abrasives

The primary weakness of a soft liner like PTFE is its low resistance to abrasive media. Slurries containing hard particles can quickly erode or damage the liner, compromising the valve's seal and protective barrier.

Permeation Concerns

While highly resistant, PTFE is not completely impermeable. Certain aggressive gases or chemicals can, over time, permeate through the liner at high temperatures and pressures, potentially reaching the valve body.

Installation Sensitivity

The integrity of the valve depends entirely on the integrity of the liner. Care must be taken during installation to avoid scratching or gouging the PTFE, as any damage can create a path for corrosive media to attack the underlying metal.

Making the Right Choice for Your Application

Selecting the right valve depends entirely on the specific demands of your process.

- If your primary focus is handling corrosive chemicals: The PTFE liner's chemical inertness provides the robust protection you need for acids, solvents, and other aggressive media.

- If your primary focus is high-purity or sanitary processes: The non-reactive, smooth surface of PTFE is ideal for pharmaceutical or food production, preventing contamination and ensuring easy cleaning.

- If your primary focus is general utility in a non-corrosive system: A standard, unlined butterfly valve may be a more cost-effective solution, as the advanced chemical protection of PTFE is not required.

Ultimately, the PTFE lined butterfly valve is an engineered solution designed to provide reliable flow control in environments where standard valves would quickly fail.

Summary Table:

| Feature | Benefit |

|---|---|

| Quarter-Turn Operation | Fast, 90-degree on/off control for efficient cycling |

| PTFE Body Liner | Complete chemical isolation, protecting metal components from corrosion |

| PTFE Encapsulated Disc | Creates a reliable, tight shut-off seal against the liner |

| Broad Temperature Range | Effective performance from -195 °C to 200 °C |

| Smooth, Non-Stick Surface | Ideal for high-purity and sanitary processes, easy to clean |

Need a reliable valve for aggressive chemicals or high-purity processes?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our expertise in precision production ensures that your components—from prototypes to high-volume orders—meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

Let us provide the corrosion-resistant solution your application demands.

Contact our engineering team today to discuss your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining