In short, Polytetrafluoroethylene (PTFE) O-rings and seals are used in the most demanding industrial environments. Their primary applications are found in the machinery, automotive, aerospace, chemical, and medical industries, specifically in systems involving aggressive chemicals, extreme temperatures, or dynamic motion where low friction is critical.

The widespread use of PTFE is not accidental; it is a direct result of its unique combination of extreme chemical resistance, broad temperature stability, and exceptionally low friction. These properties make it the default choice for sealing applications where conventional elastomers would quickly fail.

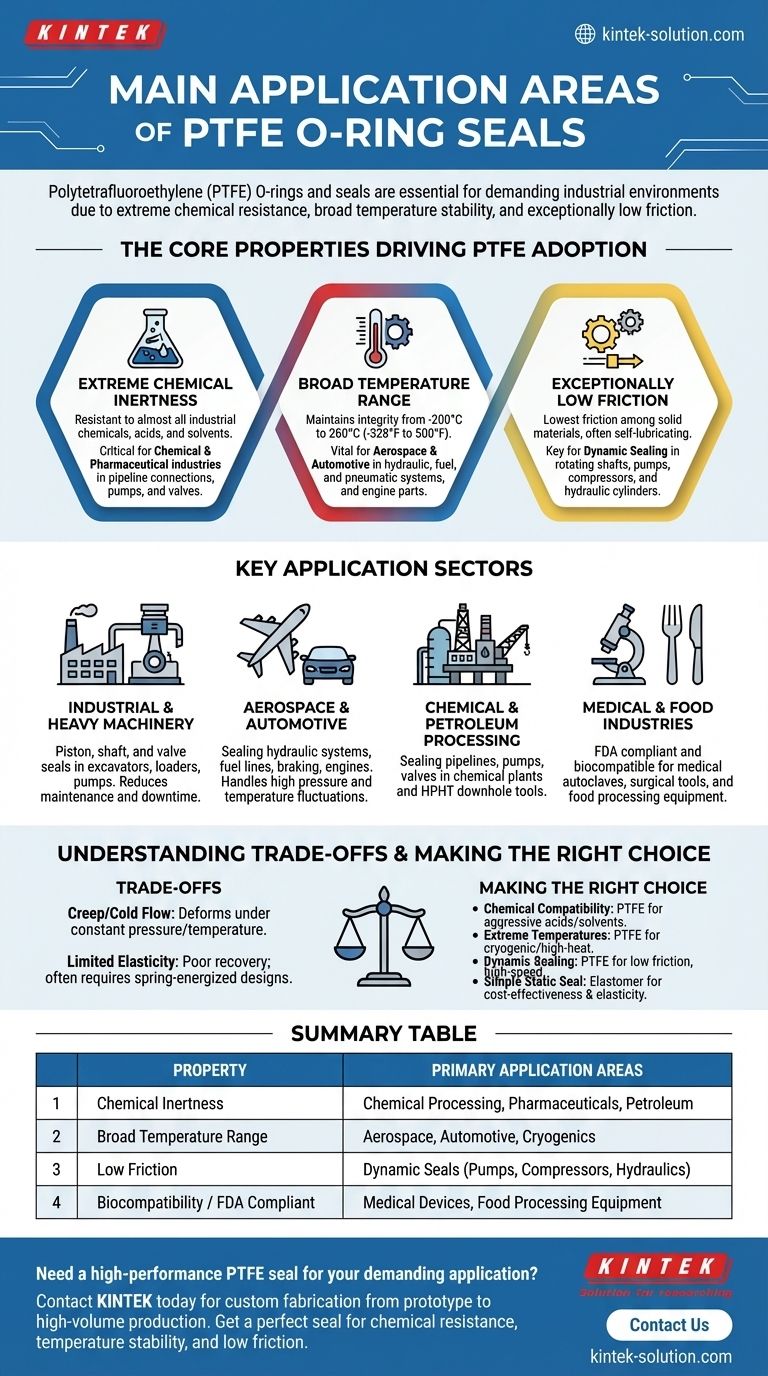

The Core Properties Driving PTFE Adoption

To understand where PTFE seals are used, you must first understand why they are chosen over more common materials like rubber. Their selection is almost always driven by one or more of their three defining characteristics.

### Extreme Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential material in environments that would destroy other seals.

This property is critical for applications in the chemical and pharmaceutical industries, such as in pipeline connections, pump housings, and valve seals that handle aggressive substances.

### Broad Temperature Range

PTFE seals maintain their integrity and performance across an exceptionally wide temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This stability is crucial for the aerospace industry in hydraulic, fuel, and pneumatic systems, as well as in automotive engine and transmission systems where extreme heat is generated. It also allows for use in cryogenic applications.

### Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is inherent and does not require external lubrication.

This feature is vital for dynamic sealing applications involving rotating shafts or moving pistons. It reduces wear, minimizes heat generation, and improves the overall efficiency of machinery like screw compressors, pumps, and hydraulic cylinders.

A Breakdown of Key Application Sectors

These core properties translate directly into use cases across several high-stakes industries where performance and reliability are non-negotiable.

### Industrial and Heavy Machinery

In equipment like excavators, loaders, pumps, and compressors, PTFE seals are used as piston seals, shaft seals, and valve seals. Their durability and wear resistance reduce maintenance frequency and costly downtime.

### Aerospace and Automotive

These sectors rely on PTFE for sealing hydraulic systems, fuel lines, braking systems, and engines. The material's ability to withstand high pressure and extreme temperature fluctuations ensures operational safety and reliability.

### Chemical and Petroleum Processing

PTFE is the material of choice for sealing pipeline connections, pump bodies, and valves in chemical plants. In the petroleum industry, its resilience makes it ideal for downhole tools and subsea equipment operating in high-pressure, high-temperature (HPHT) environments.

### Medical and Food Industries

Due to its inert nature and biocompatibility, PTFE is compliant with FDA regulations. This makes it suitable for medical devices like hematology analyzers, autoclaves, and surgical tools, as well as for hygienic equipment in food processing plants. Its non-stick surface also prevents contaminant build-up.

Understanding the Trade-offs

Despite its advantages, PTFE is not a universal solution. Its mechanical properties present specific limitations that engineers must account for.

### Creep and Cold Flow

Under constant pressure and temperature, pure PTFE can slowly deform over time, a phenomenon known as creep or cold flow. This can lead to a loss of sealing force in certain static applications.

### Limited Elasticity

Unlike rubber elastomers, PTFE has very poor "elastic memory." It does not spring back to its original shape effectively after being compressed. This is why many PTFE seals are spring-energized—a metal spring provides the constant outward force that the PTFE material itself cannot.

Making the Right Choice for Your Environment

Choosing a sealing material requires matching its properties to the operational demands of the application.

- If your primary focus is chemical compatibility: PTFE is often the only viable choice for sealing aggressive acids, solvents, and industrial chemicals.

- If your primary focus is extreme temperatures: PTFE's performance in both cryogenic and high-heat applications makes it ideal for aerospace and specialized industrial processes.

- If your primary focus is dynamic sealing with low friction: PTFE is superior for high-speed rotating shafts in pumps and compressors where minimizing wear and heat is critical.

- If your primary focus is a simple static seal in a moderate environment: A traditional elastomer O-ring is often a more cost-effective and suitable solution due to its superior elasticity.

Ultimately, understanding PTFE's core strengths—chemical, thermal, and frictional resistance—allows you to specify it with confidence in the most demanding applications.

Summary Table:

| Key Property | Primary Application Areas |

|---|---|

| Chemical Inertness | Chemical Processing, Pharmaceuticals, Petroleum |

| Broad Temperature Range (-200°C to 260°C) | Aerospace, Automotive, Cryogenics |

| Low Friction | Dynamic Seals in Pumps, Compressors, Hydraulic Systems |

| Biocompatibility / FDA Compliant | Medical Devices, Food Processing Equipment |

Need a high-performance PTFE seal for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get a perfect seal, from prototype to high-volume production, that meets your exact requirements for chemical resistance, temperature stability, and low friction.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat